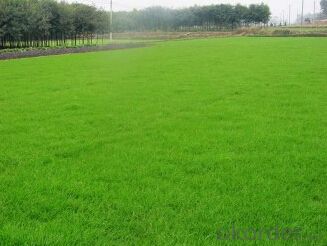

Geogrids and Geomembranes Nutrition Geotextile for Planting Grass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Features:

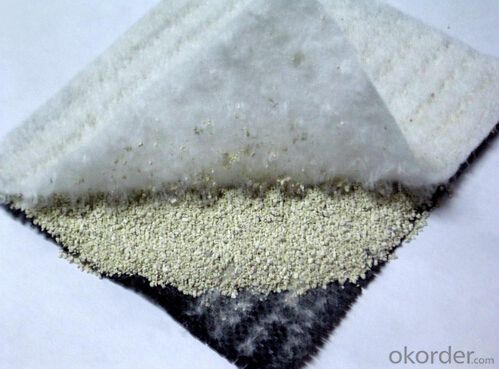

Polyester filament geotextile is made by polyester textile needle consolidation , product specifications from 80-800g/m2 , it is geosynthetic application in geotechnical and civil engineering , they are arranged in three-dimensional structure of the fiber . In addition to having good mechanical properties, but also has a good aspect to the drainage performance and good elongation properties and high resistance to biological , acid , anti-aging chemical stability . Meanwhile , it also has a wide range of pore size , pore distribution tortuous , excellent permeability and filtration performance .

2. Action:

1, Water conservancy project dams and slope of filtration , channel isolation, impervious ;

2, Highways , railways, airport runways based isolation, filtration , drainage, slopes, retaining walls and pavement reinforcement, drainage ;

3, Port engineering soft ground , beach causeway , harbor piers and breakwaters reinforcement, drainage ;

4, Polyester filament geotextile has been widely used in the field of infrastructure construction , and gradually be applied to a wider range of fields.

3. Technical data:

Index | Remark | |||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | ||

Deviation of mass per unit area % | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -5 | -4 | -4 | -4 | |

Thickness mm ≥ | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.2 | 5.5 | |

Width deviation % | -0.5 | |||||||||||

Break strength kN/m | 4.5 | 7.5 | 10.5 | 12.5 | 15 | 17.5 | 20.5 | 22.5 | 25 | 30 | 40 | Vertical and horizontal |

Break elongation % | 40~80 | |||||||||||

CBR bursting strength kN ≥ | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 5.5 | 7.0 | |

Equivalent aperture mm | 0.07~0.2 | |||||||||||

Vertical permeability cm/s | K*(10-4~10-3) | K=1.0~9.9 | ||||||||||

Tear strength kN≥ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.70 | 0.82 | 1.10 | Vertical and horizontal |

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does we support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. How to deal with the sample charge?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information.

At the same time, please rest assured that your information is also safe here.

- Q: How do geogrids enhance the stability of railway track cuttings?

- Geogrids enhance the stability of railway track cuttings by providing reinforcement to the soil. They are placed within the soil layers of the cutting and act as a strong and flexible support system. Geogrids distribute the load more evenly, reducing the stress on the soil and preventing its movement. This helps to prevent slope failures, soil erosion, and overall instability, ensuring the long-term stability and safety of the railway track cuttings.

- Q: Urgent need!!

- Geotextiles are used for road, railway, tunnel, dam, tailings treatment, isolation, filtration, drainage, reinforcement, protection and enhancement...Analysis of the causes of cracks in the asphalt overlay, the formation of a new type of excellent geotechnical substrates by special coating process.Asphalt overlay on old cement concrete pavement is a kind of special pavement structure, and its stress and strain characteristics are quite different from those of general elastic layered system.

- Q: Can geogrids be used in retaining walls for waterfront applications?

- Yes, geogrids can be used in retaining walls for waterfront applications. Geogrids are commonly used in such applications to reinforce and stabilize the soil behind the retaining wall, providing additional strength and preventing potential erosion or failure.

- Q: What are the testing methods for geogrids?

- Some commonly used testing methods for geogrids include tensile strength testing, creep testing, puncture resistance testing, and pullout testing.

- Q: Are geogrids suitable for use in steep slopes?

- Yes, geogrids are suitable for use in steep slopes. Geogrids provide reinforcement and stability to soil, helping to prevent erosion and slope failure. They are designed to withstand high tensile forces and can effectively reinforce steep slopes, making them a suitable solution for such applications.

- Q: How do geogrids enhance the performance of geotextiles?

- Geogrids enhance the performance of geotextiles by providing additional reinforcement and stability to the soil. They work by interlocking with the soil particles and distributing the applied loads more evenly, which helps to prevent soil erosion, improve load-bearing capacity, and increase the overall strength and durability of the geotextile system.

- Q: Do geogrids provide reinforcement to geosynthetic liners?

- No, geogrids do not provide reinforcement to geosynthetic liners. Geogrids are typically used for soil reinforcement applications, such as stabilizing slopes or retaining walls, while geosynthetic liners are used for containment purposes, such as lining landfills or ponds.

- Q: What is the difference between uniaxial and biaxial geogrids?

- Uniaxial geogrids have strength and stiffness in one direction, making them suitable for applications requiring reinforcement in a single direction. Biaxial geogrids, on the other hand, have strength and stiffness in two perpendicular directions, allowing for reinforcement in multiple directions. This makes biaxial geogrids more versatile and applicable to a wider range of projects.

- Q: The difference between the overlap length and the overlapping width of the geotextile in reinforced embankment

- The installation of geotextiles is usually done by means of overlapping, stitching and welding. The width of the stitching and welding is generally 0.1M or more, and the overlap width is generally more than 0.2M.

- Q: What is the market price of the geotechnical grid in 2017?

- (4) the first layer of geogrid paved, began to fill with second layers of 0.2m in thick sand (coarse), the method of sand transport to the site: car unloading to the subgrade side, then put forward to push the bulldozer, within 2 meters on both sides of the subgrade filling after 0.1M, the first layer of geogrid fold up and then fill in 0.1 meters in the sand (coarse), from both sides to the middle filling and advance, prohibit all machinery without filling (coarse sand) of Geogrid on traffic operation, it can guarantee the geogrid is smooth, does not play drums, do not wrinkle, stay in the second layer (coarse) after the formation of sand, the level of measurement, to prevent uneven filling thickness, leveling and correct use of vibratory roller 25T static pressure two times.

Send your message to us

Geogrids and Geomembranes Nutrition Geotextile for Planting Grass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords