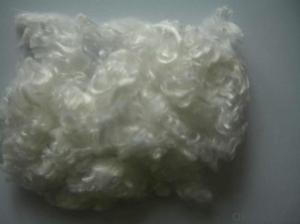

PET Staple Fiber, Hollow or Solid for Spinning

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Polyester Fiber

Material: 100% Polyester

Fiber Type: Staple

Pattern: Raw

Style: Solid

Grade: Recycled

Feature: Anti-Static, siliconized

Color:as per request

Fiber Length: 32mm-102mm

Fineness: 1.2D-18D

Package of Polyester Staple Fiber:

Packed by bale.

250kg pressed bale

Qtty/20'fcl: 38 bales/9.5mt

Qtty/40'HQ: 75 bales or 96 bales/22mt

Application of Polyester Staple Fiber:

Polyester Staple Fiber is widely used for spinning, nonwoven, carpet, wadding etc.

.FAQ

Here is several common questions we prepared which may help you to know us well:

1>Introduction of the company?

we focus on the production of PET staple fiber,. have been exporting this product to overseas market for many years. Customized product is also available based on your detailed requirements. We'd like to give you full support to promote our cooperation and looking forward to your kind enquiry.

2> Is customized product available?

Yes, different specification could be made as per your kind request.

3>What's minium order quantity and can we have a container of several different specifications?

Normally we suggest you a full container load as moq as the price would be the best with full container. Of course , several specification for one container is ok if each specification is availbale.

- Q: Why does the short sleeved sportswear of polyester fiber stick to the body?

- Polyester fiber fabrics (polyester fibre) synthetic fiber polyester by organic acid and diol which is prepared by spinning the. Polyester chain research report pointed out: industrialization, a large number of polyester fiber is made from polyethylene terephthalate, China's product called polyester. It is the largest variety of synthetic fiber at present.

- Q: What are the different effects of mascara and fiber?

- Mascara can make your eyelashes look longer, visually enhance the delicate eyelashes, but also make your eyes look particularly divine.

- Q: The difference between polyester and hollow fiber

- The difference is whether there is a hole in the center of the cross section of the fiber.

- Q: What's the acid and alkaline difference between wool and cellulose fiber?

- The acid and alkali properties of the two are just the oppositeYou also want how many original, ask questions, one hundred times will not copy, copy others, don't believe, then ask!

- Q: Compared with the traditional reinforcement technology, the reinforcement effect of CFRP sheets is different from the traditional reinforcement technology What's the price of carbon fiber reinforcement?

- The carbon fiber reinforcement strength mainly depends on carbon fiber reinforcement drawings, drawings of carbon fiber reinforced high strength, the carbon fiber reinforced the price of intangible higher, the price will be appropriate to lower prices is carbon fiber reinforcement and a factor of carbon fiber reinforcement area and reinforcement strength is not how much high carbon fiber, carbon fiber reinforced carbon fiber reinforced area so the price will be cheaper, the price will be high price and amount of reinforcement of carbon fiber reinforced carbon fiber is not great

- Q: Structural performance difference between polyacrylonitrile and carbon fiber

- Carbon fibers are formed by pre oxidation and carbonization of polyacrylonitrile.

- Q: What fabric is sticky fiber?

- There is no adhesive fiber in textiles, which is only viscose.

- Q: Which material is expensive, chiffon or polyester?

- Your question is not clear because you do not understand the relation between the textile material and the fabric.First of all, a fabric, chiffon just refers to Georgette, weft is a thin and strong twist fabric. Chiffon can be made from pure silk or polyester (polyester). Daqing tree original reply

- Q: Why has the fabric of bamboo fiber shrunk so much?

- Bamboo fiber cross section is full of large and small oval pores, can absorb a lot of moisture in a moment, the volume will expand, cool dry because of its fiber characteristics will shrink.

- Q: Comparison of bamboo fiber reinforced flooring with wood fiber reinforced flooring

- Laminate flooring commonly known as "Diamond Board", the standard name for "impregnated paper laminated wooden floor."". Laminate flooring is generally composed of four layers of material, namely, wear-resistant layer, decorative layer, high-density base material layer, balance (moisture-proof) layer. The qualified laminate flooring is made of one or more layers of impregnating thermosetting amino resins. It is covered with high density board and other base material. The back is balanced with damp proof layer, and the front is added with decorative layer and wear-resisting layer.

Send your message to us

PET Staple Fiber, Hollow or Solid for Spinning

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches