Multistage Booster Water Pump for Pump Station

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

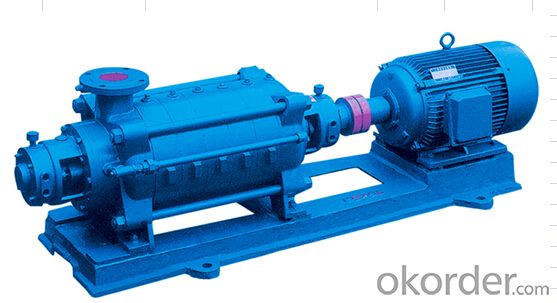

Multistage Booster Water Pump for Pump Station

1.Structure of Multistage Booster Water Pump for Pump Station

The high presuure boiler feed multistage water pump is a horizontal multistage centrifugal pump and suitable for transporting pure water,both ends of it are supported,the casing portion is a senctional form,it is connected and actuated by motor via a resilient clutch.From the driven direction,the pump rotated direction is clockwise.

2.Main Features of Multistage Booster Water Pump for Pump Station

• High Effiency

•Low noise

•Long life, OEM and ODM are welcomed.

3.Multistage Booster Water Pump for Pump Station Images

4.Multistage Booster Water Pump for Pump Station Specification

Material |

Cast iron and as customer's request |

Temperature |

Less than 150°C |

Flow rate | 3.75-300m3/h |

Head | 75-1000m |

Medium temperature | 0 ~170°C |

Operation pressure | ≤40 bars |

5.FAQ

①What is the applications?

Power Station,Industry Water Supply

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

- Q: What are the uses and precautions of magnetic pumps?

- 2, when the suction surface above the pump axis, before starting the valve can open the suction pipe, if the aspiration level below the pump axis, the pipeline to be equipped with bottom valve;3, the pump should be checked before use, the motor blade rotation to be flexible, no jam, no abnormal sound, the fasteners should be tightened;4 、 check whether the motor rotation direction is consistent with the magnetic pump steering mark;

- Q: What is a gear pump for?

- Internal wear of oil pumpOil pump parts wear will cause leakage. The large leakage area between the floating axle sleeve and the end face of the gear is the main part of the inner leakage. This part of the leakage accounted for about 50%~70% of the total leakage. The pump efficiency of the gear pump is much lower than the input power when the gear pump is worn and leaked. All of its losses are converted to heat energy, which will lead to overheating of the oil pump. If the joint plane is pressed, the movement of the floating axle sleeve will cause a little wear and tear when the work is in use, so that the farm tools can be lifted slowly or can not be improved, so the floating axle sleeves must be replaced or repaired.

- Q: What is the pump, how to classify, mainly used in where?

- Classification of pumpsAccording to the principle of division:1. displacement pumpDepending on the movement of the work parts, the volume of the work increases periodically and reduces the suction and discharge of the liquid, and the pressure of the liquid increases directly by the extrusion of the working partsAccording to the different movement of moving parts, it can be divided into two types: reciprocating pump and rotary pumpAccording to the structure of the moving parts are different: piston pump and piston pump; there are gear pumps, screw pumps, vane pumps and water ring pump

- Q: What is the principle of a turbopump?

- The working conditions of the turbine are different from those of the medium used, so the structure of the turbine is varied, but the basic working principle is similar. The most important component of a turbine is a rotating element (rotor or impeller) mounted on a turbine shaft with blades uniformly arranged along the circumference. The energy of the fluid is converted into kinetic energy in the flow through the nozzle, and when the fluid passes through the rotor, the fluid impacts the blade and drives the rotor to rotate, thus driving the turbine shaft to rotate. The turbine shaft drives the other machinery directly or through the transmission mechanism, and outputs mechanical work.

- Q: Water pump can not be pumped out, how to maintain water?

- Severe vibration of water pumpIt is possible that the rotor is unbalanced, or the coupling is not good, the bearing is worn and bent, and some parts may be loosened and broken. They can be adjusted, repaired, strengthened or replaced separately.

- Q: What are the application areas of pumps?

- Water pump has different uses, different transmission liquid medium, different flow, lift range, therefore, its structure form is not the same, the material is also different, summed up, can be roughly divided into:

- Q: I live on the 8 floor. Often there is no water. Life is very inconvenient. What kind of pump do I have to install? What should I pay attention to when I buy it? What's the pump for that brand? Should it be installed in that position?

- (8) check the suitability of the foundation and whether the size of the foundation corresponds to the size of the pump.(9) find the position of positive pump and motor, pump set and anchor bolt and the inlet and outlet flanges, to ensure that the flange torque of the pump conforms to the standard. Check the inlet and outlet piping before alignment. Make sure the weight of the inlet and outlet pipe does not exert force or torque on the pump. When looking for, should also pay attention to eliminate the pump rotor movement, so as to avoid the end gap error. If checked after the pump is working, it should be carried out under cold condition. It is important to draw attention to the fact that the pump set of the complete set of factory is only rough looking (checked with a ruler) when it is shipped. It may cause displacement when it is transported.

- Q: What is the pumping property of concrete?

- Pumpable concrete slump is generally greater than 160mm, the mortar content is too low, the maximum aggregate size of not more than 1/3 of the diameter of the pump pipe, sending process segregation, plugging in the pump.

- Q: Is the flow meter in front of the pump or after the pump?

- After the pump, the reasons are as follows, before the pump, you pump fluid through the pump will produce negative pressure in front of the pump, negative pressure on the flow of the life of the impact, the pump will not, Suzhou first Chi meter

- Q: Centrifugal pumps for normal operation, is it reasonable to install valves on their inlet lines? Why?

- Unreasonable, easy to produce throttling loss, pressure loss, pressure reduction, easy to cause cavitation

Send your message to us

Multistage Booster Water Pump for Pump Station

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords