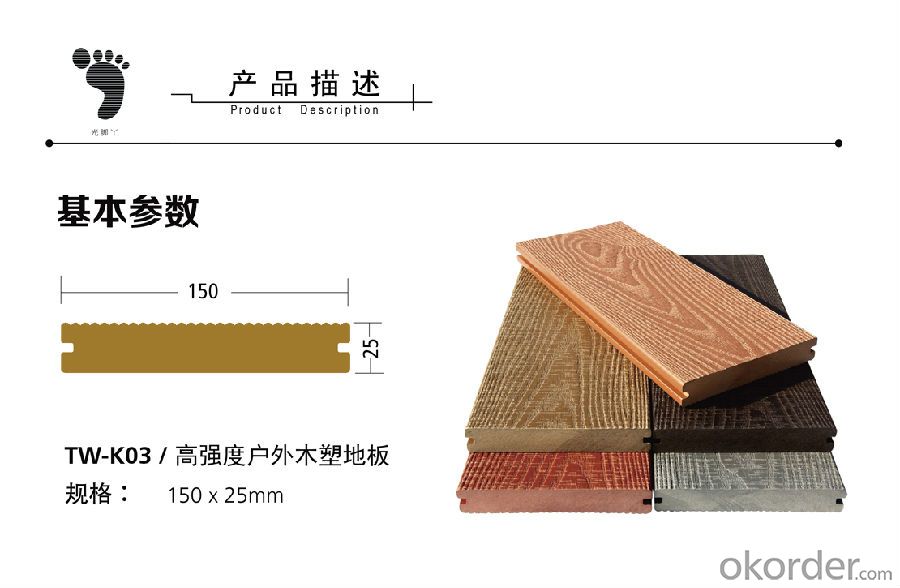

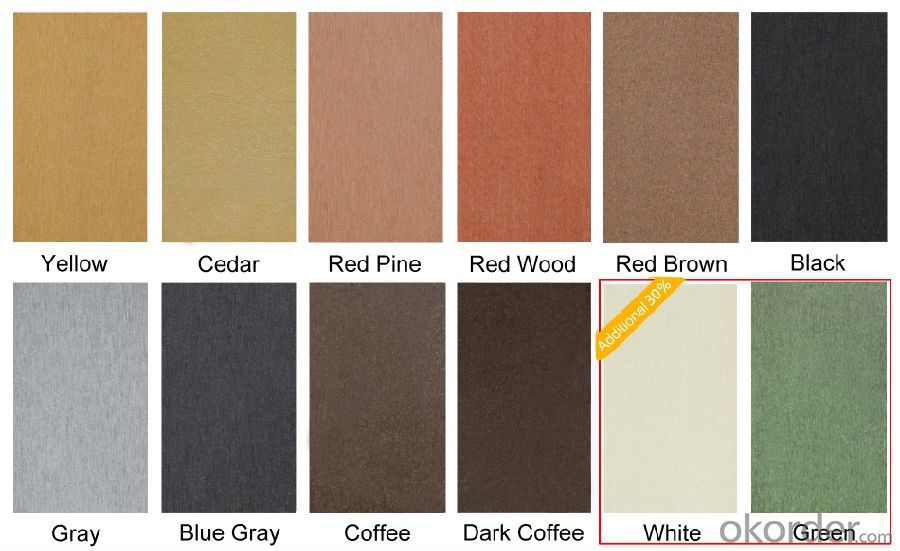

Outdoor wood plastic floor (wood plastic composite)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product structure description:

Barefoot wood plastic is a combination of natural wood fiber and eco-friendly plastic polymer. It is a composite material. The manufacturing process is wood powder plastic and the required coupling agent and additives. It is fully mixed under high temperature and high pressure. Extruder extrusion is cooled. The barefoot control of the raw materials is extremely strict. The raw material of the wood fiber in the product is 80 mesh aspen wood powder is uniform and fine; the plastic polymer uses high density polyethylene; the US DuPont import auxiliaries; the first-class raw materials for the future The mechanical properties of the formed product provide a strong guarantee to ensure the stability of the product.

Main features of the product:

1. Strong bending strength (compressive ability) and high weather resistance:

We insist on the use of high quality HDPE (High Density Polyethylene), which has higher crystallinity than ordinary plastics on the market (low density, medium density) and thus exhibits higher strength. The process of rotation from the molten state to the solid state takes some time to eventually form crystals. HDPE undergoing this process will achieve higher shrinkage, 2-3 times the tensile strength of LDPE (low density polyethylene) and a compressive strength of 4600 psi. At the same time it has good heat resistance and cold resistance.

Weather resistance: good performance from minus 40 degrees to over 60 degrees

2, waterproof and moisture resistance:

3. Photooxidation and fading (anti-fading);

4. Effectively prevent oxidation and breakage, and have a long service life;

5, effective slip resistance;

6, no need to paint maintenance costs are low:

Get competitive prices from our large capacity. At the same time, the large capacity of the factory can be delivered quickly.

. No formaldehyde or harmful substances.

. Environmentally friendly products, the government vigorously promoted.

- Q: Will the composite floor be faded for a long time?

- Will the composite floor be faded for a long time?

- Q: Manufacturers said that the composite wood floor is not on the glue, but the information on the Internet that must be on the glue, ask the question: 1 must be on the edge of Gong Chi folder Jurassic grass Wei Wei even? 2 what is 3d glue? How to identify good and fake glue? What brand is better? 3, the scene how to monitor the glue is full? More

- Composite wood flooring installation, only the local brush glue, no full coating

- Q: Solid wood composite floor suitable for installation to warm it?

- Solid wood composite floor suitable for installation to warm it?

- Q: What you mean by Engineered flooring? What is the benificts of Engineered flooring?

- Engineered wood is an all wood product made of several plys of wood criss crossed for strength just as ply wood is. Its usually made of three plys but I ve seen cheaper stuff with as many as 5 plys. Its a thinner wood ( 3/8ths inch thick on average but you can get thinner and thicker) It s made for places where thickness is an issue and you can t use the standard 3/4 solid wood. Its more versatile in installation . than standard wood. Its made to be glued, nailed ( stapled actually) and made to float in special applications. In certain applications it can be used below grade ( certain applications mind you) . The wood is made to strict milling so it goes together easy and is very DIY er friendly. Any questions you can e mail me through my avatar. GL

- Q: Just renovated soon, the bottom of the plumbing. Now the corner of the solid wood composite floor darkened, and little by little bigger. It is water and water leakage, but the pressure of the boiler has not changed.

- Is not it warmly used? In general, such a situation is to warm the cement leveling inside the water in the case of warm heating to lead to the floor black. And then decorate the floor before the floor to open the floor to open the ground and then shop the floor.

- Q: How does the composite floor be polished?

- The composite flooring does not need to be polished.

- Q: Now there are a variety of composite flooring on the market price is basically between 50-70 (popular type) slightly better than 100 points but I would like to ask you who can tell me how to see the floor of the good or bad floor is what What kind of poor quality, please guide the floor and what are the specifications of what kind of suitable for more heat

- How to buy solid wood flooring First, look at the structure: solid wood flooring to multi-layer vertical and horizontal superposition, layers to contain the structure of the form is better, this structure not only has a better sense of foot, but also to overcome the deformation of the floor, high Quality of the three-tier parquet can even be done without deformation. Second, look at the origin of the carved Chi Chi fainting agent Petite touch floor: solid wood flooring quality is good or bad mainly to see the surface of the hardwood layer of tree species and age, due to Southeast Asia and South America along with more primeval forests, relatively high quality wood, the production of solid wood The quality of the composite flooring is relatively high and the cost is low. At present, Thailand, Indonesia has become the world's three solid wood flooring the main origin. Third, look at the surface thickness: high-quality solid wood flooring surface thickness of up to 4mm. Visual texture strong, rich color; foot feel better, comfortable walking; can also be repeated renovation, long-term use. Fourth, look at the brand: As the solid wood flooring prices higher, so after-sales service, especially after installation and installation of the maintenance is more important, it requires a certain strength of the brand floor company to provide professional installation and long-term maintenance guarantee, these general small The company is hard to do.

- Q: Solid wood flooring is not easy to scratches?

- Multilayer solid wood and solid wood flooring test wear resistance method and strengthen the floor is different. Multi-layer solid wood paint quality is measured by the loss of paint film, that is, with 180 mesh grinding wheel, weight 500g and the film surface relative friction, the national standard paint mill loss of ≤ 0.08g / 100r, so When you buy, you can place the floor board oblique light, from the end of the board to observe whether the film is uniform and full, with or without wavy indentation and so on. High-quality solid wood composite flooring surface coating more uniform. You in the course of the use of scratches, there may be in the course of your carelessly scratched by other sharp objects, or the floor of the paint itself did not do? If that is the case, you are looking for manufacturers. Also give you some way to deal with scratches: 1 If the surface of the paint film is not bad, just a little mark, after cleaning, polished wax can be used directly polished. If the floor paint film damaged or exposed white, can be used No. 400 water sandpaper dipped in soap and water to polish, and then the chicken feast of the darffs of the immortal clever, to be dry, the local complement color, color dry, and then brush a paint, After drying for 24 hours, polish with 400 water sandpaper and then wipe the wax for polishing. 2 scratch depth is different, the repair method is also different. The best solution is very shallow scratches, with 0 metal friction can be solved with oil friction. (Very soft metal cotton, without leaving scratches) deep scratches, you need to find a professional to repair. The usual way is to expand the scratch to the appropriate width, putty, and then fill the paint.

- Q: I recently just installed engineered wood click-lock flooring (floating) over plywood subfloor on our second floor and I noticed some hollow or bounce spots near the entry of the room. The subfloor is plywood and it has a layer of foam underlayment on top and then the flooring. Question: to fix this problem, can I just nail some high spots down to the plywood? I really want to avoid redoing the whole room if possible. What are some other options that I have? The subfloor is not perfectly leveled but it is pretty leveled (I sanded them).

- yes you can and that's about all you can do. make sure you use finish nails, I use ringshanks, (paneling nails) and drive them in between the joints to hide them. p.s. you don't really have options now. leveling is top priority, now that's too late, however, they all have some high spots, I don't install them anymore, I hate them.

- Q: What is the price of geothermal reinforced laminate flooring?

- OKorder can be found to see

Send your message to us

Outdoor wood plastic floor (wood plastic composite)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords