Plastic Decks/Green BuildingWood Plastic

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

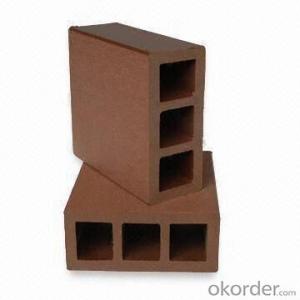

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, Gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: How does the floor stand up?

- It is only for the other no better way to recommend living room or floor tiles better

- Q: How to choose a solid wood flooring

- According to the floor and hobbies, the use of deducted solid wood composite floor, small gap, more solid

- Q: We are putting in maple floors and are considering engineered wood. Trying to research the engineered floors, I see alot of positives and not the negatives - yet there must be some! Any opinions?Also - would one be easier to install than the other?If it matters ... This is for the 1st floor our our house in South Eastern MA (about 6 miles from the ocean). Thanks

- Check those pages out and see if this helps. I'm sure that since your 6 miles away the hardwood will be fine. Always wipe up any moisture from the floor or spills. There are many more positives about hardwood floors than there are negatives. If you have pets get a hard Janka type of hardwood - something 1800 and up. This will be better for maintaining them with your pups nails. I personally think that either way you're choosing the right floor not matter what! :) have a great time with this! there tons more info on that same site for you for free! have fun! SO MANY OPTIONS!

- Q: What does the composite wood floor do?

- Composite wood flooring is a non-standard noun, in any national standards and normative data are not found in the word. Consumers claim that composite wood flooring generally refers to the strengthening of wood flooring (scientific name: impregnated paper laminated wooden floor). It is in the wood after crushing, filling glue, preservatives, additives, hot press high temperature and high pressure suppression treatment, so it broke the physical structure of logs, to overcome the poor stability of the logs. Composite floor of the high strength, uniform specifications, high wear resistance, corrosion, moth and decorative effect, and to overcome the surface of the wood scar, worm, color problems. Composite wood flooring without paint waxing, the use of a wide range, easy to care, is the most suitable for modern family life rhythm of the ground material. In addition, the composite floor of the wood use rate is high, is a good environmental materials.

- Q: The use of composite flooring for a long time, a little dirty, dark, in the supermarket in the sea over the fall of the name of the law, but the feeling of no effect, there is no other better way to clean the complex cleaning floor. The composite floor color itself is a little light, so a dirty, to see the special clear. Thank you heroes Weapon. More

- Buy the perfect product cleaning detergent easy to clean.

- Q: Will the floor of the floor be poisonous?

- Composite wood flooring environmental standards, but there really do this harm. Composite wood flooring is usually 3 layers, 5 layers or more. Usually solid wood multi-layer composite, as well as non-solid wood multi-layer composite. Layer between the use of glue bonding. To warm the ground will promote the glue and woodworking boards and other artificial wood in the distribution of harmful substances. So if the home to consider the warm, it is best to use three layers of solid wood flooring, less glue content, solid wood does not exist harm.

- Q: Composite floor with formaldehyde? Which brand of composite floor is not a full

- There is no formaldehyde without strengthening the composite floor of the peak of the risk of consumption of the rudder with the fine penalty. You can only choose large-scale, responsible brand. The so-called E0 level, the European standard is less than or equal to 0.3 mg / L release; in China, not called E0, called EO (European), the standard is less than or equal to 0.5 mg / L release. At present, the release of the composite flooring, there is only theoretically possible.

- Q: How to identify the quality of composite flooring?

- First, the color of paper, look at the surface of the color is naturally not really second, wear-resistant layer, to see the surface of the wear resistance, the state to achieve more than 4500 turn can be used in the family, the general manufacturers have reached more than 6000 rpm Third, the environmental protection level traces of Cao Ke 丨 long check Hsue magic, is the release of formaldehyde

- Q: Home with wooden floor or tiles good?

- It depends on whether you like tiles or wood flooring. I suggest you bedroom and study with wooden floor, living room aisle kitchen bathroom tiles. Wood flooring as far as possible with solid wood, so more durable. Also, how will the wood floor crack? How's this question? I have never heard of the wooden floor cracked, often heard only complained that the floor mustor up the quality of the bad ah so that the quality of solid wood flooring certainly no problem, that is, when installed, pay attention to the ground to leveling.

- Q: Home immediately to decoration, and now has been considering the use of solid wood flooring or laminate flooring good? Look at the wood composite floor, wood flooring is not a wooden board, do not know what kind of money is more affordable, but also moisture, long service life? It is a fog! Please give me advice under more

- Solid wood flooring structure is three or more than three layers of thin wood bonded together, strengthen the floor is made of wood and materials from the beating press, from the price point of view, strengthen the floor than the solid wood flooring cheaper. From the environmental point of view, the floor in the bonding process, need to use glue. The quality of the glue used by the manufacturers is not the same. Adhesive contains formaldehyde, strengthen the use of plastic glue on the floor, if the high content of formaldehyde in the plastic, does not meet the national evaluation criteria, it is bound to the high content of formaldehyde, the skeleton of the frozen meat, , Affecting family life health. And solid wood composite floor with less glue, so, relatively speaking, low formaldehyde content, the quality is more environmentally friendly. If you choose the international environmental quality of the floor, then the problem of formaldehyde do not have to worry too much, strengthen the floor is also a good choice, after all, to strengthen the floor easier to manage, and cheap, suitable for mass consumption. From the comfort point of view, solid wood flooring foot feel due to strengthen the floor.

Send your message to us

Plastic Decks/Green BuildingWood Plastic

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords