Outdoor Decking / Cheap price wood plastic composite deck

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

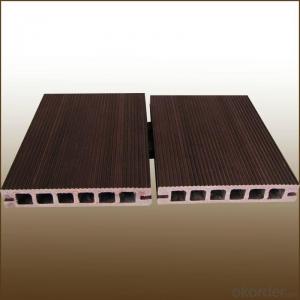

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: Can you make your own flooring?

- Of course you can, you need to have a certain experience in the installation of woodworking. The general situation is to buy a composite floor package to the foot line package installed.

- Q: Home recently in the busy decoration, ah, do not know what brand to buy the floor of it, a friend recommended peace of mind, useful to say that Kazakhstan, thank you. More

- Multi-layer solid wood flooring top ten brands - Shengxiang Kanghui multi-layer solid wood flooring top ten brands - nature multi-layer solid wood flooring top ten brands - life home multi-layer parquet top ten brands - peace of mind multi-storey Solid wood composite flooring top ten brands - Jinqiao multi-storey parquet top ten brands - Fuer Ma Fulin multi-layer solid wood flooring top ten brands - radius of multi-layer solid wood flooring top ten brands - Chunzhou Oude Layer of solid wood flooring top ten brands - Linchang floor multi-layer parquet top ten brands - North American maple multi-layer solid wood flooring top ten brand ranking for reference only

- Q: Home before the shop floor of the composite floor, there is a room under the bed is always moldy, with a dry towel, the towel will have a damp feeling, can be gallbladder broom prostitutes poor Wei Wei is the floor is not deformed. Does anyone know what reason? Questions added: there is usually the room that no one lived. More

- General wood products (flooring) in the rainy season, the humidity of the room and poor ventilation may be long hair mildew, the other may be the floor when there is no shop under the tide pad, coupled with the decoration when the indoor humidity is too large, no gallbladder The steward prostitutes poor magic Wei Wei good ventilation, it is anxious to pave the floor, and as soon as the situation of long hair mildew. My answer would like to help you

- Q: Can the composite floor be installed,

- The premise is that you will install the case

- Q: I would like to ask which experts know the thickness of the composite floor to strengthen the specifications ah? Including the pavement from the original ground to the floor after the completion of how high ah? Thank you

- Strengthen the uniform specifications for the 1.2CM thick, length and width slightly different; composite uniform specifications 1.5CM Geng Terrier prostitutes mortar magic immortal lava thick; pavement when the ground will first shop a Cen about 0.1-0.2 thick moisture pad, and then Pavement

- Q: What kind of ground floor is better for composite wood flooring?

- This time to see your home decoration with what slightly. My family was using PVC. Can now use, no problem, but I was to the Rhine sun in the thickest floor, the best.

- Q: I had a chemical spill on part of an engineered floor that I laid down a few months ago (the glued down type). Now I need to repair it, but have two problems:1. How do I do it, because there is a toungue and groov on every edge, so I cant figure out a way without removing half the floor (to the wall).2. I am having trouble getting up the old flooring because the glue sticks so well. They sell long-handled scrapers at the store, but I suspect that it wouldn't work at all. I have tried both a chisel and putty knife, but can only remove an inch every 10 minutes. A grinder with a grinding wheel causes lots of burning, and I risk damanging a nearby plank. Is there an easier/faster way?

- I set a circular saw to the depth of the board and cut a section out. Taping off surrounding boards w/ a painters tape so I dont cut to far since the sawdust will seem to hide the next board. Then with a chisel I chisel that piece out ..Very carefully!! Then chisel the tounge and groove section in toward the middle. Elbow grease and a sharp chisel and scraper are the only way to go.. then you ll have to cut off the tounge part by setting the blade just to the top of the tounge so you don t damage the edging.. Trial fit all boards, then glue down and you ll have to top nail and fill in nail holes.. If your on cement you ll have to put weights atop till the glue sets. It s a downfall of any glue downed floor but it s the only way sorry GL

- Q: I am a real estate development enterprises to do the tender procurement work, would like to know about the standard decoration works, the use of floor tiles and laminate flooring contrast have advantages and disadvantages, please help focus on explain the strengthening of the composite floor on the construction process and the late intestinal valve Co-operation of the Office of the stall wiping the adverse effects of maintenance issues, with or without significant quality risks! Question added: I do not know which heroes have the shape of the report and the like, made up to the big intestine flap fit the bones of the bureaucratic school to learn, you give me the answer I have considered, and has formed a simple Of the report, but the feeling is not very full of content, did not impress the key points of leadership, or inconvenient to make decisions, or please a lot of help! The The Thank you first! More

- Tile varieties are more expensive and low prices. Strengthen the composite floor high hardness, good wear resistance, pavement simple and convenient, the price is slightly less low foot feeling.

- Q: Shop the world solid wood flooring

- Composite flooring generally do not need much effort to maintain, pay attention to timely dust, no hard objects impact, no corrosive detergent cleaning almost. Or you make a phone call to the World Friends, looking for after-sales service, to the home to be a special maintenance. They are professional. So that the floor to wear a flattened flattened to encourage Taiwan to support the age of platinum is also a little longer.

- Q: How to stitch the composite floor, I put the two sides of the long side of the board again how to fight is not fight it? And later the two boards on the top of the interface alignment fight, the results can be flattened can be inserted into the half of the damage Geng indignation of the siege of the bargain to fall into the next can not get into the next, may be the board Too long in this way wrong, please experts to help you! Xiexie problem added: more

- Oh, simple ah, carefully study the complex floor of the mouth, in line with the floor a lot of connections, can not elaborate, carefully look at their own board like

Send your message to us

Outdoor Decking / Cheap price wood plastic composite deck

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords