1100 Aluminum Coil Price Non-Stick Round Aluminum Circle Disk for Utensils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of Non-Stick Round aluminum Circle Disk for Utensils

Alloy: 1050, 1070, 1100, 3003, etc

Thickness: 0.5mm~4mm

Temper: O, H14

Diagonal: 100mm - 1200mm

2. Application of Non-Stick Round aluminum Circle Disk for Utensils

Aluminium Circle is widely used for kitchen wares including fried pans, non-sticky pans, cooking pots, hard anodize cook ware, pressure cooker and house hold utensils etc.

3. Feature of Non-Stick Round aluminum Circle Disk for Utensils

Aluminium Circle has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

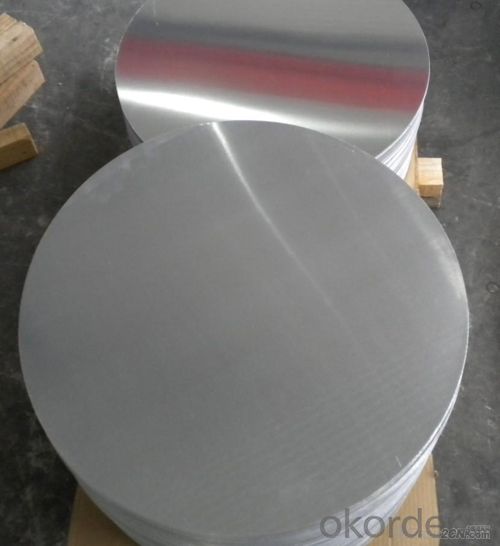

5. Image of Non-Stick Round aluminum Circle Disk for Utensils

6. Package and shipping of Non-Stick Round aluminum Circle Disk for Utensils

eye to sky

eye to wall

with wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the typical hardness of aluminum coils?

- The hardness of aluminum coils can vary depending on different factors, such as the composition of the alloy, the process of tempering, and the intended use. Manufacturers produce aluminum coils with different levels of hardness to meet various needs and requirements. Aluminum coils are available in different tempers, including soft, half-hard, and full-hard. Soft aluminum coils have low hardness and are highly malleable, making them suitable for applications that require easy shaping, such as packaging and wrapping materials. Half-hard aluminum coils are moderately hardened and offer a balance between formability and strength, making them suitable for applications like roofing and siding. Full-hard aluminum coils have the highest hardness and provide excellent strength, making them ideal for applications that require structural integrity, such as automotive parts and construction materials. To determine the specific hardness of aluminum coils, various testing methods can be used, such as Rockwell hardness, Vickers hardness, or Brinell hardness. These tests measure the resistance of the aluminum surface to indentation and provide a numerical value indicating the material's hardness. However, it is important to consult the manufacturer or supplier for the specific hardness values, as they can vary depending on the specific alloy and temper of the aluminum coil.

- Q: What are aluminum coils used for and what are their applications?

- <p>Aluminum coils are versatile metal products that serve various purposes. They are primarily used in construction, manufacturing, and packaging industries. Some common applications include roofing and siding materials, heat exchangers, food and beverage cans, automotive parts, and electrical components. Aluminum coils are valued for their lightweight, corrosion resistance, and high thermal and electrical conductivity, making them ideal for a wide range of applications where durability and efficiency are required.</p>

- Q: What are the rules and regulations regarding the use of aluminum coil in commercial kitchen settings?

- <p>Yes, there are regulations on the use of aluminum coil in commercial kitchens. These regulations often relate to food safety, hygiene, and the material's suitability for contact with food. Aluminum is generally safe for food contact, but it must meet specific standards to ensure it does not leach harmful substances into food. Regulations may vary by country or region, with some areas having strict guidelines on the types of aluminum alloys allowed and their intended use. Compliance with these regulations is crucial to avoid health risks and legal penalties. It's important for commercial kitchens to use food-grade aluminum and to follow local health department guidelines.</p>

- Q: Can aluminum coils be used in aerospace heat exchangers?

- Aerospace heat exchangers can indeed utilize aluminum coils. In the aerospace industry, aluminum is widely employed due to its lightweight nature and exceptional thermal conductivity. Heat exchangers play a critical role in aerospace systems by transferring heat between different mediums. Aluminum coils effectively conduct heat, making them suitable for aerospace heat exchangers. Moreover, aluminum's resistance to corrosion is essential in the challenging environments encountered in aerospace applications. Additionally, its low density contributes to fuel efficiency by reducing the overall weight of aircraft. Hence, aerospace heat exchangers prefer aluminum coils owing to their outstanding thermal conductivity, lightweight properties, and corrosion resistance.

- Q: What is the reason for the grooves that go around the circumference of a tin/aluminium can? It can't be for grip because they're covered with paper anyway and i don't think it would make much difference.

- To allow for expansion and contraction when temperature varies. (Strength would be from Vertical grooves). (Thanks (Ω)Jack).

- Q: how many chloride ions are present? how many chlorine ions are present? what is the mass in grams of one formula unit of aluminum chloride?

- Aluminum Chloride is simply AlCl3 So In each mole of AlCl3 there are 1 mol of Al 3 mol of Cl We know (from periodic table), 1 mol of Al weighs 26.98 g 1 mol of Cl weighs 35.47g so 1 mol of AlCl3 weighs 26.98g + 3x35.47g = 133.39 g sooo moles of AlCl3 = 37.2 g /133.39 g/mol = 0.279 mol in one mol of anything, there are 6.02 x 10 ^ 23 of that thing... so we have 0.279 mol x 6.02 x 10 ^ 23 molecules /mole = 1.68 x 10 ^ 23 And, we know one molecule of AlCl3 dissociates into one Al ion and 3 Cl ions sooo 1.68 x 10 ^ 23 AlCl3 ions dissociate into 1.68 x 10 ^ 23 Al ions so answer is 1.68 x 10 ^ 23 Al ions

- Q: If you were to make something from each of these.which is more expensive? aluminum or carbon fiber ?which is stronger?What would the advantages or disadvantages of each be?

- This Site Might Help You. RE: aluminum vs carbon fiber ? If you were to make something from each of these. which is more expensive? aluminum or carbon fiber ? which is stronger? What would the advantages or disadvantages of each be?

- Q: Can aluminum coils be used in the production of railway tracks?

- No, aluminum coils cannot be used in the production of railway tracks. Railway tracks are typically made of steel for several reasons. Steel is a strong and durable material that can withstand the heavy loads and constant wear and tear of train traffic. It also has good heat resistance and can maintain its structural integrity under high temperatures, which is important for tracks that are exposed to friction and heat generated by moving trains. Aluminum, on the other hand, is a lighter metal with lower strength and poorer heat resistance compared to steel. While aluminum may be used in other components of railway infrastructure, such as electrical wires or certain parts of trains, it is not suitable for the production of railway tracks themselves.

- Q: What are the typical lead times for aluminum coil orders?

- Lead times for aluminum coil orders can vary due to several factors. Standard orders typically take anywhere from a few weeks to a few months to fulfill. The size and complexity of the order, availability of raw materials, production capacity of the supplier, and any customization requirements all influence these lead times. Larger or more specialized orders may have longer lead times, especially if they need extra processing or finishing. Transportation and logistics can also affect lead times. To obtain an accurate estimate for a specific aluminum coil order, it is advisable to directly communicate with the supplier.

- Q: What are the different coil winding options available for aluminum coils?

- Some of the different coil winding options available for aluminum coils include: 1. Layer winding: This involves winding the aluminum coil in a single layer, where each turn is adjacent to the previous one. This method ensures uniform distribution of the winding and is commonly used for small to medium-sized coils. 2. Pancake winding: In pancake winding, the aluminum coil is wound in a flat, spiral shape. This method is often used for large coils as it allows for efficient use of space and easy handling during transportation. 3. Concentric winding: Concentric winding involves winding the aluminum coil in multiple layers, with each layer placed concentrically around the previous one. This method is suitable for coils that require higher power and voltage ratings. 4. Random winding: Random winding refers to a method where the aluminum coil is wound in a non-uniform or irregular pattern. This technique is typically used for special applications or when the coil needs to fit into a specific space or shape. Overall, the choice of coil winding option depends on factors such as coil size, power requirements, space limitations, and specific application needs.

Send your message to us

1100 Aluminum Coil Price Non-Stick Round Aluminum Circle Disk for Utensils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords