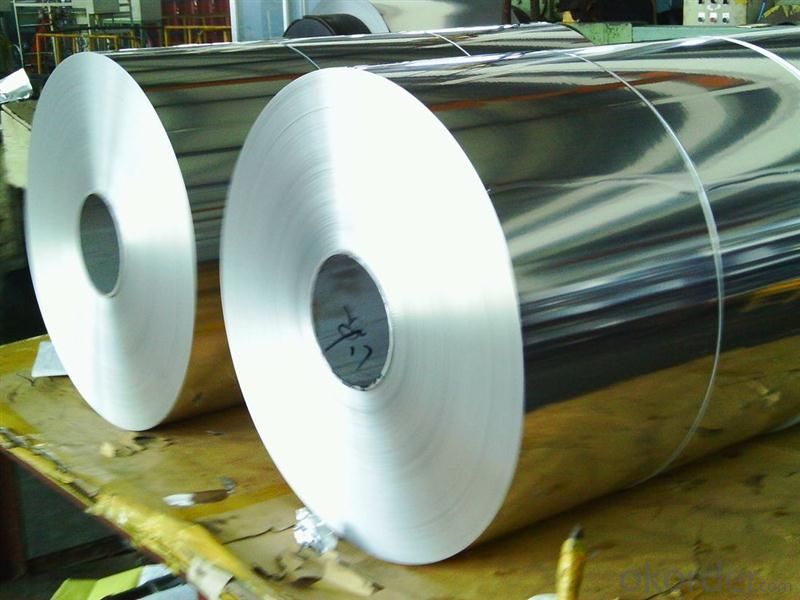

Novelis Aluminum Coil 1060 Temper H18 0.5mm 0.6mm 0.7mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1060 Temper H18 0.5mm 0.6mm 0.7mm Thick Aluminum Coil

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: Are aluminum coils affected by magnetic fields?

- No, aluminum coils are not affected by magnetic fields as aluminum is not a magnetic material.

- Q: I recently had to have a course of B-12 injections (my digestive system was not properly absorbing other forms). While I felt a significant improvement in mood, energy and memory, I was very concerned to discover that the B-12 shot came with a little something extra: aluminum! I'm wondering if the benefits outweigh the potential risks - why is aluminum placed in the injection? (Are there metal free versions out there?)

- Aluminum salts have been used in vaccines for over 80 years now. They are thought to increase the body's immune response to the vaccines although it is not clear to researchers how this works. However, there is no evidence that it is harmful and the only side effect seems to be increased reddness. The odd thing is that there is usually some sort of metal in any vaccine/shot. If not aluminum salts, there's thimerosal (a mercury-based preservative). The CDC says, btw, that there is no proof that thimerosal causes any harm. However, some studies show a link between thimerosal, aluminum, and a host of other preservatives added to vaccines to autism in children. No news on how it affects adults, but research is being done with respect to Alzheimer's disease. Speak to your doctor to find out he/she has 'metal free' versions of vaccines and about your concerns. Such vaccines are available but are usually very costly to obtain manufacture so doctors usually don't order them as a result.

- Q: Describe the various types of coatings applied to steel coils and their applications.

- <p>Steel coils can be coated with several different types of materials to enhance their properties for various applications. Common coatings include: 1) Galvanized coating, which provides corrosion resistance and is used in construction and automotive industries. 2) Pre-painted or color-coated steel, which is coated with organic paint and used for aesthetic purposes in buildings and appliances. 3) Aluminized coating, offering high-temperature resistance and used in heat-treating processes. 4) Zinc-iron alloy coating, which combines the benefits of zinc and iron for enhanced corrosion protection. 5) Organic coatings such as epoxy or polyurethane, used for specific chemical resistance or additional protection in harsh environments. Each type of coating is chosen based on the specific requirements of the end product and the environmental conditions it will face.</p>

- Q: my text says aluminium does not corrode much as a passive aluminium oxide layer is formed on it.Well other metals such as sodium adn potassium also form oxides. Why dont their oxides prevent further oxidation ?

- Not sure. Maybe because Na K are more active than Aluminum.

- Q: Is it possible to utilize steel wires in the creation of jewelry or decorative items?

- <p>Yes, you can use steel wires for making jewelry or decorations. Steel wires are durable and can be shaped into various forms, making them suitable for a range of designs. They are often used in wire wrapping techniques and can be combined with beads or other materials. However, it's important to consider the type of steel used; stainless steel is more resistant to rust and is commonly preferred for jewelry making. Additionally, steel wires may require special tools for cutting and bending, and proper safety measures should be taken during the crafting process.</p>

- Q: What is the maximum width-to-thickness ratio for aluminum coils?

- The maximum width-to-thickness ratio for aluminum coils depends on various factors, including the specific alloy, temper, and intended application. Aluminum coils are commonly used in industries such as construction, automotive, and packaging, where different width-to-thickness ratios may be required. In general, the width-to-thickness ratio for aluminum coils typically ranges between 100:1 to 200:1. However, it is important to note that this range can vary based on the specific alloy and temper. Thicker coils may have a lower width-to-thickness ratio, while thinner coils can have a higher ratio. High-strength alloys, such as those used in aerospace applications, may have lower width-to-thickness ratios due to their increased strength requirements. Conversely, coils used in less demanding applications may have higher width-to-thickness ratios. It is crucial to consult the relevant industry standards, specifications, or manufacturer guidelines to determine the appropriate width-to-thickness ratio for a specific aluminum coil. These guidelines consider the intended use, mechanical properties, and performance requirements, ensuring that the coil is suitable for its intended application while maintaining structural integrity and functionality.

- Q: What is the price range of aluminum coils?

- The price range of aluminum coils can vary depending on various factors such as the thickness, width, alloy type, and market conditions. Generally, the price range for aluminum coils can start from as low as $1 per pound for thinner gauge coils, and can go up to $3 per pound or higher for thicker gauge coils or specialized alloys. It's important to note that these prices are approximate and can fluctuate based on market demand, availability, and other economic factors. It is recommended to contact suppliers or consult market research reports for accurate and up-to-date pricing information.

- Q: Are there any limitations on the bending or shaping of aluminum coils?

- Aluminum coils do have limitations when it comes to bending or shaping. Despite being a soft and malleable metal, there are factors that can affect its bendability. The thickness of the aluminum coil plays a role in its bendability. Thicker coils are generally more difficult to bend compared to thinner ones because they have increased resistance to deformation. The temper or hardness of the aluminum coil also affects its bendability. Different tempers, such as soft, half-hard, or hard, have varying degrees of malleability. Soft tempers are easier to bend, while harder ones require more force and may be prone to cracking or breaking during bending. The desired bend or shape's design and complexity can impose limitations as well. Sharp bends or intricate shapes may cause the aluminum coil to crack or deform, especially if it lacks proper support or if the bending radius is too small. Impurities, defects, or alloying elements present in the aluminum coil can also impact its bendability. These factors can lead to inconsistencies in the material's mechanical properties, making it more susceptible to cracking or breaking during bending or shaping. Therefore, it is crucial to consider the thickness, temper, design, and quality of the aluminum coil to ensure successful and safe bending and shaping.

- Q: This question asks about the common applications of aluminum coil in everyday life.

- <p>Aluminum coil is widely used in daily life due to its lightweight, corrosion resistance, and thermal conductivity. It's commonly used in construction for roofing and siding, in the automotive industry for car parts, and in the packaging industry for food and beverage cans. It's also used in electrical applications like transformers and wiring due to its good conductivity. In the kitchen, aluminum foil is used for cooking and food storage, and in the HVAC industry for heat exchangers and ductwork. Its versatility makes aluminum coil an essential material in many industries and everyday applications.</p>

- Q: i have some questions about aluminum can recycling??:how much can you get from doing that??where can i take them in indianapolis, in???and what else could i recycle??its good for the earth and i need some money!! :) :D thanks!!! :)

- They are worth about $0.01 per can. You can take them to any scrap metal yard.

Send your message to us

Novelis Aluminum Coil 1060 Temper H18 0.5mm 0.6mm 0.7mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords