Eco-Friendly HPDE Geocells for Nutrition Geotextile in Ecological Prevention and Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

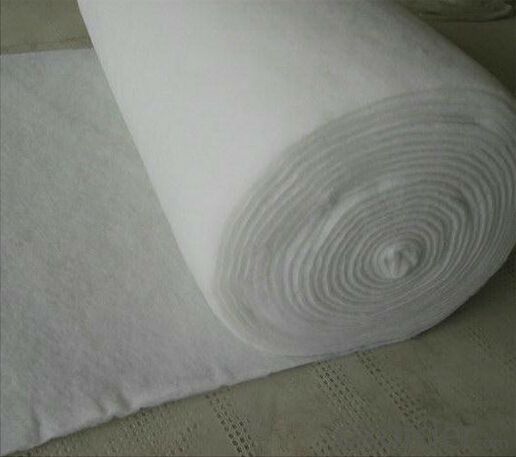

Nutrition geotextile in water environmental engineering .

Specification:

1. 200g/m2-400g/m2

2. One side thermally bonded nonwoven geotextile

3. Both sides thermally bonded nonwoven geotextile

Product Feature:

1. Simple and fast construction

2. Achieve the greening effect quickly after construction

3. Due to the grass and composite fiber fabrics become into one integration, so it has the ability of certain degree of flow resistance for the water rising before the grass survive.

4. Composite fiber fabric is a continuous structure from slope top to slope toe, both ends are fixed, has high water flow resistance.

Technical Specification

5.0 m length and 1.05 m width. Reverse side all used filter material. Grass seeds: Bermuda grass (warm season grass), Bahia grass (warm season grass), Kentucky bluegrass (cold season grass), Tall fescue grass (cold season grass), Red fescue grass (cold season grass). Plant height: 0.1 ~ 0.5 m.

| NO. | Items | Specification | Notes | |||

| 1 | Total unit area weight g/sq.m | ≥380 | ||||

| 2 | dimension | width m | 1.0~2.0 | |||

| length m | as per user’s request | |||||

| 3 | Composite fiber fabrics | Material | Polyester Fiber | High strength PET | ||

| Unit area weight g/sq.m | ≥160 | |||||

| Mesh dimension mm | 8×8 | |||||

| Extension strengh kn/m | ≥11 | MD & CD | ||||

| 4 | Filtra layer | Material | Polyester non woven geotextile | |||

| Unit area weight g/sq.m | ≥40 | |||||

| 5 | Grass seeds, Fertilizer | Type | According to actual situation choose 3~5 grass seeds | |||

| Plant height m | 0.1~0.3 | |||||

| 6 | Fiber layer | Material | wood pulp cellulose | |||

| Unit areaweight g/sq.m | ≥15 | |||||

| 7 | flow resistance | ≥4 | not allow appear scour, suction and blanket turn-over etc. damage phenomenon | |||

| M/s | ||||||

| 8 | Anti-UV strengh conservation rate % | 65~80 | 3000hrs Continuously exposure 3000hrs | |||

| 9 | Supporting spare parts | ABS fastening nail | Material | ABS Resin | Fixed between two blankets by length direction | |

| Fiber diameter mm | 35 | |||||

| Nail length mm | 325 | |||||

| Lnail | Material | Steel wire (content 10% zinc-aluminium alloy) | Used to fix single blanket | |||

| Fiber diameter mm | 4 | |||||

| Nail length mm | 200 | |||||

| ABS connecting nail | Material | ABS Resin | Used in the slope between the two blankets ( width direction) | |||

| Nail length mm | 38 | |||||

| Connecting fiber | Material | High strength Polypropylene | Used in the slope between the two blankets ( width direction) | |||

| Length mm | Cut as per request | |||||

APPLICATION:

Generally laid on the river channel, slope protection etc. slope revetment projects, to control the water erosion, soil loss, meantime can reach the effect of slope ecological restoration and landscape greening, making river back to natural.

- Q: Can geogrids be used in mining tailings containment?

- Yes, geogrids can be used in mining tailings containment. Geogrids are commonly used in mining operations to reinforce and stabilize various types of soil and rock structures, including tailings containment facilities. By providing tensile strength and stability, geogrids can enhance the overall integrity and performance of tailings containment systems, helping to prevent erosion, slope failure, and environmental contamination.

- Q: How are geogrids connected to the surrounding soil?

- Geogrids are connected to the surrounding soil through a process called interlocking. The geogrids have open spaces or apertures that allow soil particles to fill in, creating a bond between the geogrid and the soil. This connection helps improve the stability and load-bearing capacity of the soil, making it more resistant to erosion and preventing the geogrid from slipping or moving out of position.

- Q: What is the cost of geogrid installation?

- The cost of geogrid installation can vary depending on various factors such as the size of the area, the type of geogrid being used, the complexity of the installation process, and the labor costs in a particular location. It is best to consult with a geogrid installation specialist or contractor to get an accurate estimate for your specific project.

- Q: How to connect the geogrid with the panel in the reinforced earth retaining wall?

- When the geogrid is laid in the curve and the corner, the adjacent earthwork grid is currently used in the reinforced earth retaining wall of the assembled panel, and the common wall of the assembled panel module will have gaps or overlaps (see Figure 1). For the outward bending of the geogrid, there are different forms such as rectangle, hexagon, shape, L shape and groove shape. Panel module will appear at the corner of the gap,In order to ensure the continuity of the reinforced soil, laying in the void design based on the engineering environment need to be flexible, prefabricated into various shapes, can provide the same type of geogrid small pieces of good, and cover all the reinforced area; for bend shop visual effect; can also use color cement, add art wall. No panel reinforcement design of geogrid, in the corner there will be some overlap in geogrid, geogrid reinforced earth retaining wall is also called anti package type or wrap-reinforcedearth retaining wall, the wall is made of mesh bags to fill the overlap coefficient of friction will be reduced, must be laying a layer of 10mm ~ 20mm thick the soil geogrid anti package into each layer of geogrid is a special connecting rod is connected with the shape of the coarse sand layer, separate the two layer of Geogrid to ensure friction resistance. As a whole, the mesh bag filling has been mixed for local growth of grass and shrub seeds, seeds, after months of growth after the formation of green ecological wall. The utility model not only protects the safety of the geogrid, but also beautifies the environment of the retaining wall project.

- Q: The effect of steel and plastic grille in steel and plastic grille

- 1 plastic steel plastic grille used to increase the bearing capacity of the road (ground), Yan Changlu (ground) based service life.2 plastic steel plastic grille used to prevent road (ground) surface collapse or crack, keep the ground beautiful and tidy.

- Q: Introduction of steel plastic grille

- Construction technology of steel plastic grille

- Q: How do geogrids help in reducing the use of natural resources?

- Geogrids help in reducing the use of natural resources by providing reinforcement and stabilization to soil structures. They allow for the use of less soil and aggregate materials in construction projects, reducing the need for excavation and mining of natural resources. Additionally, geogrids improve the durability and longevity of structures, reducing the need for frequent repairs or replacements, further conserving natural resources.

- Q: Can geogrids be used in reinforcement of soft soils?

- Yes, geogrids can be used in the reinforcement of soft soils. Geogrids are commonly used in civil engineering applications to stabilize and reinforce weak soils. They provide tensile strength and distribute loads, improving the overall stability and load-bearing capacity of the soil.

- Q: Are geogrids effective in reducing soil settlement?

- Yes, geogrids are effective in reducing soil settlement. Geogrids provide reinforcement and stabilization to the soil, distributing the load more evenly and reducing the potential for settlement. They help to increase the overall strength and stability of the soil, preventing excessive settling and maintaining the integrity of the structure.

- Q: Panzhihua steel plastic composite geogrid manufacturers, how much money, where to sell

- At the same time, the high molecular weight of polyethylene is also sufficient to resist ultraviolet radiation caused by aging. The grille stress aspect rib synergistic effect, can not generate node crack or damage

Send your message to us

Eco-Friendly HPDE Geocells for Nutrition Geotextile in Ecological Prevention and Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords