Mill Finish 1mm Thick Aluminum Coil 5052 H14 for Marine Boats - Aluminum Coil Rolling Thailand

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish 1mm Thick Aluminum Coil 5052 H14 for Marine Boats

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Mill Finish 1mm Thick Aluminum Coil 5052 H14 for Marine Boats

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish 1mm Thick Aluminum Coil 5052 H14 for Marine Boats

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

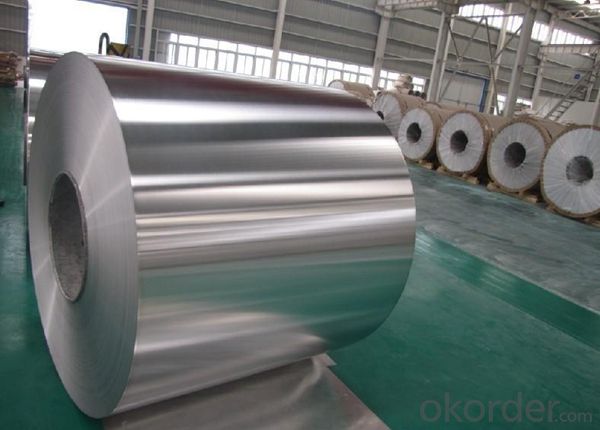

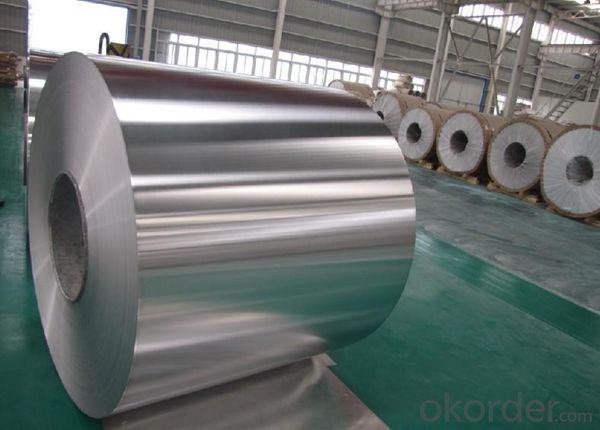

5. Image of Mill Finish 1mm Thick Aluminum Coil 5052 H14 for Marine Boats

6. Package and shipping of Mill Finish 1mm Thick Aluminum Coil 5052 H14 for Marine Boats

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the maximum temperature resistance of aluminum coils?

- The maximum temperature resistance of aluminum coils can vary depending on their specific alloy composition and application. However, in general, aluminum coils can withstand temperatures up to around 600 degrees Fahrenheit (315 degrees Celsius) before their structural integrity and performance may be compromised.

- Q: Can aluminum coils be used in automotive body panels?

- Yes, aluminum coils can be used in automotive body panels. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for automotive applications. The use of aluminum coils in body panels offers several advantages, including improved fuel efficiency due to the reduced weight of the vehicle, better handling and maneuverability, and enhanced durability. Additionally, aluminum is highly recyclable, making it an environmentally friendly option for automotive manufacturing. Many automakers have already started incorporating aluminum coils in their vehicles, and this trend is expected to continue as the industry strives for lighter and more sustainable vehicles.

- Q: Can aluminum coils be used in the production of household appliances?

- Yes, aluminum coils can be used in the production of household appliances. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various applications in appliances such as refrigerators, air conditioners, and cooktops. Additionally, aluminum coils offer excellent heat transfer properties, making them an ideal choice for enhancing energy efficiency in appliances.

- Q: How do aluminum coils contribute to energy-efficient lighting installations?

- Aluminum coils contribute to energy-efficient lighting installations by providing excellent thermal conductivity, which helps dissipate heat efficiently. This reduces the energy consumed by the lighting system and extends the lifespan of the bulbs. Additionally, aluminum coils are lightweight, durable, and corrosion-resistant, making them suitable for various lighting applications.

- Q: What are the different packaging weights available for aluminum coils?

- The different packaging weights available for aluminum coils vary depending on the specific requirements and applications. Common packaging weights for aluminum coils range from 1,000 to 10,000 pounds or more. These weights can be customized to meet the needs of different industries and transportation methods.

- Q: What are the different thickness options for aluminum coils?

- Aluminum coils are available in a wide range of thickness options to cater to various industrial and commercial applications. The thickness of aluminum coils is typically measured in gauge or millimeters (mm). Common thickness options for aluminum coils include: 1. Thin Gauge: Thin gauge aluminum coils are usually between 0.15 mm to 0.4 mm thick. These coils are commonly used for applications that require lightweight and flexible materials, such as packaging, electrical wiring, and insulation. 2. Standard Gauge: Standard gauge aluminum coils range from 0.4 mm to 2.5 mm in thickness. These coils are widely used in industries like construction, automotive, and aerospace for applications such as roofing, cladding, heat exchangers, and structural components. 3. Thick Gauge: Thick gauge aluminum coils are typically above 2.5 mm in thickness. These coils are predominantly used in heavy-duty applications that require high strength, durability, and load-bearing capacity. Examples include shipbuilding, industrial machinery, and large-scale structural frameworks. It's important to note that the availability of specific thickness options may vary depending on the manufacturer and the intended application. Custom thicknesses can also be manufactured to meet specific project requirements.

- Q: What is the typical thermal expansion coefficient for aluminum coils?

- The typical thermal expansion coefficient for aluminum coils is around 23.1 x 10^-6 per degree Celsius (or 23.1 x 10^-6/°C). This coefficient represents the change in length of an aluminum coil per degree Celsius increase in temperature. It is important to note that this value may vary slightly depending on the specific alloy and composition of the aluminum coil.

- Q: Are there any limitations to the maximum coil length of aluminum coils?

- Yes, there are limitations to the maximum coil length of aluminum coils. The length of aluminum coils is typically restricted by factors such as the capabilities of manufacturing equipment, transportation constraints, and handling limitations. Additionally, longer coils are more prone to issues like coil sagging and deformation during storage or handling. Therefore, there is a practical limit to the maximum coil length that can be produced and effectively utilized in various industries.

- Q: Can aluminum coils be used for sound insulation?

- Indeed, sound insulation can be achieved by employing aluminum coils. By virtue of its high density and capacity to absorb and disperse sound waves, aluminum possesses exceptional qualities for soundproofing purposes. When utilized in the form of coils, aluminum effectively obstructs and reflects sound, thereby diminishing noise transmission and furnishing insulation. Moreover, aluminum coils boast effortless installation and exhibit resistance against corrosion, rendering them a robust and enduring choice for soundproofing applications.

- Q: Are aluminum coils suitable for automotive body panels?

- Yes, aluminum coils are suitable for automotive body panels. Aluminum is lightweight, which helps improve fuel efficiency and overall vehicle performance. Additionally, aluminum is highly corrosion-resistant, making it an ideal choice for automotive applications where the panels are exposed to various weather conditions. Its high strength-to-weight ratio also provides excellent durability and crash resistance. Moreover, aluminum can be easily formed and shaped, allowing for intricate and stylish designs. Overall, the use of aluminum coils for automotive body panels offers numerous advantages and is a popular choice among car manufacturers.

Send your message to us

Mill Finish 1mm Thick Aluminum Coil 5052 H14 for Marine Boats - Aluminum Coil Rolling Thailand

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords