Ceramic Fiber Board for Wall Insulation Mineral Wool

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

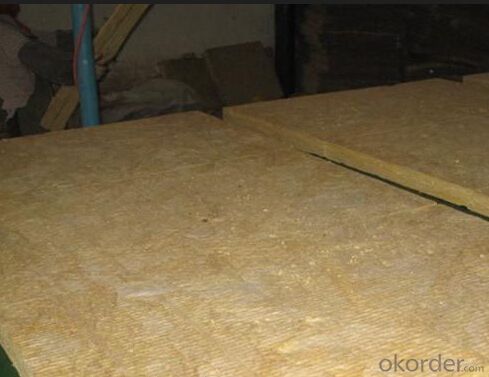

rockwool fiber,rock wool board,mineral wool for wall insulation

1.rockwool

2.fireproof

3.soundproof

4.waterproof

duct Description

Professional Manufacture.

widely used for insulation/sound absorption of the wall and ceiling

use basalt as raw material

Rock wool,mineral wool,rockwool board for building construction wall thermal insulation

1. Standard specifications as follows:

Rock wool felt / Rock wool roll

Density : 60--120kgs/m3

Thickness 50mm-150mm

Wide:600mm,

Length:3-5m

Aluminum foil and metal mesh are able to be stick on the surface.

2. Features:

1.energy conservation

2.excellent heat preservation and thermal insulation.

3.fire proof. it is made from natural rocks and it is non-combustible material.

4.physically and chemically stable, aging resistant and consistent thermal performance.

5.niose absorption.

6.easy handing and installation

3. Packaging:

Take advanced Vacuum compress technology

1. Normal standard woven bags

2. Heat contraction sealed

4. Technical Parameters

performance | index |

slag ball content (granule diameter) 0.25mm).% | 12.0 |

average value of fiber,µm | 7.0 |

density allowable deviation ,% | +15.-15 |

thermal conductivity(average temperature70 ±52),W/(m.k) | 0.044 |

shrinkage temperature of heat load(60kg/m3) , | 600 |

water content,% | 0.5 |

combustibility | Grade A incombustible |

organic content,% | 4.0 |

moisture resistivity(moisture-proof rock wool board),% | 98 |

water absorption (moisture-proof rock wool board),% | 5 |

All the performance indexes of product are in line with the standard of ASTM C 795, JIS A 9504 and etc.

Technical parameters of facings

facing name | sandwich aluminum foil facing | fire-retardant sandwich aluminum foil facing | polypropylene plastic facing |

facing No. | F-1 | F-2 | F-3 |

appearance | silver | silver | silver /white |

structure | four-layer composite structure | four-layer composite structure | four-layer composite structure |

aluminum foil surface | aluminum foil surface | polypropylene surface | |

bonder layer | bonder layer | bonder layer | |

three-directional fiber layer | three-directional fiber layer | three-directional fiber layer | |

brown paper layer | brown paper layer | polypropylene surface |

The field of usage of rock wool

The product is widely used for the heat insulation and sound absorption in building field and heat preservation of pipes, wires and so on. We make much progress in producding products for make it good for human. Thus this product has excellent properties, such as elasticity, pliability, handle tenderness, little soft flocks.

FACTORY:

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: What are the standards for ceramic fiber boards?

- The existing ceramic fiber board has broken through the age of fear of water, and the newly developed hydrophobic ceramic fiber board has the characteristics of normal working under the water environment.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Ceramic fiber boardCeramic fiber board product categories:1260 standard ceramic fiber board sygx-264 1260 high purity ceramic fiber board sygx-3641400 zirconium ceramic fiber board sygx-564 1400 high alumina ceramic fiber fire plate sygx-464D1400 zirconium ceramic fiber fire baffle sygx-564D

- Q: What are the sound-absorbing fiber boards?

- Sound-absorbing material:1, itself has sound-absorbing properties, porous fiber material.2, does not have sound-absorbing material, but processed into sound absorption structure.Common sound-absorbing materials are: polyester fiber sound-absorbing board, trough wood sound absorption board, hole wood sound-absorbing board, recycled wood sound-absorbing board, the latest is Dr. sound, high temperature ceramic sound-absorbing board, a fire prevention, water quality, hard environmental protection

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board, also known as aluminum silicate or refractory fiber, including ceramic fiber blanket, ceramic fiber, ceramic fiber fireproof plate (plate).

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- The biggest difference between the two is that:1, the coefficient of thermal conductivity is different, the nano ceramic plate is about three times of the ordinary ceramic fiber board2, temperature class is not the same, nano ceramic board maximum temperature of 1050 degrees, ceramic fiber board should be 1400 degrees temperature.3, the range of applications is different. Nano ceramic plate is mainly used in high, fine and sharp technical fields, and has strict requirements on thermal conductivity. Ceramic fiber boards are widely used and can be used wherever there is flame or temperature.

- Q: What are the uses of ceramic fiber boards?

- The ceramic fiber board, also called aluminum silicate fiber board or refractory fiber board, is divided into five grades according to the temperature grade:Fire dragon type ceramic fiber board HLGX-164Fire dragon standard ceramic fiber board HLGX-264Fire dragon high purity ceramic fiber board HLGX-364The dragon of high alumina ceramic fiber board HLGX-464Fire dragon contains zirconium type ceramic fiber board HLGX-564

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Distinguishing.Ceramic silicon fiber board by long fiber silica, clay, talc, glaze etc. after 1150 degrees high temperature sintering, twenty-first Century revolutionary high-tech building materials. Characteristics: flexibility, high toughness, high strength, anti wind pressure; with homogeneous magnetized light ceramic surface, disposable, pores, anti pollution, is not easy to dust, mildew, antibacterial, deodorant, anti slip, no static, not fear of chemical erosion, such as acid, alkali, or even sulfate; fire, smoke, high temperature resistance, easy processing, cutting a hole.

Send your message to us

Ceramic Fiber Board for Wall Insulation Mineral Wool

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords