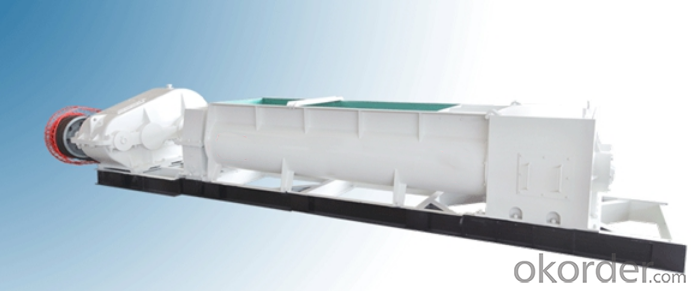

Mixing Equipment---Double-Shaft Mixing Extruder(Multiple models)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stirring Diameter(mm):480~550

Production Capacity(m³/h):50~100

Product description:

This type of equipment has good rigidity, large capacity, long stirring time, and good stirring effect; it ensures uniform stirring of raw materials and water, low energy consumption and high efficiency; It is suitable for stirring various solid and powdery raw materials, especially suitable for the Brick and Tile Industries with high production capacity requirements. It is suitable for stirring and mixing of raw materials such as clay, coal gangue, shale, fly ash and tailings.

- Q: Where can a concrete mixer be used?

- Construction sites, Bridges, roads and so on are indispensable

- Q: How long will it take for a concrete mixer to beat ten square?

- The first set of 10 square is 120, and the first set of 2 squares is calculated from the above, and the time is saved by 4 minutes in 4 minutes, the average of 15 minutes is calculated by C50 high performance concrete. If it's a C20 no water reducer, just five minutes!

- Q: A concrete mixer can last for years

- The concrete mixer's life span is different from that of the car, which can be referenced in several ways: One, the manufacturer that produces, the domestic that imports, the life span is different Second, the production of domestic big brand manufacturer and small factory produce, the life span is different The type of mixer is different (simple, small, medium, large) Four, the frequency that USES is different, life is different The period of maintenance is different, different life span Manufacturer general guarantee a year, if maintenance is good, that is spent long, have no specific numerical value can answer

- Q: How to safely use concrete mixer

- Action steps for concrete mixers: 1, switch the function switch from the column to "automatic" position, press the start switch on the controller, and the whole operation will operate automatically. After the whole process is finished, it will stop automatically, and in the running project, if it is necessary to stop, press the stop button and then restart. After the start button is pressed, the display begins to show time, slow, sand, fast, stop, fast, and run the light on time. When automatic control, all the switches must be allocated to the stop position.

- Q: How many square concrete can be produced in an hour of concrete mixer

- The blender can produce 50L concrete at a time, which is 0.05 square concrete. The blender is about 20 times before the concrete is produced. Mixer, it is a kind of with the blade shaft rotating in the cylinder or tank, will a variety of raw materials mixing, make it become a kind of mixture or machine suitable for consistency. The blender is divided into several kinds, such as strong mixing machine, single-sleeper shaft mixer, two-sleeper shaft mixer and so on. Note: mixers and automatic feeding machines must be cleaned, especially in winter, which can prolong life. A blender is a mixer because the mixing machine is commonly used to mix and stir all kinds of dry mortar

- Q: What is the difference between a concrete mixer and a mortar mixer

- In power, power, and volume, concrete mixers search large

- Q: Is the concrete mixer and mortar mixer a machine

- The mortar mixer is the machine which mixes the cement, the sand and the aggregate with the water and mixed the mortar. It consists mainly of mixing, loading and unloading mechanism, water supply system, original motive, transmission mechanism, frame and supporting device. Mortar mixer equipment can meet the performance requirements of dry mortar, dry material, adhesive powder production needs, such as: putty powder, powder coating, masonry mortar, plaster mortar, insulation mortar, decorative mortar needed by the system and so on all kinds of dry powder mortar; And it has many advantages such as small area, little investment, quick results and easy operation. Working principle: when mixed machine work, inside the machine material subjected to two opposite direction of the rotor, with complex movement, the blades to drive the material aspect counterclockwise along the machine slot wall, on the one hand, drive material turning around, overlapping the two rotor shape floating zone, within the region, regardless of the shape of the material, size, and density, can make material floating instant weightlessness, which makes the material in the machine groove omni-directional continuous loop turn staggered shear each other, so as to achieve the effect of rapid mixing soft.

- Q: What is the type of concrete mixer?

- Concrete mixer type mainly has: JZC250, JZC350, JZC500, JZM350, JZM500, JZM750, JDC350, JDC500, JDY350, JDY500 etc., including JZM is friction type drum mixer, JDY/JDC for single horizontal-axis forced concrete mixer, JZC fell for type concrete mixer drum.

- Q: How does a concrete mixer operate

- If the machine is relatively new, the button will have, it's going to go up, go down, automatically add water, add water by hand, mix it up, mix it up, stop, vibrate

- Q: What is the difference between a concrete mixer, a JL type and a JW type?

- The jw-200 type mixer consists mainly of the main parts, such as the platform car, the motor, the gearbox, the feeding mechanism, the mixing mechanism and the feeding trough. After the electric start-up, the process of feeding, stirring and discharging is carried out through the transmission such as the triangle belt, the coupler and the worm gear reducer. The concrete mixer is small and suitable for underground.

Send your message to us

Mixing Equipment---Double-Shaft Mixing Extruder(Multiple models)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.