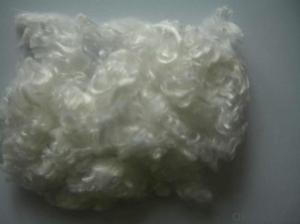

Polyester Staple Fiber used for Spinning

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of 100% Polyester Staple Fiber used for Carpet:

Fineness: 1.2D-2.5D

Fiber Length: 38-51mm

Normal specifications: 1.4D*38mm, 1.4D*51mm, 1.5D*38m

Material:100% polyester

Features of 100% Polyester Staple Fiber used for Carpet:

1) Material: 100% Polyester.

2) Color: according to your requirement

3) Prices: have good competitive advantage

4) Delivery time: 15 days after the receipt of deposit

5) Payment: T/T,L/C

Usage of 100% Polyester Staple Fiber used for Carpet:

stuffing and packing of toy,pillow,sofa,seatcushion and leaning cushion;thermalinsulation lining of shoes,gloves,cap and garment and so on;raw material of spray finishing cotton,gel-free cotton,hardening cotton and non wovens;

- Q: What is the density of polyester?

- Polyester fiber is an important variety of synthetic fiber, and it is the commodity name of polyester fiber in our country. It is a pure terephthalic acid (PTA) or terephthalic acid methyl ester two (DMT) and ethylene glycol (EG) as a fiber polymer, polyethylene terephthalate as raw materials by esterification or transesterification and polycondensation prepared (PET), the spinning and postprocessing fibers.

- Q: How to make fiber streamline test for forging parts?

- With 1:1 hydrochloric acid water heating, not necessarily boil, about 75 degrees can be, in acid solution for 25-20 minutes. Then take out and rinse with alcohol. Use a magnifying glass that is no more than 100 times larger. Only the streamline of the forging is clear, the direction of the inclusion in the forging process of the metal is the direction of the streamline

- Q: Why are the moisture absorption capacity of viscose fiber and hemp larger than that of cotton, and the moisture absorption capacity of synthetic fiber is lower than that of natural fiber and maturity

- The moisture absorption capacity of synthetic fibers is lower than that of natural fibers, mainly due to the small amount of crevice in synthetic fibers;Cotton fiber with poor maturity is more hygroscopic than mature cotton fiber, mainly due to the larger specific surface area of cotton fiber with poor maturity

- Q: Which material is good, cotton blended or synthetic?

- From the material, cotton (natural fiber best), blending, followed by the poor purification of fiber.But there are a variety of fabric style and function of all kinds of fabrics, from dress up, suggest or with cotton and other natural fiber, natural fiber from the nature, with good skin, comfortable; chemical fiber fabrics from raw materials are synthetic, wearing skin, sweat less, but wear solid, etc., can be processed to form many kinds of clothes.

- Q: Does Vic fiber belong to admixture?

- To answer is not belong to Vic fiber (concrete) admixture, I think we must first look at what is called (concrete) admixture: concrete admixture is added in concrete mixing before or during mix, in order to improve the new concrete mixing and (or) the properties of hardened concrete materials, can also be referred to as additive.

- Q: What is plastic fiber?

- In plastic fiber, moisture detection is very important. It can be measured by SFY-100 plastic moisture content tester. It is quick, convenient and easy to operate,The definition of plastic (United States plastics industry association) - all or part of the carbon and oxygen, hydrogen, nitrogen and other organic and inorganic elements combined into a solid, at the final stage of manufacture, in the manufacture of some stage is liquid, which can heat or pressure, or two and by the way, the the formation of various shapes, this huge and any kind of material in the race, be the most changeful, can be called the plastic.

- Q: What material is bamboo fiber?

- Bamboo fiber is a kind of cellulose fiber extracted from natural bamboo. It is the fifth natural fiber after cotton, hemp, wool and silk. Bamboo fiber has the characteristics of good air permeability, instant water absorption, strong abrasion resistance and good dyeing property. Meanwhile, it has the functions of natural antibacterial, bacteriostasis, mite removal, deodorization and anti ultraviolet. Experts point out that bamboo fiber is a kind of natural environmental friendly green fiber in the true sense

- Q: How about the fabric panties of bamboo fiber?

- Bamboo fiber is a kind of cellulose fiber extracted from natural bamboo. It is the fifth natural fiber after cotton, hemp, wool and silk.Bamboo fiber has the characteristics of good air permeability, instant water absorption, strong abrasion resistance and good dyeing property. Meanwhile, it has the functions of natural antibacterial, bacteriostasis, mite removal, deodorization and anti ultraviolet. Bamboo fiber is a kind of natural environmental friendly green fiber in real sense. The bamboo fiber textile completely replicates the natural characteristics of the bamboo fiber.Buy a high content of bamboo fiber, so that it is comfortable to wear, washing to use medium washing liquid.

- Q: What is the environmental protection rating of MDF?

- According to the national standard, MDF according to its free formaldehyde content can be divided into E0 class, E1 class, E2 class. E2 formaldehyde emission is less than or equal to 5mg/L; E1 formaldehyde emission is less than or equal to 1.5mg/L, can be directly used for indoor decoration; formaldehyde emission is less than or equal to E0 0.5mg/L. Consumers in the purchase of MDF, should try to buy formaldehyde emission goods, such products are more secure

- Q: What is the working temperature of the carbon fiber material in the mechanical structure?

- Synthetic stone (carbon fiber board) is a kind of composite material made of glass fiber and antistatic high mechanical strength resin. A ring that gradually rises in temperatureThe ability to continue to maintain its physical properties in the environment so that it can achieve high standard results during peak soldering without distortion. High temperature nanocomposite materials (synthetic stones) are not separated from the substrate in a harsh environment for a short period of time at 350 DEG C and operating temperatures at temperatures of 260 DEG C. Synthetic stone can improve the quality of PCBA in wave soldering process, avoiding the pollution of gold finger or contact hole because of human touch.

Send your message to us

Polyester Staple Fiber used for Spinning

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords