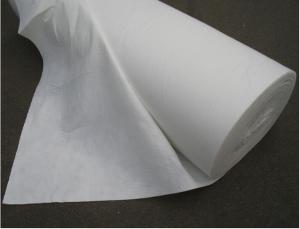

Permeable Needle Punched Short Fiber Nonwoven Polyester Geotextile Membrane 100g for Construction Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

1. Specifications of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

Specifications: 100gsm-800gsm

Width: 1-6m

Length: 50-100m or as request

Property: good flexibility, permeability, filtration, separation and easy for consturction

2. Technicial Data of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

No. | Item | Specification | Note | ||||||||||

Mass per square meter g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | ||

1 | Weight Variation % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

2 | Thickness mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width Variation % | -0.5 | |||||||||||

4 | Breaking Strength KN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD and CD |

5 | Elongation at Break % | 25 ~ 100 | |||||||||||

6 | CBR Mullen Burst Strength KN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

7 | Sieve Size 090 mm | 0.07 ~ 0.2 | |||||||||||

8 | Vertical Permeability Coefficient cm/s | k× (0.1 ~ 0.001) | k=1.0-9.9 | ||||||||||

9 | Tear Strength KN | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | MD and CD |

Needle punched geotextile after treatment method | |||||||||||||

3. Packing of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

4. Application of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

In the area of highway, railway, dam, reclamation for filtration, separation drainage and protection.

- Q: Characteristics of filament geotextile

- It can replace the traditional engineering materials and construction methods, construction safer, and contribute to environmental protection, can be more economical, effective and lasting solution to the basic problems in the construction. Filament geotextile has good mechanical function, good water permeability, and can be anti-corrosion, anti-aging, with isolation, filtration, drainage, protection, stability, reinforcement and other functions, to adapt to uneven grass-roots, Damage, creep small, long-term load can still maintain the original function. Filament geotextile characteristics: strength - the same weight under the specifications, the tensile strength are higher than other acupuncture non-woven fabrics; anti-ultraviolet light - with high UV resistance; high temperature resistance - resistance High temperature up to 230 ℃, high temperature remains structural integrity and the original physical properties; permeability and flat drainage - geotextile thick and is needle-shaped, with good surface drainage and vertical permeability, years later Can maintain this performance; creep resistance - geotextile creep resistance is better than other geotextiles, so long effect is good. It can resist the erosion of common chemical substances in soil and resistance to gasoline, diesel and other corrosion; ductility - geotextile under a certain stress has a good elongation, so that it can adapt to uneven irregular base; Cloth technical features: thick geotextile, geotextile can guarantee the three-dimensional porosity, is conducive to the realization of excellent hydraulic performance. Geotextile break strength has a great advantage, especially for retaining walls and embankment reinforcement. Geotextile indicators are more than the national standard, is an excellent geotextile reinforced materials.

- Q: What are the different functions of geotextiles in geoenvironmental engineering?

- Geotextiles serve various functions in geoenvironmental engineering, including erosion control, soil stabilization, drainage, filtration, and reinforcement. These materials prevent soil erosion by acting as a barrier against water flow and wind forces. They also stabilize soil by improving its mechanical properties, preventing soil movement and settlement. Geotextiles facilitate drainage by allowing water to pass through while retaining soil particles. They serve as a filtration layer, separating different soil layers and preventing the migration of fine particles. Additionally, geotextiles are used for reinforcement purposes, enhancing the strength and load-bearing capacity of soil structures.

- Q: What are the specifications for geotextiles in coastal protection projects?

- The specifications for geotextiles in coastal protection projects typically include factors such as the material type, tensile strength, permeability, and UV resistance. Additionally, the specifications may also outline requirements for installation methods and durability to ensure the geotextiles effectively mitigate erosion and provide long-term stability to coastal areas.

- Q: How do geotextiles affect visual aesthetics?

- Geotextiles, being a synthetic fabric, can often blend seamlessly with the surrounding environment due to their neutral color and texture. This can enhance the visual aesthetics of an area by creating a more cohesive and harmonious appearance. Additionally, geotextiles can be used to stabilize soil and prevent erosion, leading to a more visually pleasing and well-maintained landscape.

- Q: What glue glue is used at the seams of the impervious geotextile

- What glue glue is used at the seams of the impervious geotextile

- Q: Can geotextiles be used in the protection of shoreline structures?

- Yes, geotextiles can be used in the protection of shoreline structures. Geotextiles act as a barrier against erosion by stabilizing the soil and preventing it from being washed away. They can be used in various shoreline applications such as revetments, breakwaters, and coastal dunes to enhance their stability and longevity. Geotextiles also provide filtration and drainage capabilities, allowing water to flow through while preventing soil loss. Overall, geotextiles are an effective solution for protecting shoreline structures from the damaging effects of waves, tides, and currents.

- Q: Geotextile grip test how to do? What is the step?

- Is said to be the strength test or the pull strength test. Can be based on relevant standards. For example: SL / T235-1999 standard, which has the relevant test method.

- Q: Can geotextiles be used in canal lining projects?

- Yes, geotextiles can be used in canal lining projects. Geotextiles are commonly used to provide stability, reinforcement, and filtration in various civil engineering projects, including canal lining. They help to prevent erosion, control water flow, and enhance the overall performance and durability of the canal lining system.

- Q: How do geotextiles contribute to soil compaction control?

- Geotextiles contribute to soil compaction control by acting as a barrier between the soil layers, preventing them from mixing and reducing the risk of compaction. They distribute the load applied on the soil more evenly, reducing the pressure on the soil particles and minimizing compaction.

- Q: What are the advantages of using geotextiles in shoreline stabilization?

- Geotextiles offer several advantages in shoreline stabilization. Firstly, they act as a barrier, preventing erosion caused by waves, tides, and currents. They effectively hold the soil in place, reducing the risk of land loss and maintaining the integrity of the shoreline. Secondly, geotextiles are permeable, allowing water to pass through while retaining the soil particles, which helps in maintaining a stable and balanced ecosystem. Additionally, they are durable and resistant to UV degradation, ensuring a long lifespan and reducing the need for frequent maintenance. Lastly, geotextiles are easy to install and cost-effective compared to traditional methods, making them a practical choice for shoreline stabilization projects. Overall, geotextiles provide a sustainable and efficient solution to protect and enhance coastal areas.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Permeable Needle Punched Short Fiber Nonwoven Polyester Geotextile Membrane 100g for Construction Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords