Mini Construction Hoist /Material Hoist /Building Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

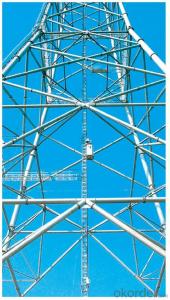

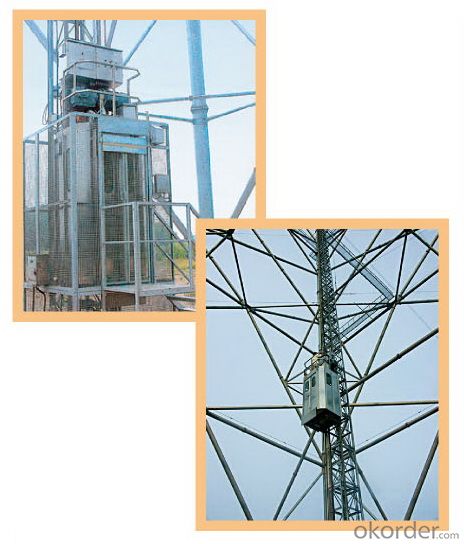

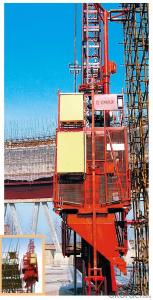

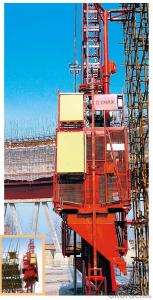

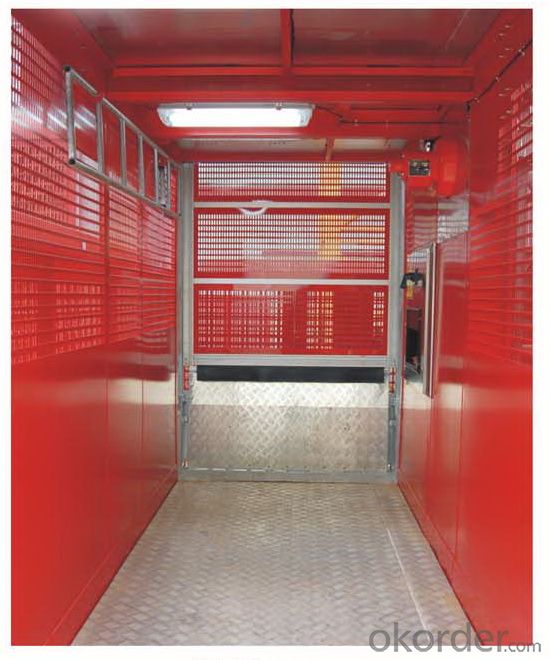

Construction hoist is commonly used on large scale construction projects, such as high-rise buildings. Also used by many other industries for full-time operations, to carry personnel, materials, and equipment quickly between the ground and higher floors, or between floors in the middle of a structure.

Features:

The mini building hoist is a minor vertical transportation machine. It is designed on the basis of Mesh Driving Principle of Pinion and Rack and mainly applied in industrial and civil construction, for tower crane, harbor machinery, power transmission tower, bridge, television tower, chimney, boiler, tunnel and so on, to transport people and materials.

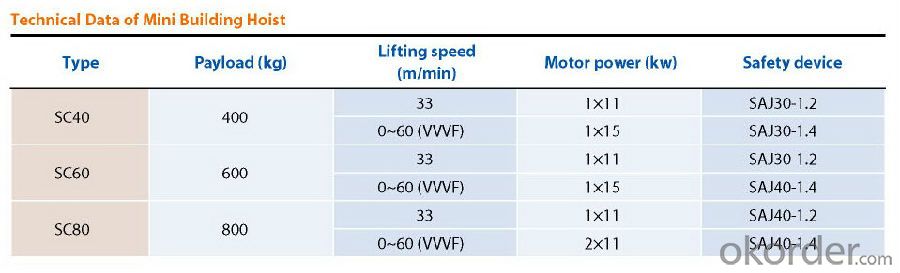

Specifications:

Remark:

1. Recommended cage dimension (LXWXH) (m): 1.0X0.75X2.2, 1.5X1.0X2.2 etc, we can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to your requirements.

3. The mast and the tie-in surface can adopt paint-spray, or hot galvanizeing processing.

- Q: This question asks for the proper usage guidelines for a building hoist, a mechanical device used in construction to lift materials.

- <p>To use a building hoist correctly, follow these steps: Ensure the hoist is inspected and certified for safe operation. Check all safety devices, including limit switches and emergency stops, are functioning. Securely attach the load to the hoist's hook, ensuring it's balanced and within weight limits. Never exceed the hoist's capacity. Operate the hoist with caution, avoiding sudden starts or stops. Keep the hoist area clear of people and obstacles. Use a tag line to guide the load if necessary. Always lower the hoist when not in use and secure it against wind or other forces. Regular maintenance and inspections are crucial to prevent accidents.</p>

- Q: Is there any violation of the law after the construction elevator is scrapped?

- Wire rope derrick type: 5 years Gear rack: 8 years After the accident, the person in charge will be unlucky

- Q: This question asks for a comparison between electric and manual lifting equipment, highlighting their distinct features and operational differences.

- <p>Electric lifting equipment, such as electric hoists and cranes, operates using electrical power and is designed for heavy-duty lifting and repetitive tasks. It offers high efficiency, ease of use, and often requires less physical effort from operators. On the other hand, manual lifting equipment, like levers, pulleys, and manual hoists, relies on human power and is typically used for lighter loads or in situations where electrical power is not available. Manual equipment is generally more portable and requires no power source, but it is slower and more labor-intensive. Electric equipment is more suitable for industrial settings, while manual equipment is often used in smaller-scale operations or for temporary tasks.</p>

- Q: Can a building hoist be utilized for the transportation of objects within and between buildings?

- <p>Yes, building hoists are specifically designed to move objects vertically within buildings. They are commonly used in construction to lift materials and equipment to different floors. Additionally, they can be employed to transport objects into and out of buildings, especially when access is limited or when heavy loads need to be moved over short vertical distances. However, it's important to adhere to safety guidelines and regulations when operating a building hoist to ensure the secure and efficient movement of objects.</p>

- Q: This question asks about the process of installing a new building hoist, which is a piece of equipment used in construction to lift materials and personnel.

- <p>Installing a new building hoist involves several steps: 1) Site preparation, ensuring the area is clear and level. 2) Unpacking and inspecting the hoist components for any damage. 3) Assembling the hoist tower, starting with the base and working upwards. 4) Installing the drive unit and cable system. 5) Attaching the counterweight and safety devices. 6) Rigging the hoist to the building structure for stability. 7) Conducting a thorough inspection and testing the hoist for safety and functionality. 8) Obtaining any necessary permits and approvals. 9) Training operators on the safe use of the hoist. It's crucial to follow the manufacturer's instructions and local regulations when installing a building hoist.</p>

- Q: How many kw is the sc construction elevator

- The construction elevator sc200/200 is rated at 63 kw power, and the power consumption is greater.

- Q: Is it possible to replace an electric control panel with a manual lever in a lifting system?

- <p>While it is theoretically possible to use a manual lever as a substitute for an electric control panel in a lifting system, it is not advisable. Manual levers lack the precision, safety features, and control capabilities of electric control panels. They also cannot provide the same level of feedback or automation. Electric control panels are designed to ensure safe and efficient operation, with features like emergency stop buttons, overload protection, and remote monitoring. Manual levers can pose safety risks and may not meet the operational requirements of modern lifting systems.</p>

- Q: This question asks for the procedure to safely lower an object after it has been lifted using a building hoist.

- <p>To safely lower an object after using a building hoist, ensure that the area below is clear of people and obstacles. Slowly release the hoist's brake or control mechanism, allowing the object to descend gradually. Keep a steady hand on the controls to maintain a controlled descent. Monitor the object's position and communicate with ground personnel if necessary. Ensure all safety hooks and attachments are secure until the object reaches the ground. Once the object is safely on the ground, secure it and disconnect it from the hoist. Always follow the manufacturer's guidelines and safety protocols for the specific hoist being used.</p>

- Q: This question asks for the steps or methods to fix a malfunctioning building hoist.

- <p>Repairing a broken building hoist requires a systematic approach. First, ensure the hoist is powered off and disconnected from any power source to ensure safety. Identify the specific issue by conducting a visual inspection and possibly consulting the hoist's manual or a professional. Common repairs include fixing mechanical parts like gears, chains, or cables, or addressing electrical issues like faulty wiring or motor problems. If the hoist's control system is malfunctioning, it may require recalibration or replacement of components. In some cases, worn or damaged parts need to be replaced. Always follow the manufacturer's guidelines and safety protocols. For complex repairs, it's best to consult with a professional hoist technician to avoid further damage or safety hazards.</p>

- Q: Is it possible to utilize building hoists for the transportation of materials and equipment within construction sites?

- <p>Yes, building hoists are commonly used in construction sites to move materials and equipment. They are designed to lift and lower heavy loads vertically, making them ideal for transporting construction materials, tools, and equipment between different floors or levels of a building under construction. This equipment significantly enhances efficiency and safety on construction sites by reducing manual labor and the risk of accidents associated with manual handling of heavy items.</p>

Send your message to us

Mini Construction Hoist /Material Hoist /Building Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords