Geotextile Fabric Under Gravel Needle Punched Polyester/Polypropylene Nonwoven Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Needle Punched Polyester/Polypropylene Manufacturer Nonwoven Fabric Non Woven Geotextile

Desciriptions:

Polyester Nonwoven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications.Made from PP (polypropylene) or PET (polyester) short fiber by nonwoven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance etc. function. It separates, stabilizes, and reinforces soils and allows for filtration Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

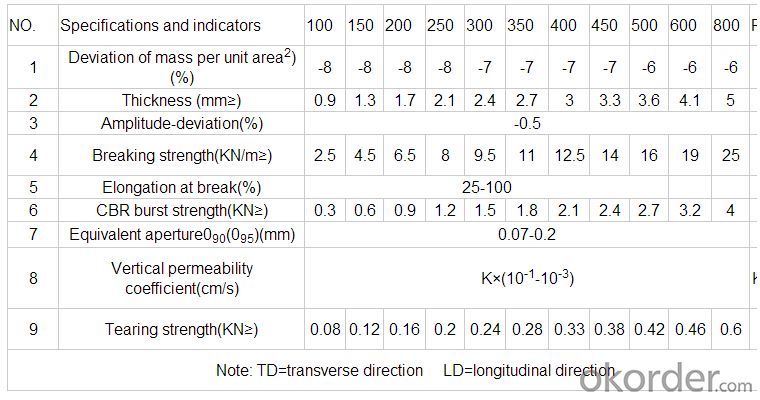

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

1. Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti-oxidation

2. Separation, filtration, drainage, reinforcement, protection, and maintenance function

Details of our products:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles help with subgrade stabilization?

- Geotextiles help with subgrade stabilization by providing a strong, flexible, and permeable layer that separates the subgrade soil from the overlying layers. This prevents the mixing of different soil layers, increases the load-bearing capacity of the subgrade, reduces settlement and deformation, and improves overall stability and performance of the pavement or structure.

- Q: Are geotextiles suitable for use in rain garden systems?

- Yes, geotextiles are suitable for use in rain garden systems. Geotextiles help to retain and filter water, prevent soil erosion, and provide stability to the rain garden system. They also allow water to infiltrate slowly, reducing runoff and promoting better water management in rain gardens.

- Q: How do geotextiles help with reinforcement of geotextile tubes?

- Geotextiles help with the reinforcement of geotextile tubes by providing additional strength and stability. They act as a barrier between the soil and the tube, preventing soil erosion and maintaining the integrity of the structure. The geotextiles distribute the load evenly and reduce the risk of punctures or tears in the tube, thereby enhancing its overall performance and longevity.

- Q: What are the maintenance requirements for geotextile-reinforced slopes?

- The maintenance requirements for geotextile-reinforced slopes typically involve regular inspections, monitoring for signs of erosion or instability, and addressing any identified issues promptly. This may include repairing or replacing damaged geotextiles, reinforcing the slope with additional materials if necessary, and implementing erosion control measures such as vegetation or drainage systems. Regular maintenance and timely interventions are essential to ensure the long-term stability and effectiveness of geotextile-reinforced slopes.

- Q: What are the different geotextile erosion control products available in the market?

- There are several geotextile erosion control products available in the market, including geotextile mats, geotextile tubes, geotextile blankets, and geotextile grids. These products are designed to prevent soil erosion by providing stability, filtration, and reinforcement to the soil. Geotextile mats are typically used for slope stabilization, while geotextile tubes are commonly used for shoreline protection and dewatering applications. Geotextile blankets are used for erosion control on steep slopes and channels, and geotextile grids are often used for soil stabilization in areas with heavy traffic or high loads.

- Q: What are the advantages of using geotextiles in hydraulic applications?

- Geotextiles offer several advantages in hydraulic applications. Firstly, they provide excellent filtration properties, allowing water to pass through while retaining soil particles. This helps in preventing soil erosion and maintaining the stability of hydraulic structures. Secondly, geotextiles act as a barrier against soil migration, reducing the likelihood of clogging or blockage in drainage systems. Additionally, they enhance the overall durability and longevity of hydraulic structures by distributing loads and reducing stress on underlying soils. Lastly, geotextiles are lightweight and easy to install, making them a cost-effective solution for various hydraulic projects.

- Q: Are geotextiles suitable for use in geocells?

- Yes, geotextiles are suitable for use in geocells. Geotextiles provide reinforcement, filtration, and erosion control within geocell systems, enhancing their overall performance. The geotextiles used in geocells help distribute loads, prevent soil erosion, and promote proper drainage, making them a valuable component in geocell applications.

- Q: Why the durability of filament geotextile is relatively strong

- The reason for raw materials

- Q: Do geotextiles have any environmental benefits?

- Yes, geotextiles have several environmental benefits. They help in erosion control by stabilizing soil and preventing sediment runoff into water bodies. They also aid in vegetation growth by retaining moisture and promoting root development. Geotextiles can reduce the need for chemical herbicides and fertilizers by acting as a physical barrier against weed growth. Additionally, they can enhance the efficiency of drainage systems, reducing the risk of waterlogging and promoting groundwater recharge. Overall, geotextiles contribute to sustainable land management practices and help protect the environment.

- Q: What are the factors to consider when designing geotextile-reinforced slopes?

- When designing geotextile-reinforced slopes, several factors need to be considered. These factors include the type and strength of the soil, the slope angle, the water conditions, the expected load and stress on the slope, the desired vegetation cover, and the available space for construction. Additionally, the design should account for the potential for erosion and the need for drainage to prevent water buildup. The selection of appropriate geotextile materials and installation techniques is also crucial for ensuring long-term stability and effectiveness of the reinforced slope.

Send your message to us

Geotextile Fabric Under Gravel Needle Punched Polyester/Polypropylene Nonwoven Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords