Mill finished aluminium sheet wih high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Plain Aluminum Coil Sheet Description:

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment

2.Main Features of Plain Aluminum Coil Sheet :

Reasonable and stable chemical composition

Accurate tolerance

Nice mechanical property

Standards: EN, ASTM and EN

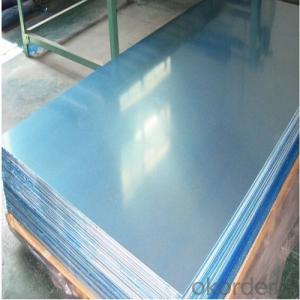

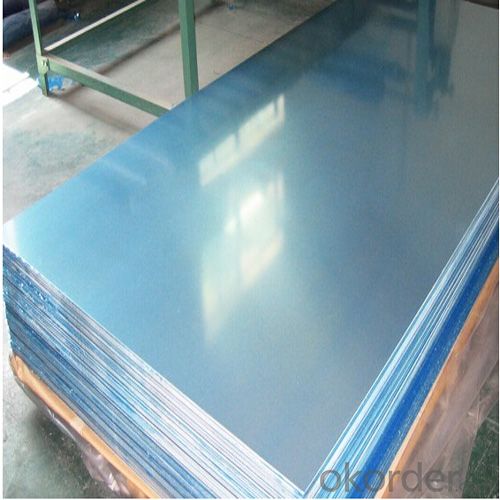

3.Plain Aluminum Coil Sheet Images:

4. Plain Aluminum Coil Sheet Specification:

| Description | Application | Feature | |

| 1000 SERIES | 1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. | Utensil, decoration, Reflecting plate, printing plate, heatproof plate,cookware | Easy to process and weld,resistant to rust,high,conductibility of electricity and heat,low strength |

| 3000 SERIES | 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment | Utensil(F/P, inside of rice cooker), aluminum can,material for interior and exterior of building,chemical equipment,Cellular Phone | 20% higher strength than the 1100 series, easily welded and brazed, good antirust,ability Non-heat treatable |

| 5000 SERIES | 5xxx series representatives 5052 5005 5083,5754. The 5000 series aluminum alloy aluminum belong to the more commonly used series, the main elements for magnesium, with magnesium in the amount between 3-5%. And can be called aluminum magnesium alloy. Key features for low density, high tensile strength, elongation rate is high. In the same area under the weight of the magnesium alloy aluminum less than other series. | Ship board heatproof apparatus, material for interior and exterior of building, Parts of Electronic tools.Automobile Components | Excellent corrosion resistance andweld ability together with Easy to process and weld and superior hardness &heatproof Can be anodized for increased corrosion resistance |

| 6000 SERIES | 6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications. | IT equipment & facility, Mould material, motor material, automatic line, machine & plant etc | Easy to process , good corrosion resistance, high toughness and processed without distortion after heat-treatable, superior surface treatment |

| 7000 SERIES | 7000 aluminum alloy is another common alloy, wide variety. It contains zinc and magnesium. The best strength in the common aluminum alloy is 7075 alloy, but it can't be welded, and its corrosion resistance is rather poor, many manufacturing parts with CNC cutting is 7075 alloy. | The aerospace industry & High strength accessories | 7000 series is high tensile to process with special alloy |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What are the different surface finishes available for aluminum sheet?

- There are several surface finishes available for aluminum sheet, including mill finish, brushed finish, anodized finish, and painted finish.

- Q: As for graphite and aluminum sheet, which one has a better thermal conductivity?

- aluminum sheet

- Q: Can the aluminum sheets be used for manufacturing electrical connectors?

- Yes, aluminum sheets can be used for manufacturing electrical connectors. Aluminum is a good conductor of electricity and is commonly used in the production of electrical connectors due to its lightweight, corrosion resistance, and cost-effectiveness.

- Q: Are aluminum sheets suitable for soundproofing applications?

- Yes, aluminum sheets can be suitable for soundproofing applications. Aluminum has good sound-blocking properties and can help reduce noise transmission when used in soundproofing applications. It is a lightweight material that can be easily installed as barriers or panels to create a sound barrier between different areas or to isolate specific equipment or machinery. Additionally, aluminum sheets can be used in combination with other soundproofing materials, such as foam or rubber, to enhance their soundproofing capabilities. However, it is important to note that the thickness and density of the aluminum sheets will play a significant role in determining their effectiveness for soundproofing. Thicker and denser aluminum sheets will provide better sound insulation compared to thinner ones. Additionally, other factors such as the design, construction, and installation of the soundproofing system will also impact its overall effectiveness in reducing noise.

- Q: Can the aluminum sheets be used for manufacturing audio amplifier cases?

- Certainly, audio amplifier cases can be manufactured using aluminum sheets. The utilization of aluminum as casing material in audio equipment is highly favored owing to its remarkable combination of lightweight and resilient characteristics. It offers exceptional heat dispersion, a critical aspect for audio amplifiers that generate heat while in operation. Additionally, aluminum can be effortlessly machined and shaped into diverse forms, facilitating customization and aesthetic considerations in the design of the amplifier case. In conclusion, aluminum sheets are a fitting choice of material for the production of audio amplifier cases.

- Q: Are aluminum sheets suitable for food processing conveyor systems?

- Yes, aluminum sheets are suitable for food processing conveyor systems. Aluminum is a lightweight and durable material that is resistant to corrosion and can withstand extreme temperatures. It is also non-toxic and does not react with food, making it a safe choice for conveying food products. Additionally, aluminum sheets are easy to clean and maintain, making them an ideal option for food processing conveyor systems.

- Q: Can aluminum sheets be textured for grip?

- Indeed, grip can be achieved through texturing aluminum sheets. Numerous techniques exist to impart texture onto aluminum sheets, including embossing, etching, and the application of a non-slip coating. By undergoing these processes, patterns, grooves, or raised bumps can be added to the sheet's surface, heightening its grip and rendering it suitable for situations where slip resistance holds significance. The textured surface amplifies the friction between the sheet and any object it comes into contact with, thereby delivering a secure grip, even in damp or slippery circumstances.

- Q: My mother has this idea that when her boyfriend puts coals from the wood stove in aluminum containers to warm the house that inhaling the fumes can cause Alzheimer's disease later in life. I am just curious about the truth of it.

- Aluminum does not, in any way, cause Alzheimers. More than 15 years ago, researchers identified higher quantities of aluminum in the brains of those with Alzheimers and even autism. It is the result of the blood-brain barrier being broken. In other words, it is a result, not a cause. Alzheimer's is currently believed to be caused by a virus as well as arterial changes in those who have diabetes (I just learned this one from my doctor last week). In other words, it is multicausal, but very likely associated with a virus. All that said, burning wood can increase your risk of respiratory problems and will make current respiratory problems worse. It is mostly problematic for children though.

- Q: How are aluminum sheets measured and specified?

- Aluminum sheets are typically measured and specified based on their thickness, width, and length. The thickness is commonly referred to as the gauge, and it is measured in inches or millimeters. The sheet's width and length are also specified in either inches or millimeters. To measure the thickness of an aluminum sheet, a gauge is used. The gauge is a standardized measurement tool that determines the sheet's thickness. The lower the gauge number, the thicker the sheet. For example, a 10-gauge aluminum sheet is thicker than a 16-gauge sheet. The width and length of an aluminum sheet are typically measured in inches or millimeters. The width refers to the horizontal measurement of the sheet, while the length refers to the vertical measurement. These dimensions are crucial in determining the sheet's size and suitability for specific applications. In addition to the gauge, width, and length, aluminum sheets may also be specified based on their alloy composition or temper. The alloy composition indicates the specific combination of metals present in the sheet, such as aluminum-magnesium, aluminum-zinc, or aluminum-copper alloys. The temper refers to the heat treatment process the sheet has undergone, which affects its mechanical properties, such as hardness and flexibility. Overall, aluminum sheets are measured and specified by their thickness (gauge), width, and length. These measurements, along with additional specifications like alloy composition and temper, help ensure the appropriate selection and use of aluminum sheets for various applications in industries such as construction, automotive, aerospace, and more.

- Q: Can 101 aluminum sheets be anodized in different colors?

- Yes, 101 aluminum sheets can be anodized in different colors.

Send your message to us

Mill finished aluminium sheet wih high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords