Quick Details

Place of Origin: Liaoning, China (Mainland)

Brand Name: CMAX

Application: Steel Making

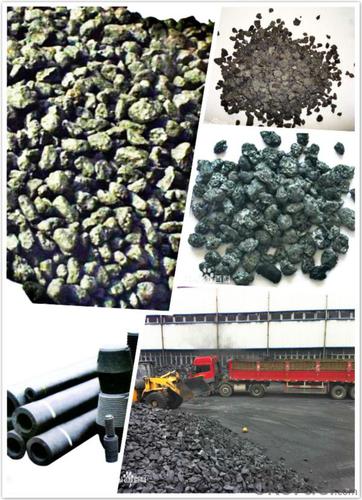

Shape: Carbon Powder

Dimensions: 0-1MM 90%, 1-3MM 90%, 1-5MM 90%, 2-8MM 90%

Product Type: Carbon Additive

C Content (%): 98.5%min, 99%min

S Content (%): 0.5%max, 0.7%max

Ash Content (%): 0.5%max, 0.8%max

Volatile: 0.5%max, 0.8%max

Moisture: 0.5% MAX

Item Name: Petroleum Coke Type Calcined Petroleum Coke