Mirafi 180n Filament Geotextile - The Best Filament Spunbond Needle Punched Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

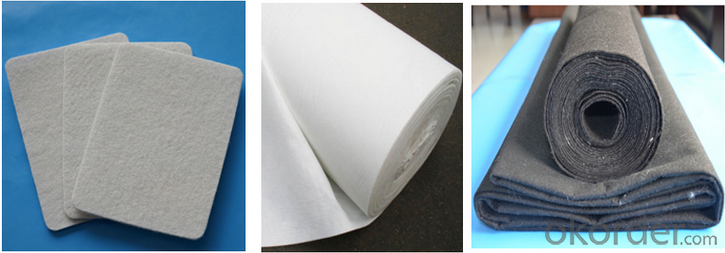

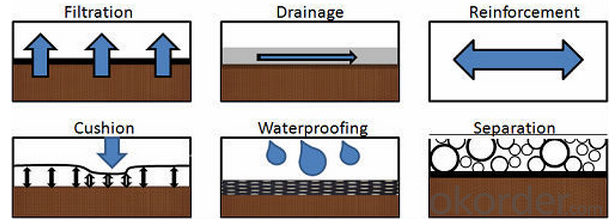

Geotextiles are permeable nonwoven fabrics used to separate,filter,reinforce, protect or drainage.Geotextiles allow filtration or separation of granular layers in roads and rail applications,used to protect membranes in landfill applications,used in coastal defence applications and used in landscaping to protect surfaces and structures from weeds and root growth.

Geotextiles are available as woven and non-woven .As liner protection, against physical damage, the non wovens are normally the answer.They are made up of fibers of polyester or polypropylene in random directions and punched together by needles during the manufacturing process.Geotextiles are commonly used to separate layers like clay and drainage and to protect liner from damage.

Product Details

Features:

Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction

Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

Manufactured using a randomly orientated web to provide completely isotropic properties,ensuring that high strength is not limited to a single direction.

Excellent uniformity with high permeability and low pore size for soil filtration.

Supplied to a maximum width of 8.0 meters,ensuring minimum waste over large construction areas.

100% polypropylene or polyester staple fibers ,needle punched and random network formation.

UV and rot resistant and biological degradation resistant.

Majority Process:

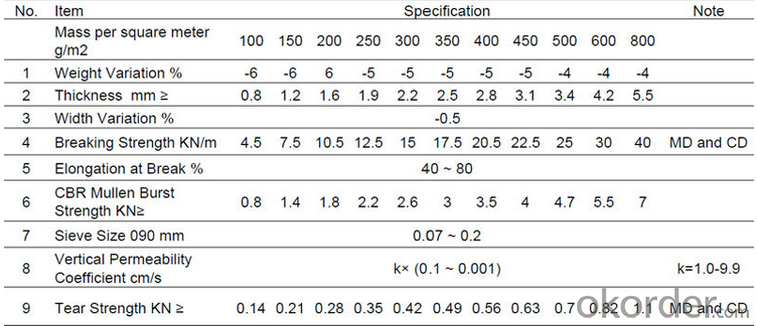

Specific Data:

FAQ:

1. How to order your geotextile?

a). Tensile strength in warp & weft direction

b). gram per meter

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

3. Delivery time

a) 19-25 days after received your deposit .

4. What is MOQ ?

a) 2000 m2 as MOQ , we can also produce sample for you .

- Q: What are the advantages of using geotextiles in storm surge protection systems?

- Geotextiles offer several advantages in storm surge protection systems. Firstly, they can effectively control erosion by stabilizing soil and preventing it from being washed away during heavy storms. Secondly, geotextiles act as a filter by allowing water to pass through while retaining sediment, thus reducing the risk of clogging drainage systems. Additionally, they provide reinforcement to structures, such as retaining walls or revetments, enhancing their stability and durability against wave action. Moreover, geotextiles are lightweight and easy to install, making them a cost-effective solution for storm surge protection.

- Q: How do geotextiles help in preventing sinkhole formation?

- Geotextiles help in preventing sinkhole formation by providing a stable base for the soil and reducing the risk of erosion. They act as a barrier to prevent the movement of soil particles, thus preventing the formation of voids or cavities that can lead to sinkholes. Additionally, geotextiles can improve the overall structural integrity of the soil, enhancing its load-bearing capacity and minimizing the potential for sinkhole development.

- Q: Can geotextiles be used for reinforcement of canal banks?

- Yes, geotextiles can be used for reinforcement of canal banks. Geotextiles provide stability and erosion control, helping to prevent soil erosion and maintain the integrity of canal banks. They can be used to reinforce the soil, distribute loads, and provide filtration and drainage, making them a suitable solution for reinforcing canal banks.

- Q: Can geotextiles be used in coastal erosion control in beach nourishment projects?

- Yes, geotextiles can be used in coastal erosion control in beach nourishment projects. Geotextiles are commonly used as a protective barrier to prevent erosion and stabilize the shoreline. They can be placed under the sand or gravel layer in beach nourishment projects to enhance the stability and longevity of the beach, reducing the impact of wave action and promoting sediment retention.

- Q: What are the advantages of using geotextiles in wetland restoration projects?

- There are several advantages of using geotextiles in wetland restoration projects. Firstly, geotextiles provide effective erosion control by stabilizing the soil and preventing it from washing away during heavy rainfall or flooding. This helps in maintaining the wetland's structure and preventing further degradation. Secondly, geotextiles act as a barrier, preventing the migration of harmful substances such as pollutants or excess nutrients from adjacent areas into the wetland, thus protecting its ecological integrity. Additionally, geotextiles can enhance vegetation growth by retaining moisture in the soil, promoting root development, and preventing weed growth. This ultimately contributes to the overall success of wetland restoration efforts.

- Q: How to apply the geotextile of the retaining wall filter

- I am specializing in the production of geotechnical materials, wish smooth

- Q: What is the place of attention for the laying of geotextiles?

- (1) the use of the use of buried type: cover the thickness should not be less than 30cm (2) refurbishment system should be: cushion, impermeable layer, transition layer, protective layer composition. (3) soil to be solid, to avoid uneven subsidence, cracks, anti-seepage within the turf, root to clear. And the surface of the membrane with a small particle size of sand or clay as a protective layer. (4) laying the geomembrane do not pull too tight, both ends of the soil into the corrugated part of the soil is better, especially with the rigid material anchoring, should leave a certain amount of expansion and contraction. (5) construction, should avoid stones,

- Q: What is the difference between woven and non-woven geotextiles?

- Woven geotextiles are made by interlacing yarns or fibers together, creating a strong and durable fabric. They have a high tensile strength and are commonly used for applications that require high load-bearing capacity, such as stabilizing soil or preventing erosion. Non-woven geotextiles, on the other hand, are made by bonding fibers together using heat, chemicals, or mechanical processes. They are generally less strong and more flexible than woven geotextiles. Non-woven geotextiles are often used for filtration, separation, or drainage purposes, where their permeability and ability to retain fine particles are important factors.

- Q: Can geotextiles be used for reinforcement of underground tunnels?

- Yes, geotextiles can indeed be used for the reinforcement of underground tunnels. Geotextiles are flexible, permeable materials that can provide support, stability, and prevent soil erosion in various civil engineering applications, including tunnel construction. They can be placed to reinforce the surrounding soil and prevent movement or collapse, enhancing the structural integrity of the tunnel. Additionally, geotextiles can also act as a drainage layer, allowing water to flow through while minimizing soil saturation, which is crucial for long-term tunnel stability.

- Q: Can geotextiles be used in erosion control in river channel stabilization?

- Yes, geotextiles can be used in erosion control in river channel stabilization. They are commonly used to prevent soil erosion and stabilize river banks by acting as a barrier that allows water to pass through while retaining the soil particles. Geotextiles can effectively control erosion and provide long-term stability to river channels.

Send your message to us

Mirafi 180n Filament Geotextile - The Best Filament Spunbond Needle Punched Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords