PE Woven Tarpaulin with 2x3m, 3x4m,3x5m, 4x5m,

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 1200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description for Tarpaulin

Materials:PP or PE

Regular size: 2x3m, 3x4m,3x5m, 4x5m, 4x6m, 5x8m, 6x8m, 6x10m, 2.5x3.6m, 3.6x5.4m, 5.4x7.2m, 7.2x9m, 10x50m. According to the requirements of customers....,

Mesh: 9x9 to 14x14

Width: 1.6 to 12m

Weight: 70 to 360gsm

Denier: 500D ~ 1500D

Color: various colors available

Length: no limit

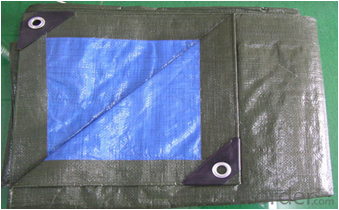

Water, mildew and tear resistant, Double waterproof surfaces.Reinforced corner;

Rope in along edges for added strength,

For recreational vehicles, trucks, boats, construction sites, firewood.

Multi-purpose: truck cover, trailer cover, equipment cover, ground cover, emergency shelter, painting tarp, trailer awning, etc.

2. Fetures and Application:

sun-resistant,UV treated, lightweight, easy to fold, durable and other characteristics.

Tarpaulin is widely used for truck canopy,ship cover and cargo storage or transportation in mineral factories and ports, also can be used as tents in outside travel and calamities.The tarpaulin is to cover and protect the goods in the open air and avoid the goods get wet.

3. Specifications for Tarpaulin

Product | |

Material | PP or PE (Inner HDPE Woven Fabric, LDPE laminated both sides ) |

Weight | 55 GSM / SQ.M ~ 300 GSM / SQ.M |

Width | 2 meter or 4 meter withou joint. Available for wider fabric by heat sealing. Or as the client's requirment |

Denier | 500 ~ 3000 Denier |

Lenght | 50 meter to 200 meter |

Density / sq.inch : | 7X6, 7X7, 8X7, 8X8, 10X8, 10X10, 12X12, 14X14, 16X16 ( 2x3m, 3x4m,3x5m, 4x5m, 4x6m, 5x8m, 6x8m, 6x10m, 2.5x3.6m, 3.6x5.4m, 5.4x7.2m, 7.2x9m, 10x50m.) |

Mesh | 8x8 9x9 10x10 11x11 12x12 14x14 |

Making | a. All edges with PP rope in hem; |

Package | Roll-up Tarp | Packed On Paper Tubes & |

Bale packing | A eyelet every 3 feet(about 1m) or customer-made, with four edges heat-sealed by pp rope in hem and four corners by black triangle. | |

Special treatment | Fire Resardant/Ultra Violet Protection, Frame Retardant treatment available upon request | |

Feature | Different sizes and colors are available | |

Multi-purpose | For recreational vehicles, trucks, boats, cargo protection, construction sites, firewood, truck cover, trailer cover, equipment cover, ground cover, emergency shelter, painting tarp, trailer awning, agriculture, garden, camping etc. | |

Color | Green, White, Blue, Silver , Blue White, Blue Silver,Blue Orange etc., any colors as the client's requirments | |

Delivery time | Within 25 days after receiving the prepayment | |

Other | Logos or other company information could be printed on tarpaulin. | |

4. Photo for Tarpaulin

- Q: Do you need a cushion on the ground floor?

- In addition to wood also buy wooden side, used as the main beam, beam and pillars. The ground is also recommended to raise, raise the place also to beam and pillars The number of boards to be based on your design to determine the ground practice, roof practices will affect the number of wood

- Q: Can the cushion on the prefabricated board floor be dug?

- Prefabricated board floor layer of cement layer is not called the cushion, should be called leveling layer, this layer can be removed, but be careful not to damage the prefabricated plate.

- Q: Is it possible to make a waterproof layer

- 3, waterproof layer set and standard construction methods: to be painted 2 to 3 times, or should be added fiberglass cloth, and each brushing the thickness of the cured material shall not be less than 1 mm, and should be completely dry (about 5 -8 hours) and then the next construction. After brushing, but also in the paint waterproof layer to do a mortar protective layer, and finally paste the tile.

- Q: Is the raft cushion waterproofing full of the cushion?

- The request is full. Raft foundation do not do waterproof mainly depends on the design of the groundwater level considerations, calculated if the floor itself to meet the requirements, you can not do, and not rigid to do.

- Q: What is the difference between leveling and cushion?

- Cushion is generally used in the ground floor of the building, leveling layer is generally used in the floor or roof. According to the above analysis, I believe that we use the quota, where the floor, roof construction, it should be used to find the level of the fixed sub-head, because there is no so-called concept of the cushion, leveling layer thickness is not what Specific provisions can also be used at the same time different layers of leveling, but must be carried out in accordance with the design requirements, so as not to exceed the load;

- Q: Cushion, waterproof layer construction to do what information

- 4, waterproof layer set and standard construction methods: to be painted 2 to 3 times, or should be added fiberglass cloth, and each brushing the thickness of the cured material shall not be less than 1 mm, and should be completely dry (about 5 -8 hours) and then the next construction. After brushing, but also in the paint waterproof layer to do a mortar protective layer, and finally paste the tile.

- Q: What is the relationship between the cushion and the ring beam?

- There is no direct relationship between the cushion and the ring beam.

- Q: Is foam concrete suitable for use as a cushion?

- Inappropriate. Bubble concrete is a new type of energy-saving and environmentally friendly building materials, which are widely used in wall materials, but there are still some defects, such as low strength, cracking, water absorption, as the cushion of its strength is not enough standard.

- Q: Large area ground concrete cushion seam Why is the separation of joints generally concrete

- hird, the relevant parts Different types of rigid waterproof layer separation spacing in addition to meet the calculation needs, but also in the following parts set sub-grid joints. 1. The deformation of the roof structure sensitive parts; 2. Roof and roof drainage direction changes; 3. The junction of the waterproofing layer and the protruding roof structure; 4. Under normal circumstances, each bay load-bearing walls should be set sub-grid seam. 5. Between the waterproof layer and the load-bearing or non-load-bearing parapet or gable should be set sub-grid joints, and in the node structure for proper treatment.

- Q: How to build a fine stone concrete cushion?

- The main role of the cushion is to meet the requirements of the design elevation. In addition, the cushion to meet the sound insulation, insulation, insulation, slope and buried pipeline and other functional requirements and set a variety of levels.

Send your message to us

PE Woven Tarpaulin with 2x3m, 3x4m,3x5m, 4x5m,

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 1200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches