Geotextil Pavco Needle Punched Polyester Nonwoven Geotextile Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Needle Punched Polyester Nonwoven Geotextile Fabric:

We have own lines to produce lower weight to 80gsm by needle punched, the main width is within 240cm or to 800cm:

Main Features of Needle Punched Polyester Nonwoven Geotextile Fabric:

1.100% pet

2.Width:58"

3.Basic weight: 80-500gsm

4.Color various

| material | 100% polyester |

| width | 58", or as customized |

| weight | 80gsm-500gsm |

| color | white color is mainly, other colors can provide accordingly |

| pattern | dyed |

| style | plain |

| nonwoven technics | Needle punched |

| feature | eco-friendly, anti-static, breathable, tear-resistant |

| application | widely used in the reinforcing, lamination material, hometextiel, packing, interlining, construction, filtering, mattress, etc. |

| payment | T/T or L/C |

Specifications of Needle Punched Polyester Nonwoven Geotextile Fabric:

1.woven geotextile(reinforced geotextile)

2.Materials:PP

3.Tensile strength:15~100kn/m

4.Unit weight:100~400g/m2

5.Width:1 ~ 6m

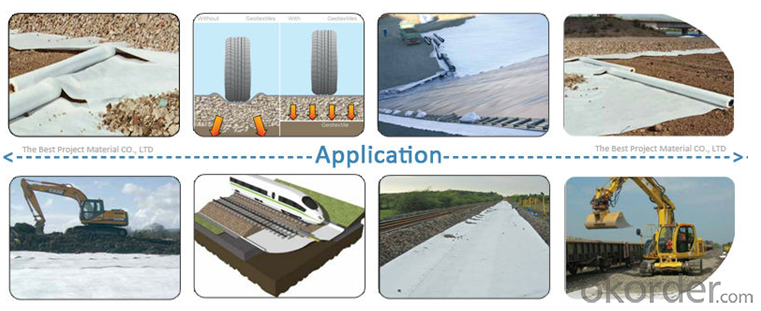

Applications of Needle Punched Polyester Nonwoven Geotextile Fabric:

While the nonwoven fabric can be used in almost any stabilization,separation or cushioning application,they are most commonly used in areas that also require filatration.The non woven design of the material provides a higher rate of flow through,making it easier for water to pass through the material.

Some commen uses of the material includes the following:

1.Road stabilization applications

2.Roofs

3.Civil applications

4.Railway work

5.Landfill lining

6.Trenches

7.Dams

8.Fitration under rip rap and rocks

9.Environmental applications

IMages of Needle Punched Polyester Nonwoven Geotextile Fabric:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Concrete panel shop asphalt do not add geotextiles

- Plus no geotextile cloth according to the design requirements and construction specifications. Generally require high road construction need to lay geotextile. Geotextile manufacturers to answer your questions

- Q: Garden engineering. Do the roof of the hydrophobic board and geotextile roof, would like to know the hydrophobic board and geotextile "sub-project name" and "hidden project"

- Weiyu geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protective effect, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance.

- Q: How do geotextiles help with load distribution in pavement systems?

- Geotextiles help with load distribution in pavement systems by providing a flexible and stable foundation. They act as a reinforcement layer, spreading the load from traffic evenly across the pavement surface. This helps to prevent the formation of stress points and reduces the risk of pavement failure. Geotextiles also help to reduce the amount of rutting and cracking in the pavement, leading to increased durability and longevity of the road.

- Q: How do geotextiles contribute to the stability of railroad ballast?

- Geotextiles contribute to the stability of railroad ballast by providing separation, filtration, and reinforcement functions. They act as a barrier between the ballast and underlying soil, preventing the mixing of materials and maintaining the integrity of the track system. Geotextiles also help to filter out fine particles, preventing clogging and maintaining proper drainage. Additionally, they provide reinforcement, distributing the load more evenly and reducing the potential for settlement and deformation. Overall, geotextiles enhance the stability and longevity of railroad ballast, improving the performance of the track system.

- Q: GB waterproof geotextile what price

- The price of Guobao waterproof geotextile is calculated according to the weight per square meter. For more information, please contact us.

- Q: How do geotextiles help with asphalt pavement reinforcement?

- Geotextiles help with asphalt pavement reinforcement by providing a strong and stable base for the asphalt layer. They prevent the mixing of different soil layers, distribute loads evenly, and increase the tensile strength of the pavement. Additionally, geotextiles help to reduce cracking, rutting, and other forms of pavement distress, resulting in a longer-lasting and more durable road surface.

- Q: Geotextile vertical and horizontal stretching the gap is too much how to adjust

- Geotextile longitudinal and horizontal tensile strength of the gap adjustment, mainly in the carding, laying the net, drawing three links to control, sort out the ratio of Daofu regulation, shop layer, shop curtain speed ratio, Sticks, input and output differences, and so are the cause of a huge gap, the other fiber curl, and so is the key. For the above adjustment, you will find the law. In order to geotextile stretch the vertical and horizontal adjustment equal.

- Q: How do geotextiles help with filtration in drainage systems?

- Geotextiles act as a barrier in drainage systems, allowing water to pass through while preventing the passage of soil particles or other contaminants. By filtering out these particles, geotextiles help maintain the integrity and functionality of the drainage system, ensuring efficient water flow and preventing clogging or blockages.

- Q: Geotextile geomembrane factory need to record, certificate, inspection report?

- Do not need to see if the time is not your company's chapter to know ah

- Q: Where to sell black geotextile prices

- I have 6 meters per square meter to 1 block

Send your message to us

Geotextil Pavco Needle Punched Polyester Nonwoven Geotextile Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords