WPC outdoor decking floor /Wood-Plastic Composite Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

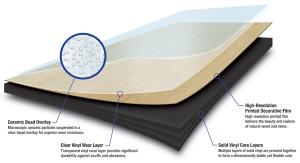

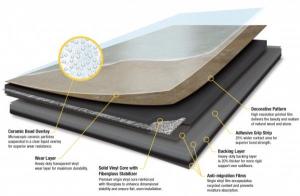

Material | WPC (wood plastic composite) |

Technic | Extruded |

Size | 140x27mm |

Length | 2.2m, 2.9m,and 5.8m or customized |

Accessories | Plastic / stainless steel clips + WPC joist + WPC skirting |

Certificate | CE,SGS,ISO9001,ISO14001 |

Usage | In city construction and environment layout, widely used for outdoor decking floor, Wall panel. railing, fence, bridge, dock,gloriette, gazebo, boardwalk,etc |

Other Available Size | 30x40mm,50x28mm,50x50mm,55x12mm,60x40mm,71x12mm,80x80mm, 88x23mm,96x13mm,96x20mm,100x36mm,100x100mm,105x31mm,120x120mm,132x20mm,135x23mm,140x23mm,140x25mm,140*30mm,140x40mm,145x23m, 146x31mm,150x25mm,150x150mm, 167x22mm,170x25mm,200x50mm,220x12mm,250x15mm,450x20mm |

Color |

|

MOQ | 200 square meters, and can be negotiated for trail order |

Payment Term | T/T,L/C,D/A,D/P,Western Union |

Lead Time | 7-10days for each 20 feet container |

Port | Shanghai Port or other ports if needed |

Advantanges

1.100% recycled, environment friendly, saving forest resources

2.Waterproof,UV resistant, color stability

3.Durable,crack resistant

4.CE,SGS,ISO9001,ISO14001,patent

5.Easy to install and low labor cost

6.Requires no painting, no glue, low maintenance

7. Barefoot friendly, anti-slip,no cracking

8. Weather resistant, suitable from-40 to 60

Project Items Show

Packaging

Selling Units | Multiple of 200 |

Volume per batch | 4 cm3 |

Gross weight per | 4200.0 KG |

Package Type | Depend on your requirements |

Welcome to inquiry,we will provide you best service!

- Q: There is a little water with plastic sheeting can pave the floor?

- Note gapThe first floor and the wall to leave room, in the room, the door and the stairs and other fixed facilities connected to the same, leaving gaps, general length between 0.8 cm -1.0 cm.

- Q: PVC plastic floor maintenance and maintenance, daily cleaning what is a good way?

- Dust or vacuum cleaner. Drag the ground dust onto the ground and dry it

- Q: Plastic floor gap can be used to do plastic glass

- No, glass glue is black and transparent,Plastic floor general welding is another splicing processing, plastic flooring material selection PVC special glue, stairs, wall with adhesive

- Q: Ask how to install plastic floor

- Tools: a knife blade, remove the plastic floor flat at room temperature for at least 24 hours, two on each side of the wall to find the center point, draw the cross center line on the floor, the ground is divided into four areas, and then from the central to the laying of three four, clean the ground, make sure the ground can begin after the laying of four, clean (without gum floor) with a scraper coated plastic tile special adhesive, five (Beijiao floor) tore the floor backing off the paper, starting from the six floor of the center line laying in all directions, each piece of tile must be close to the junction, glued to the ground, to avoid the gap seven, laying to the wall the floor tile cutting required size

- Q: Thick floor leather household PVC floor paper waterproof plastic carpet anti-skid plastic floor glue how to install

- Floor leather referred to as civilian leather, poor quality of materials, can be used for a year, if the furniture and the like in the above pressure will be broken.Plastic floor glue construction (general) 10 per square meter, packaging materials of $40 per square meter, (Professional) construction of 13 yuan per square meter,

- Q: Plastic floor glue how shop, suitable for use at home

- The material is of high wear-resistant floor rubber products, the main types of floor glue is too much, please choose the site of special products, if you are a family choose stone plastic sheet, choose the mall commercial airport pure material, rubber flooring, floor board special dance dance, rubber floor has a high requirement for the quality of the ground, the ground should be flat. No sand, dry ground, ground cracks, no different use requirements, main floor glue fire, anti-skid, environmental protection, easy to clean, variety, fast construction, long service life, our factory production of the special plastic Mio dance floor, if so we can provide samples for reference, to the membrane of different thickness different price you want, our dance floor (dance floor, many kinds of special).

- Q: Have engaged in the PVC floor production or research work of predecessors, I am a college student in the existing fireproof problem research project called the PVC floor, check a lot of information without too much of the harvest hope that senior for guidance

- General hard PVC hardness of 80D, basically can reach UL94V0

- Q: Geothermal home. They said to be placed under the damp film plastic sheeting, the purpose is to better moisture. To 1, in order to better moisture with it if there was cement ground moisture and this layer of plastic sheeting on the cement ground? 2, if the heat insulation effect? So how much harm will the plastic cloth after heating...

- Do you use geothermal, best not to spread under plastic, a heat insulation, the other one is now mostly plastic enough environmental protection, and, when it reaches a certain temperature, the plastic above is adsorbed water, affecting the stability of the floor. If you have to use the floor with insect powder, then after you install the floor maintenance work is more. Buy floor is to buy peace of mind, comfortable floor, a care, long-term use effect.

- Q: PVC plastic floor glue thickness can be used for welding

- Coil and sheet, so there are two kinds of glue:

- Q: Ijiali will be on the floor of the kind of plastic that is connected to a piece of letters, animal patterns, such as the name of what ah

- 3) long-term pressure - bearing capacity of 25 tons / square meters long weight will not bump deformation pressure. With the same life.4) corrosion mothproof, environmentally friendly materials, non-toxic harmless, water does not rot is not bad, not afraid of insects.5 sound insulation and noise reduction - to eliminate the ground noise, create a quiet space.

Send your message to us

WPC outdoor decking floor /Wood-Plastic Composite Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords