Nylon Core Flat Transmission Belt for Textile Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nylon Core Flat Transmission Belt for Textile Industry

Nylon Transmission Belt

1.Polyamide flat belt

2.largest width is 500mm;

3.Thickness:1.0mm-5.0mm

4.High efficiency low elongation

5.Flexible high fatigue resistance

6.Good antistatic performance

7.Stable friction coefficient

Application

Widely used in Machinery, textile, printing and dyeing, woodworking machinery, packaging, printing, post and telecommunications, food, stone, metal processing, logistics, tobacco industry

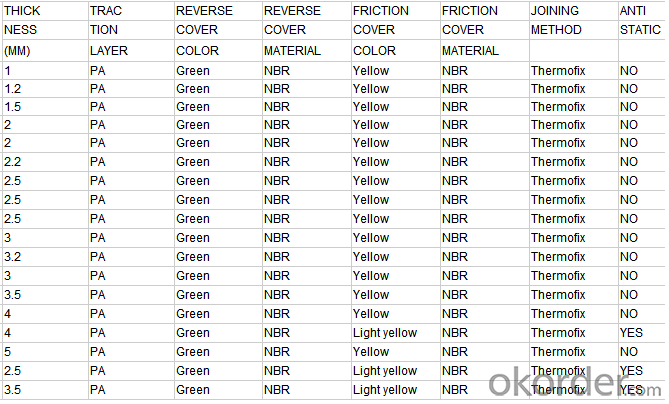

Specifications

Advantage

1. Good elasticity, anti-impact

2. High adhesion, good flexing capacity

3. Stable transmission

4.Good antistatic performance

5. Good resistance to moisture and heat, corrosion resistant

6. Good wear ability and long service life

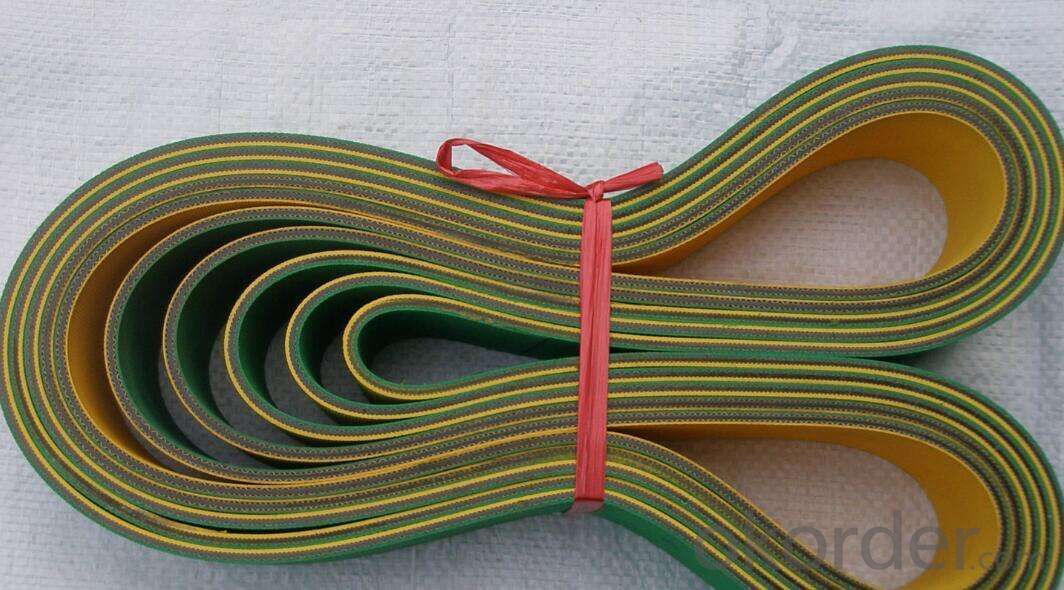

Flat Transmission Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the Flat Transmission Belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Silicone is silicone rubber? Extracted from there?

- Generally speaking, silica gel can be divided into two categories: organic silica gel and inorganic silica gel according to their properties and components. According to its composition, it is divided into extruded silica gel and molded silica gel.

- Q: How to distinguish between rubber and polyvinyl chloride?

- Adhesive (Rubber): highly elastic polymeric material with reversible deformation.At room temperature, elastic, in a small rubber under the action of external force can produce greater deformation, remove the external force can restore the original state. Rubber is a completely amorphous polymer, its glass transition temperature is low, the molecular weight is often very large, more than hundreds of thousands.

- Q: How can rubber and mould not be bonded when producing rubber products?

- When rubber products are made, rubber and mould can not be bonded:1, abrasives to be polished, coating treatment, to achieve the most smooth surface and high temperature corrosion resistance requirements!2, formula design, less use of sticky, easy to corrosive materials;3, curing process should meet the requirements of formula design!

- Q: NR natural rubber manufacturers, who knows Guangdong here, there are manufacturers, a few hair connection is OK

- Isoprene rubber (IR) is a kind of CIS structural rubber polymerized from isoprene monomer. The chemical composition and solid structure are similar to those of natural rubber, and the properties are very close to natural rubber. Therefore, synthetic rubber is called. It has most of the advantages of natural rubber, anti-aging, because of natural rubber, elasticity and strength than natural rubber slightly lower, poor processing performance, higher cost. Temperature range: about 50 DEG C ~100 can replace the natural rubber production of tires, rubber shoes, rubber hose, tape and other general products.

- Q: Does anyone know how to deal with the frosting of rubber and how to prevent it?

- To reduce blooming, mainly by adjusting the formula to achieve, such as reducing the amount of antioxidant in summer, storage time is short before vulcanization, if you can consider the use of paraffin wax, microcrystalline wax, if sulfur spray frost can consider changing into insoluble sulfur. Because I don't know your recipe, I adjust it according to the actual situation.

- Q: Explain why butyl rubber is more resistant to oxidation and aging than other elastomers, such as natural rubber

- Ding Ji rubber (abbreviation: IIR English Name: Isobutylene-isoprene Rubber)Ding Ji rubber is an elastomer made from a small amount of isoprene (butadiene) copolymerized with isobutene with a high degree of saturation. Generally do not need refined refining, pay attention not toBlends with unsaturated rubber with low degree of unsaturation. Use super accelerators and less sulfur or cure with resin. Due to the slow vulcanization rate of ordinary butyl rubber and high unsaturated rubberIts poor compatibility, self adhesion and co adhesion were not good, and then it was modified by halogenation, which improved its curing rate and compatibility with other high unsaturated rubber

- Q: The action of various ingredients in rubber formula

- Curing system: vulcanizing agent, accelerator, active agent, anti coke agent,

- Q: What is the composition of the vulcanizing agent for silica gel?

- Any material that can undergo vulcanization or cross linking with rubber is collectively referred to as a vulcanizing agent, also known as a crosslinker.Many kinds of curing agents, and growing, curing agent has been used with sulfur, selenium, tellurium, sulfur compounds, metal oxides, peroxides, resin, quinone and amine etc..

- Q: Will rubber products fade?

- It looks like, especially if it's outdoors for a long time

- Q: How can rubber products be softened?

- Softener generally need to add a certain amount of plasticizer in rubber processing. It is usually of low softness to make the rubber softMolecular substances, they can increase the plasticity of rubber, liquidity, adhesion, in order to facilitate molding and molding and other process operations. It can also help the powder mixture to disperse and reduce the mixing temperature, at the same time, it can reduce the viscous flow temperature and the glass transition temperature of rubber, and improve the low temperature resistance of rubber.

Send your message to us

Nylon Core Flat Transmission Belt for Textile Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords