Needle Punched Nonwoven Geotextile Polyester and Polypropylene

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of our Geotextile:

- High Strength

- Anti-aging

- Anti-acid and alkali

- Abrasion resistng

- Flexibility

- Easy for construction

- Exprot Europe, Africa for years

- PP Nonwoven geotextile fabric

2. Gextextile Product Description:

--Our geotextile can be made of polypropylene (PP) or polyester (PET) .

-- The weight is available from 100g/m2 to 1500g/m2 and the width from 1m to 8m,

-- Two kinds of processing technical to select: needle punched and thermally bonded, long fiber or short fiber.

-- It is widely known as earthwork material and industry fabric, used in the areas of railway, highway, water conservancy, dam, tunnel,

subway, environment protection and so on.

-- We can supply different specifications as customers’ request.

3. Geotextile Product Specification / Models:

Material: polypropylene (PP) thermally bounded

Weight: 100g/m2-1200g/m2

Width: 1-8m

Length: As customers’ demand (usually is 100m)

Package: PE film and woven cloth

Delivery time: With in 3weeks after received the advance payment

Payment terms: T/T 30% in advance+T/T 70% against the copies of original documents or L/C

4. Application of Geotextile:

1. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule

from passing, it allows the water and the gas pass through freely.

2. Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill,

different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3. Reinforcement

The highway, railway, soilstone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress,

prevents the side-displacement of the earth body and improves the earth body stability.

Technical specification of short fiber needle punched non-woven geotextiles:

According to GB/T17638-1998 Standard

No. | Item | Specification | Note | ||||||||||

Mass per square meter g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | ||

1 | Weight Variation % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

2 | Thickness mm ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width Variation % | -0.5 | |||||||||||

4 | Breaking Strength KN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD and CD |

5 | Elongation at Break % | 25 ~ 100 | |||||||||||

6 | CBR Mullen Burst Strength KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

7 | Sieve Size 090 mm | 0.07 ~ 0.20 | |||||||||||

8 | Vertical Permeability Coefficient cm/s | k× (10-1 ~ 10-3) | k=1.0-9.9 | ||||||||||

9 | Tear Strength KN ≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD and CD |

Needle punched geotextile after treatment method | |||||||||||||

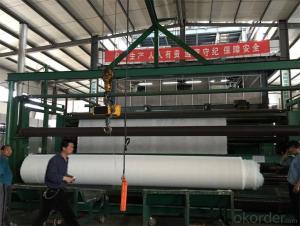

5. Geotextile Products Show:

6. FAQ of our geotextile:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q:What are the popular clothing materials in the market now? How do you distinguish them?

- Twill fabric: warp and weft are woven at least once between two yarns, and the fabric structure is changed by adding warp and weft points, collectively referred to as twill.Fabric features: there are positive and negative points, a complete organization, the cycle of less weaving point, long floating line, soft feel, tissue fabric density is higher, the product is relatively strong, three-dimensional organization strong sense. There are 30 branches, 40 branches and 60 branches.Twill fabric classification: 40 twill fabric, printed fabric (activity of some businesses called flower satin, to illustrate the high-grade fabrics, but in fact he does not belong to the satin fabric), sanding fabric, satin fabric, jacquard fabric, cotton jacquard fabric, satin fabrics etc..

- Q:What fabric is acrylic?

- Acrylic fabric. After treatment, more outdoor products are used. Good color fastness, good ventilation! Haining Yake industry specializing in the production of this kind of cloth!

- Q:What are the advantages and disadvantages of pure cotton fabrics?

- (1) at 110 centigrade below, will only cause the fabric of moisture evaporation, the fiber is not damaged, at room temperature, washing and dyeing had no effect on the fabric, improve the fabric wash wear performance.(2) cotton fiber is naturally resistant to alkali, and fiber should not be destroyed by alkali, which is beneficial to washing clothes. And dyeing, printing and other processes.Environmental protection: cotton fiber is natural fiber. Pure cotton fabric contact with the skin without any stimulation, beneficial to the human body harmless.

- Q:What's the material of velvet?

- The structure of velvet is made up of weft knitted fabric, which is generally divided into ground yarn and Terry yarn. Raw materials are made of cotton, silk, viscose, polyester and nylon. Different materials can be woven according to different uses. Velvet used as clothing, usually cotton yarn as terry yarn, velvet velvet plump, soft feel, comfortable to wear, beautiful and generous.

- Q:What fabric is T/R?

- T/R stands for polyester and viscose blends.These are mainly to express the material composition of fabric, TTerylene (Di Guan) is a synthetic fiber in an important species, is our country's polyester fiber commodity name. R:Rayon (Lei Ying), also made from rayon, is a man-made fiber. Made from natural plant cellulose, so strictly speaking, does not belong to synthetic fibers.

- Q:100% viscose fabric (artificial leather base cloth) is what

- And plain weave cloth (pound cloth), which does not have elasticity. Shoe for more.There are elastic knitted cloth, the cloth ground has a tensile force for car door more leather. The price is relatively high.

- Q:40 cotton and 60 cotton. Which one is good?

- Jacquard fabric: fabric warp and weft of organizational change with the formation of flowers, fine yarn, raw cotton on demanding. And the difference between the monochromatic and polychromatic dyeing technology of jacquard jacquard, jacquard fabric, jacquard monochrome dyeing jacquard fabric woven by good jacquard fabric after dyeing and finishing, the fabric product is solid; color jacquard yarn dyed jacquard fabric, as first yarn dyed after lewd jacquard loom system, finally so the yarn dyed jacquard fabric finishing, there are more than two kinds of colors, fabrics, rich colors, not drab, flower type three-dimensional sense of strong, higher grade. Fabric width of 2 meters 5, pure cotton fabric has shrunk slightly, no pilling, no fading.Satin fabric: warp and weft yarn at least every three interwoven only once, so the satin weave the fabric density is higher, so the fabric more solid. Satin weave higher than similar products of plain, twill products cost. The satin weave fabric called Satin fabric. Satin fabric has the positive and negative points, a complete interleaving point cycle in the least, floating line is the longest, the surface of the fabric almost entirely by warp or weft float lines, satin fabric is soft. The cloth is smooth, delicate and lustrous.

- Q:What's the effect of blending? Why blending? How is blending defined?

- Blended fabric is cotton, chemical fiber and other silk, hemp textile products of natural fiber blended yarn fabric. For example: polyester cotton, polyester wool gabardine etc.. For example, polyester / cotton blended fabric is made of polyester fiber. It is made of 65%-67% polyester and 33%-35% cotton blended yarn. The polyester cotton fabric, commonly called cotton, is really cool. Features: not only highlights the polyester and cotton fabric style strengths in dry and wet conditions and better flexibility and abrasion resistance, dimensional stability, small shrinkage, with tall and straight, not easy to fold, easy to wash, dry, not with high iron and soaked in boiling water.

- Q:What exactly is the fabric count of the bedding? What does the number represent?

- The count is the standard of the yarn's thickness. For example, one or two cotton can be made into 30 1 meters of yarn, that is 30, and one or two cotton can be made 40 long 1 meters of yarn, that is, 40;

- Q:What material is the Gong Duan?

- Twill: the warp and weft are interleaved at least once between the 1 yarns, i.e., 2, 1, or 3. The fabric structure is changed by adding warp and weft points, which is called twill fabric. This kind of cloth is characterized by its relatively thick and strong three-dimensional structure. There are 30 branches, 40 branches and 60 branches.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Needle Punched Nonwoven Geotextile Polyester and Polypropylene

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords