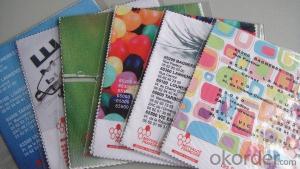

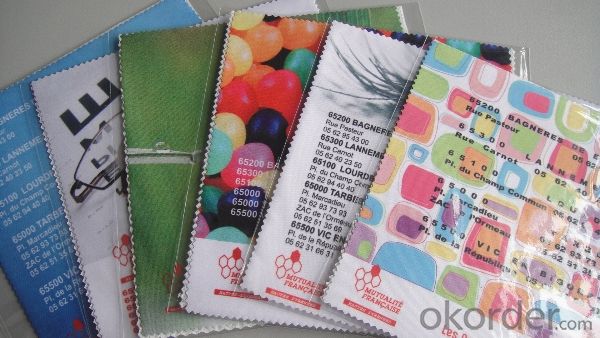

Glasses cleaning cloth with company informations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

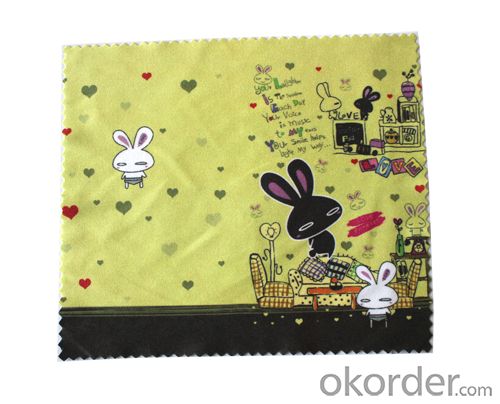

Specifications of glasses cleaning colth

1.glasses cleaning cloth,microfiber glasses cleaning

2.any size /color is available

3.customized logo

4.polyester&polymide

We manufacture all kinds of microfiber to cleaning cloth,eyeglasses pouch ,polishing cloth ,jewellery bag and so on.

We can customize any product according to your requirements, any size, color, package, qualities, printing is available.

Specialized and experienced, we have engaged in making microfiber products for over 10 years.

Over 5 quality inspectors each department, we have great control on quality aiming at offering you the best goods.

Material 80%polyester+20polyamide / 100%polyester

Size 5*3,5*7,6*8,8*10etc (any size is available)

Printing Digital print, silk print, etc (can print customer logo with Pantone colour)

Colour White, black, orange, yellow, grey, blue, green. Etc (can dye cloth with Pantone colour)

Edge Saw edge, round edge, straight edge, cut cloth into egg shape, etc

Gram weight:(gms)t 180-230gsm

Package 1. 100 pcs each in a polybag 2. each in a polybag 3. individual pvc(vinyl) pouch

MOQ 3,000 pcs (available colors in stock), 20,000 pcs (customized color)

Imprint Silkscreen,digital printing(heat tranfer ptinting),hot stamp,embroidery

Packing

1.bulk packing:100pcs per opp bag 2. individual packing: each in a opp/vinlye bag

- Q: Is bamboo charcoal fiber polyester?

- There are not more than 15% bamboo charcoal fibers added in the market.Businessmen generally write "polyester fiber (including bamboo charcoal fiber)", but the proportion of bamboo charcoal fiber is unknown, said it may contain 99%, but if only 0.01%, this is also true.

- Q: What is the density of polyester?

- Poly (ethylene terephthalate) is prepared by esterification of terephthalic acid two methyl ester with ethylene glycol ester or esterification of terephthalic acid with ethylene glycol. The average molecular weight (2-3) x 104 of the crystalline saturated polyester is 1.5-1.8. The average molecular weight is equal to the molecular weight. The relative density is 1.368., the melting point is 225 DEG C, the flow temperature is 243 DEG C: the glass transition temperature is 80 DEG C, Martin is heat-resistant 80 DEG C, the thermal deformation temperature is 98 DEG C (1. 82MPa), and the decomposition temperature is 353 DEG C. With good mechanical properties, high rigidity, high hardness, low water absorption and good dimensional stability. Good toughness, impact resistance, friction resistance and creep resistance. Good chemical resistance, soluble in cresol, concentrated sulfuric acid, nitrobenzene, three chloroacetic acid, chlorophenol, insoluble in methanol, ethanol, acetone, alkane. Use temperature -100 ~ 120 degrees centigrade.

- Q: How do you recognize the wool of a sweater?

- First of all, the texture of the wool fabricWool, rabbit hair, camel hair, wool type chemical fiber as the main raw material of the fabric, usually with wool for the living, it is the year of high-grade fabric, good elasticity, anti wrinkle, stiff, durable wear-resistant, strong warm, comfortable and beautiful, pure color and other advantages, the price is also the most expensiveBut now there are a lot of chemical fiber fabric sweater, with its fastness, good elasticity, stiffness, abrasion resistant washing, easy storage and loved by the people. Purified fabrics are fabrics made from pure chemical fibers. Its properties are determined by the properties of the chemical fibres themselves. Chemical fiber can be processed according to different requirements into a certain length, and woven into imitation silk, Imitation cotton, imitation linen, elastic imitation wool, medium length imitation wool fabric according to different requirements, and its price is also the cheapest

- Q: What is a review of fiber anti cracking agent?

- 1, double protection, double effect. It contains two kinds of anti swelling components, such as micro expansion agent and synthetic fiber, which can improve the anti cracking ability of concrete from two aspects of physics and chemistry, and provide double protection for concrete.2, special water retention components, improve maintenance efficiency. The unique water retention component can prevent evaporation of water at the early stage of hydration. As the hydration proceeds, the water is released, thereby improving the maintenance efficiency.

- Q: What is blended spinning fabric?

- Blended fabric is cotton, chemical fiber and other silk, hemp textile products of natural fiber blended yarn fabric. For example: polyester cotton, polyester wool gabardine etc..

- Q: Is Chiffon the same as polyester?

- If prices are concerned, polyester Chiffon should be cheaper. The fruiting of polyesters. I hope I can help you.

- Q: What is the accuracy of the hollow fiber and the ceramic filter core of the filter?

- The filtration accuracy of the hollow fiber membrane is 0.01 microns, and the filtered water can intercept most of the bacteria and viruses, and the purification effect is only second to the reverse osmosis membrane. Ceramic filter accuracy to see the quality of ceramics.

- Q: What's the difference between natural fiber and chemical fiber?

- Natural fiber is a natural fiber that can be obtained directly. Natural fiber can be divided into plant fiber, animal fiber and mineral fiber three kinds.1., plant fiber, plant fiber, also known as natural cellulose fiber, is the plant seeds, fruits, stems, leaves and other places to obtain fiber. It includes seed fiber, phloem fiber and leaf fiber.The seed fiber such as cotton, kapok etc.;The bast fiber such as ramie, flax and jute, kenaf and Apocynum etc;The leaves of sisal, Abaca fiber, such as.2. animal fiber, also known as natural protein fiber, is obtained from the hair of animals or the gland secretions of insects. It contains hair and glandular secretions.The hair: wool, cashmere, camel hair, yak hair, etc.;The gland secretion: Sang silk, tussah silk, silk, silk and other cassava castor.3. mineral fibers, mineral fibers, also known as natural inorganic fibers, are fibers extracted from minerals. Mainly including asbestos.

- Q: Fiber cotton, doll cotton, sponge difference

- Doll cotton: different specifications of three-dimensional polyester staple fiber by fully carding, so that it can maintain enough elasticity. High degree of bulkiness, light and soft, long set, will not deform.

- Q: What is the difference between regenerated fibers and Lesel fibers?

- The development of regenerated cellulose fiber can be divided into three stages on the whole, forming the three generation products. The first generation was the ordinary viscose fiber, which was released in the early twentieth Century to solve the cotton shortage. The second generation was started in 1950s to realize industrialized production of high wet modulus viscose fiber, its main products include Japan R & D toramomen (named Polynosic) and the change of American R & D high wet modulus fiber HWM and Lenzing Co in late 80s by the new process of production of Modal fiber. In late 60s, due to the rapid development of synthetic fiber production technology, low cost and adequate sources of raw materials, synthetic fibers have greatly affected the market position of regenerated cellulose fiber. Many research institutions and enterprises to pay more attention to the development and application of new synthetic fiber. During this period, the development of regenerated cellulose fibers in the world tended to be stagnant. Third generation products are introduced in 1990s staple fiber Tencel (Tencel), filament Newcell as a representative. Influenced by the awareness of health and environmental protection, nature and other factors, people have a new understanding of the physicochemical properties of regenerated cellulose fiber, a new generation of regenerated cellulose fibers has been fully improved, therefore, the application of regenerated cellulose fibers of the re emergence of rapid development.

Send your message to us

Glasses cleaning cloth with company informations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords