Most Popular FRP Roofing Sheet Making Machine with Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

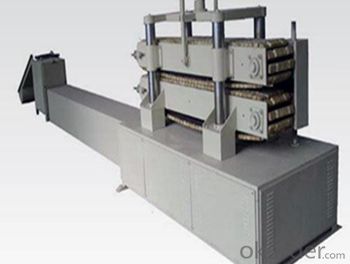

Most Popular FRP Roofing Sheet Making Machine with Good Price

Product Description:

This production line is able to produce lighting sheet, color sheet, common plane sheet and gel coat sheet(make on demand).

Product Features:

1. Double-layer layout structure, lower the requirement on length of plant.

2. Impregnation platform have multi-line independent temperature control, temperature control is more precise,able to adapt the changing of ambient temperature,speed of impregnation is fast, speed of production is improved effectively.

3. Special cross cutting machine and good synchronization performance make cutting accurately.

4. All the machine parts adopt international standard steel make machine with high stability.

5. System failure can be automatically alarmed and show fault point. Make maintenance easily

6. Particular parts adopt special purpose wire, durable in use.

7. Size and layout of machine can be made according to customer requirements.

Product Parameter:

Name | Most Popular FRP Roofing Sheet Making Machine with Good Price |

Brand | CMAX |

Weight | 8 Tons |

Dimension(L*W*H) | 6800*1500*1700 |

Power | 25kw |

Voltage | 420V 50HZ |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Sheet |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Hebei, China (Mainland) |

Color | Customizable |

Warranty | One Year |

Time of Delivery | 30-45 days |

Product Pictures:

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be 30-45 days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

- Q: I am engaged in the plastic processing industry, mainly for ABS and PP through chemical agent for processing, will this be harmful to the body?

- Alkyl tea sulfonate (ABS) can not only poison the body, but also promote carcinogenic effects of carcinogens. Recently, it has been found that ABS also has the risk of teratogenic changes.Polypropylene (PP) itself is non-toxic, but I do not know what you say powder ingredients, if there are plasticizers, masterbatch and the like, there is a certain toxicity.In the production of ABS containing detergent factory, should pay attention to do a good job of environmental protection, adopt cleaner type production process, in the production process to be closed, to reduce the concentration of ABS in the air of workplace and workers to do protective measures. Some large metal washing plants, paper mills, leather factories, food factories, etc., should be used in the use of mechanized operation, reduce manual operation, prevent long time direct contact with the skin. Pregnant women should change jobs appropriately so as not to influence the next generation. The waste water discharged by the factory should be discharged after the sewage treatment has been purified to meet the national discharge standard so as to ensure that our groundwater resources are free from pollution.

- Q: Are the fragrance of poisonous substances poisonous in plastic products?

- Poisonous, smelling, and dying so fast, so many people with mechanical hand out, we repair the manufacture of mechanical hand

- Q: What are the plastic products used in heavy trucks, and how do they form?

- 5 、 blow molding, blow molding, used in thermoplastics. This is the molten plastic in the mold, under the compressed air pressure, the plastic blow up, close to the mold surface. But, by punching and demoulding products. The production of various types of hollow containers, also can produce thin film, and thin. The land, forming a plurality of heating heating molding thermoplastic. This is the plastic sheet is heated into elastic state, and then subjected to pressure to attach to the mold molding. Multi disc products. Production of dishware, paint, plastic foam molding foaming foot add foaming agent, foaming and foam injection mould making, solidifying products. The utility model is used for making cushioning packages for precise instruments and meters. It is used for molding, molding the thermosetting plastic. This is a powder, flake or granular thermosetting resins and additives, directly close mold in mold, heating, pressurizing, plastic and liquefaction, chemical reaction and curing, cooling after the products. Production of lumber and electrical appliances, machinery parts, 9, casting molding casting molding for jade. The thermosetting plastic molding powder is placed in the material barrel heating to heat plasticizing, pressed into the mold, and the product complete solidification under pressure. Complex products production needs. A metal block 0, casting casting for forming solid thermal plastic. It will plasticized thermosetting plastic injection mould, curing under normal pressure, cooling and demoulding to obtain the products. The production of electronic, electrical and metal insert element

- Q: What kind of equipment do household workshops need to process plastic products? Can you make money? What are the sales channels?

- The biggest investment is the injection molding machine, as well as three-phase power, it is best to understand the machinery will repair the mold, there is a stable processing order, you do not need to sell it!

- Q: What are the plastic products stocks?

- Provide land, property, equipment, vehicle rental services.TS: domestic major enterprises to focus Plitt production of automotive modified plastics products, key high-tech enterprise of national torch plan. Currently has five series of more than 300 varieties, with an annual output of 50 thousand tons of production capacity, production of automotive modified plastics in the domestic enterprises in the top, the yield of modified ABS, PC/ABS alloy products ranked first, the yield of modified PP products are also in the forefront. The company provides services for automobile manufacturing, household appliances, electronic information and other enterprises, specializing in high performance plastic composite materials research, production, sales and service, is one of the industry earlier for the automotive industry the most complete enterprise qualification.

- Q: The processing of plastic bottles

- Plastic bottle molding is the process of making final plastics from polymers made from synthetic resin manufacturing plants. The processing method (usually called plastic processing) (including compression molding), extrusion (extrusion) and injection molding (injection molding), blow molding (blow molding), rolling, to go through a total pressure plastic, extrusion, injection molding, blow molding, foam molding, calendering, etc. six processes.1 、 pressing and moldingPress molding is also known as molding or pressing, and molding is mainly used for molding thermosetting resins such as phenolic resin, urea formaldehyde resin and unsaturated polyester resin.2. ExtrusionExtrusion, also known as extrusion molding, is the use of extruders (extruders) to heat the resin continuously through the mold extrusion of the desired shape of the product. Extrusion is sometimes also used in the forming of thermosetting plastics and can be used in the moulding of foamed plastics. The advantage of extrusion is that it can extrude various shapes of products. The production efficiency is high, it can be automated and continuous production. The disadvantage is that thermosetting plastics can not be widely used in this process, and the size of products is prone to deviation.3, injection moldingInjection molding is also called injection molding. Injection molding is the use of injection molding machines (or injection machines) to inject thermoplastic melts at high pressure into the mold and to cool and cure the products. Injection molding can also be used for moulding thermosetting plastics and foams. Injection molding has the advantages of fast production, high efficiency, automatic operation, and complicated shape. It is especially suitable for mass production. The disadvantage is that the equipment and mold cost is high, the injection molding machine cleaning more difficult.

- Q: What do you understand in the early stage and how much equipment are needed for the preparation?. Thank you

- Then don't do it. Baidu can't support you in such a big deal. Because big bosses rarely disclose business experience on Baidu - find a reliable master or technician and learn from it

- Q: now have no market quite suck me how to go find the market ask predecessors and friends hope that they can point out a way to thank you

- The reason why there is no sales price or quality problems?AskNeither price is lower than others, quality can be problem without production licenseChasing the answerDoes it depend on relationships?

- Q: What kind of equipment do you need for plastic basin processing? How much is it?

- Injection molding machine manufacturers are different, the degree of automation is different, the price is different, two injection molding machine about five hundred thousand yuan.

- Q: What kind of equipment do you need for the food market? How much would you like to invest? What about the profit?

- The first said equipment 1 blowing machine 2 printing machine 3 bag making machine 4 mill material if want to make your own words also need about 27000 granulating machine, film blowing machine, printing machine if printing a color around 10 thousand, if 2 more than 20000 more than 20000 color printing, bag making machine semi-automatic, fully automatic ranging from 4-5 million, 3500 mill more than 20000, granulator, raw materials are polyethylene, if the price of raw materials is a new material price 11000 tons, if it is recycled about 7000 of us production of complete sets of equipment

Send your message to us

Most Popular FRP Roofing Sheet Making Machine with Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords