Vinyl (PVC) Flooring - Wood Plank

- Loading Port:

- China Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 X 20'GP m²

- Supply Capability:

- 50 X 20'GP Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Vinyl (PVC) Flooring

Vinyl (PVC) Flooring is an affordable option that offers style, durability, and long-lasting performance. When installed correctly over proper subflooring, it is extremely resistant to dents, scratches, and stains. Vinyl is easy to install yourself, and is also simple to clean and maintain. One of the main attractions of vinyl is that it is very durable which makes it great for high-traffic rooms. Another quality of vinyl flooring is that it can be made to resemble the look of other flooring types, like hardwood, stone and ceramic. You can create any style you want with vinyl. Choose black and white checkerboard for a retro feel or choose a natural look for an up-scale, classic approach.

Features of Vinyl (PVC) Flooring

· Incredibly realistic photo replication of natural materials

· Brands that offer 100% vinyl material

· Inherent safety features

· Ease of maintenance

· Excellent selection of sizes, shapes

· Naturally water resistant

· Scratch, stain, dent and scuff resistant

· Cost effective

· Exceptional durability

· More resilient than other hard surface floors

· Amazing aesthetics

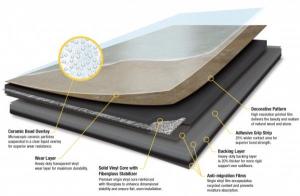

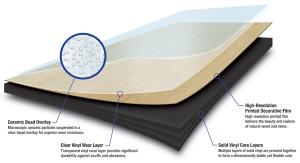

Structure of Vinyl (PVC) Flooring

Specifications of Vinyl (PVC) Flooring

Size: 3" x 36" (76.2 x 914.4mm), 4" x 36" (101.6 x 914.4mm), 6" x 36" (152.4 x 914.4mm), 9" x 36" (228.6 x 914.4mm), 9" x 48" (228.6 x 1219.2mm)

Thickness: 1.5mm, 2.0mm, 2.5mm, 3.0mm

4.0mm, 5.0mm, 6.0mm available for Click System

Wear Layer: 0.1mm, 0.2mm, 0.3mm, 0.5mm, 0.7mm

Technical Specifiations of Vinyl (PVC) Flooring

Characteristic | Standard | Test Result |

Resistance to chemicals | DIN EN423:93 | Class O |

Bearing a castor chair | DIN EN425:94 | No obvious damage |

Dimension | DIN EN427:94 | ±0.1mm(side length<200mm) ±0.25mm(side length>200mm) |

Squareness and straightness | DIN EN427:94 | ≤0.15mm(side length<400mm) ≤0.2mm(side length>400mm) |

Thickness-overall | DIN EN428:93 | ±0.10mm |

Thickness-wearlayer | DIN EN429:93 | ±0.01mm |

Mass per unit area | DIN EN430:94 | pass |

Peeling strength of layers | DIN EN431:94 | >1.8kn/m |

Residual indentation after static load | DIN EN433:94 | ≤0.05mm |

Dimensional stability and curling after exposure to heat | DIN EN434:94 | Shrinkage rate≤0.15% Curling≤1.0mm |

Flexibility | DIN EN435:94 | pass |

Abrasion Resistance | DIN EN660-1:99 | <0.068mm |

Color fastness to light | DIN EN20105-B02 | ≥Crade 6 |

Flammability | DIN EN71-2 | pass |

Toxic element test | DIN EN71-3 | pass |

Specific gravity | ASTM D792:91 | pass |

Fungus Test | ASTM G21:96 | Grade 1 |

- Q: Wood floor plastic liner on the above or below

- It doesn't matter which side of the plastic pad, mainly in the role of the buffer between the wood floor and the ground

- Q: What are the hazards of plastic floor

- Floor leather containing lead compounds, in the use of the process, with the floor leather wear, lead content continues to spread, the formation of lead dust in the air, easy access to infants and young children.

- Q: With this plastic floor mat bed can not? Will not have any impact on people

- This is used in conjunction with the infant floor, which belongs to (XPS) extruded plate and the like, the density is better. Better than foam board (EPS) slightly better, it is best not to shop on the bed as well......

- Q: Spread a layer of plastic cloth under the wooden floor

- A plastic cloth can be laid under the wooden floor.Moistureproof layer, a layer of felt or plastic film, the ground will be able to cut off the water vapor condensed, and let it pass around the foot of a wall left side seam, emitted into the air. Moisture proof material integrity, damage or joints should be repeated cover. Now some of the lower ground floor of the house to do a half basement treatment, can also play a better role in moisture

- Q: Plastic foam on the floor there is no effect of moisture

- In addition to pad plastic film surface is generally relatively thick, so it will not easily deteriorate, generally do not have what problem, whether it is solid wood or composite floor now installed under the floor are used in this material. Mat close to laying on the ground, a waterproof, moisture-proof, protect the floor, increase the elasticity of the film, the ideal thickness is more than 0.22mm, and has the properties of alkali resistant, acid resistant.

- Q: Home decoration with plastic floor, please? What are its strengths and weaknesses?

- To prevent accidental injury; skid resistant, not affected by temperature, wet deformation, reducing the noise comfortable and 5 color pattern is rich, personalized to meet the actual demand of fire; 6

- Q: How much is a normal plastic floor

- There are many kinds of plastic floor, generally can be divided into suspended plastic floor and PVC plastic floor

- Q: What is the role of badminton PVC plastic floor

- The role of badminton PVC plastic floor is as follows:1, is composed of PVC wear-resistant layer, glass fiber reinforced layer and PVC foam buffer layer composition.2, anti aging and fastening technology, wear resistance, the service life of up to 15 years.

- Q: Plastic floor, is expected to invest much capital investment

- The upstream industries of the new building materials industry include all kinds of raw materials and energy supply enterprises, and the downstream industries include real estate, national defense industry and so on. Through this industry chain, we can see that the new building materials industry's dependence on energy resources is very strong, so the trend of the development of new building materials industry and the introduction of national policies on the use of energy resources are closely related.

- Q: Such as the title, do not know what is the real wood floor shop? The following is the keel I am looking for the materials and the advantages and disadvantages, we have what opinions and suggestions might as well talk about... 4, keel laid the keel: many materials, the most traditional is also plastic, wood keel, wooden keel and so on Aluminum Alloy 1): on the ground drill, fixed wooden keel, wooden keel on surface leveling the floor with a nail, will start...Home renovation renovation of the old house, the living room plus two bedroom only 41 square meters, which is more suitable for...In addition, the room is small, the shop is too thin and good-looking and consumption of materials, want to shop 455*90*1.8 or 455*120*1.8

- Each keel has its advantages, the key is to look at your own budget, and of course, a good money.

1. Manufacturer Overview

| Location | Zhangjiagang, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | Europe; North America; South Amercia; |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Zhangjiagang;Shanghai |

| Export Percentage | 80% - 90% |

| No.of Employees in Trade Department | 150 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | Above 2 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Vinyl (PVC) Flooring - Wood Plank

- Loading Port:

- China Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 X 20'GP m²

- Supply Capability:

- 50 X 20'GP Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords