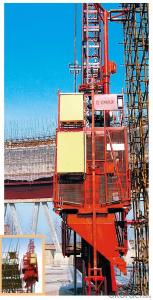

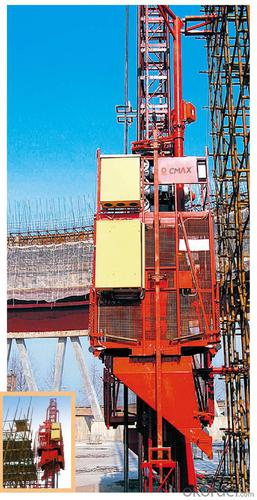

Multifunctional Construction Hoist /Material Hoist /Industrial Hoist /Lift /Elevator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Our SC Construction Hoist is an industrial engineering elevator driven with pinion and rack, used for vertical transportation of materials, people and other heavy items, applicable to highrise building construction, storehouse, port, dock, tower, chimney and so on.

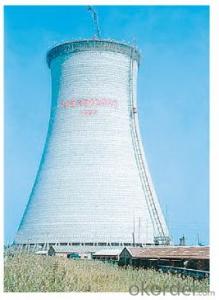

This hoist has multifunction of transporting people, steel bar, and concrete. Can be used in power station high chimney and cooling tower construction and so on. It can replace the old technique of transporting materials by huge jib crane and rope windlass, work easily and save a lot of equipments.

Features:

1. Over-sized car (10ft 6 in x 4ft 11 in) allows you to load 10-foot sheets of drywall with room to spare.

2. 3rd door on the side (10 ft wide) for even greater flexibility and easy loading in tight job site conditions.

3. Sturdy aluminum side panels help protect care against damage and the contractor against claims.

4. The car has anti-slip, water resistant, steel flooring with a patterned surface for additional occupant safety.

5. Cars have clear Lexan windows instead of wire mesh which protects occupants from debris, dust and weather--yet still provides excellent visibility.

6. Three motors provide direct drive instead of a counter weight system. Direct drive enables smooth operation and quicker and less expensive hoist climbing.

7. Optional heat and air conditioning for occupant comfort and protection against the elements.

8. Optional Automatic Rack Lubrication device drastically reduces required operator maintenance.

9. Long life bearings reduce service calls.

10. Most components of the hoist are either hot zinc dipped galvanized, tread plate aluminum or coated with a special three process industrial paint finish.

Specifications:

Remark: Recommended cage dimension (LXWXH): 2.0X1.0X2.5

- Q: Is it possible to utilize a building hoist for lifting materials during demolition projects?

- <p>While a building hoist is typically designed for construction purposes to lift materials and personnel, it is not advisable to use it for demolition work. Demolition involves hazardous conditions with falling debris and unstable structures, which can compromise the safety and integrity of the hoist. Instead, specialized equipment like wrecking balls, hydraulic shears, and cranes are more suitable for demolition tasks. These are engineered to handle the heavy loads and unpredictable conditions associated with breaking down structures safely.</p>

- Q: The user is inquiring about the possibility of purchasing a second-hand construction hoist.

- <p>Yes, you can buy a used building hoist. Many companies specialize in selling refurbished or used construction equipment, including building hoists. You can find them through online marketplaces, auction sites, or by contacting construction equipment dealers directly. It's important to inspect the hoist for any damages or wear and ensure it meets safety standards before purchase. Additionally, consider the hoist's age, maintenance history, and any warranties that might still be valid.</p>

- Q: This question asks for the method to determine the maximum weight a building hoist can safely lift.

- <p>To calculate the load capacity of a building hoist, you must consider several factors. First, refer to the manufacturer's specifications for the hoist model in question, as they will provide the maximum load capacity. Check the hoist's mechanical components, such as the motor, cables, and pulleys, to ensure they are in good condition and can support the intended load. Factor in the weight of the materials to be lifted, including any containers or attachments. Consider the hoist's speed and lifting height, as these can affect stability and safety. Always adhere to safety regulations and never exceed the manufacturer's specified load capacity to prevent accidents and equipment damage.</p>

- Q: This question asks for a list of various types of cables that are utilized in lifting equipment.

- <p>Lifting equipment employs several types of cables, each designed for specific purposes. The primary types include: 1. Wire ropes, which are the most common and are used for their strength and flexibility. 2. Chain slings, which are strong and durable but less flexible than wire ropes. 3. Synthetic slings, made from materials like nylon or polyester, offering lighter weight and resistance to chemicals. 4. Round slings, providing a smooth surface to protect loads from damage. 5. Wire rope slings, which are versatile and can be used in various configurations. 6. Aircraft cables, known for their high strength and resistance to corrosion. 7. Endless wire rope slings, which are used for heavy loads and offer a looped design. Each type of cable has its own set of advantages and is chosen based on the specific requirements of the lifting task.</p>

- Q: Is it permissible to use a building hoist for the purpose of lifting hazardous materials?

- <p>A building hoist is typically not designed for lifting dangerous materials. It is meant for the transportation of construction materials and personnel within a building. Lifting hazardous materials requires specialized equipment and procedures to ensure safety. Always refer to the manufacturer's guidelines and local regulations for the appropriate use of hoisting equipment and handling of dangerous materials.</p>

- Q: How many floors are built to use the construction elevator? With six floors?

- The construction elevator, the average layer height above 12 floors need to be used, the hoist machine is not to go up to use the construction elevator to send a person to carry a few light things upstairs.

- Q: Is it advisable to use personal lifting equipment without seeking professional advice first?

- <p>No, it is not advisable to use your own lifting equipment without consulting professionals first. Lifting operations can be hazardous and require specific knowledge and expertise to ensure safety. Professionals can assess the weight, stability, and appropriate lifting techniques required for your equipment. They can also provide guidance on safety regulations and the correct use of lifting gear, which is crucial to prevent accidents and injuries. Always consult with experts before undertaking any lifting tasks to ensure compliance with safety standards and to protect yourself and others.</p>

- Q: This question asks about frequent issues related to building hoists and seeks solutions for these problems.

- <p>Common problems with building hoists include mechanical failures, electrical issues, overloading, and safety malfunctions. Mechanical failures can be fixed by regular maintenance, lubrication, and replacement of worn parts. Electrical problems may require checking wiring, connections, and replacing faulty components. Overloading can be prevented by strictly adhering to the hoist's weight limit and using load indicators. Safety malfunctions, such as brake failure, require immediate attention and may involve replacing brake pads or overhauling the braking system. Always ensure that hoists are used according to the manufacturer's guidelines and are regularly inspected by qualified personnel to prevent accidents and ensure safe operation.</p>

- Q: There are differences between the construction elevator and the construction elevator

- The principle is different, the construction elevator operates in the litter box. The elevators are short for construction elevators, which are very high in the safety and performance of large facilities that can be used on the site. The construction elevator should be a dual-use lifting device.

- Q: This question asks if improper functioning or lack of maintenance in hydraulic cylinders can lead to damage.

- <p>Yes, hydraulic cylinders can cause significant damage if they malfunction or are not properly maintained. Malfunctions can lead to leaks, component failure, or even structural damage due to pressure surges. Lack of maintenance can cause wear and tear, leading to reduced efficiency and potential failure. Regular maintenance, including checking for leaks, ensuring proper lubrication, and replacing worn parts, is crucial to prevent damage and ensure the safe operation of hydraulic systems.</p>

Send your message to us

Multifunctional Construction Hoist /Material Hoist /Industrial Hoist /Lift /Elevator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords