MIG200 250 250F Inverter Gas-Shielded Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

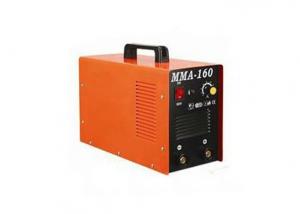

MIG200/250/250F Inverter Gas-Shielded Welding Machine

· Condition: New

· Place of Origin: China (Mainland)

· Brand Name: OEM

· Model Number: MIG200/270/250F

· Dimensions:500*263*430/510*273*440/505*203*375MM

· Weight: 25/26.5/18KGS

· Usage: Auto Repair, Machining, Steel Doors & Windows, Steel Furniture, etc

· Certification: CE; ISO9001:2008; CCC

· Color: orange

Feature

· 1. IGBT inverter technology, up to 30KHZ, uniquely controlled, high reliability, light weight;

· 2. Closed loop feedback, output constant voltage, electric reactance controlled, welding steady;

· 3. MMA/TIG function can be added;

· 4. Switching frequency is out of audio frequency, which almost eliminate noise;

· 5. MIG250FL wire feeder is separated, operation range is wider.

Technical Parameters

· Model | MIG200 | MIG250 | MIG250F |

Rated Input Voltage(V) | 1-220V±10% | 3-380V±10% | 3-380V±10% |

Rated Input Capacity(KVA)MMA/TIG | 7.5 | 9.5 | 9.2 |

Rated Output Current(A) | 200 | 250 | 250 |

Rated Output Voltage(V) | 24 | 27.5 | 27 |

No-load Voltage(V) | 50 | 52 | 48 |

Duty Cycle(%) | 60 | 60 | 60 |

Welding Wire Diameter(MM) | 0.8/1.0 | 0.8/1.0 | 0.8/1.0 |

Wire Feeder Style | Integrated | Integrated | Separated |

- Q: Want to buy a WSE5-315 AC and DC tungsten level manual argon arc welding machine. There are many models on the web, and I don't know if WSE5-315 and WSE315 and WSME315 are the same thing In addition, consult WSE5-315 AC and DC tungsten tungsten argon arc welding machine, the current price and the products of those enterprises are not bad Thank you

- If sufficient funds, the first choice of Tangshan Panasonic YC-300TSP, the price is about 20 thousand. Next, Beijing times PE21-400 price is in 7000 or so, again, Shanghai, Shanghai, industry, WS-315, the price is in more than 5000. The above are DC argon arc welding machine, if not often welded aluminum alloy, then do not buy AC and DC dual-use, very expensive.

- Q: What do you mean by "ground arc" of argon arc welding machine? Is it because it doesn't arc or is it connected directly to the ground to prevent electric shock?

- Some of the ground wires come from the positive electrode, some from the negative electrode, and the electrodes are marked or referenced. The electrodes are directly connected to the welded metal objects before welding.

- Q: What's the reason for this? Tell me about the trouble. I work in argon arc welding, the novice today, dry with a dry suddenly broken, the arc, I thought is a switch or circuit which is broken, later discovered, with tungsten tip with the welding surface contact, causes a spark. What are the reasons for seeking advice?.

- First of all, to see if you hit the welding gear, try another gear,If not, check that the high frequency part is faulty,Arcing indicates that the main circuit is not broken

- Q: How to use the arc welding machine?

- Aluminum can focus on argon arc welding argon arc welding of Odin Wei, Wei Odin have special customer service and debugging

- Q: Argon arc welding machine general how much money? Which brand is better?.

- Wuxi Han God, Wuxi Fenghua, buy about 800 on it.

- Q: I wonder what the formula for calculating the power of electric welding is. There are several gears in the two output, and my calculations seem to be out of order. I think my calculation is wrong. I would like to ask you a complete calculation method of welding power

- It depends on what type of welding machine, how much current welding, and the length of the welding cable to estimate:1. Commonly known as: AC arc welding arc welding transformer, mainly BX1-500, BX3-500 to 300A; if the current welding, the power consumption per hour is about 8.4 degrees (according to the welding efficiency of 80%, the utilization rate of 70%, the welding voltage 32V calculation);2. SCR rectifier welding: ZX5-500; if the current is welded by 300A, its power consumption per hour is about 8.96 degrees (press welding efficiency 75%, utilization rate 70%, welding voltage 32V calculation);3. Inverter welding machine: ZX7-500: if the current is welded by 300A, the power consumption is about 7.47 degrees per hour (90% of the welder efficiency, 70% of the use rate, and 32V of the welding voltage);The above calculations assume that the length of the welded cable is 0 meters, and the actual power consumption will be greater because of the loss of the welding cable.

- Q: Can argon arc welding machine be welded without argon gas?

- No, you first need to understand the role of argon, argon is inert gas, almost without any material reaction (limit exceptions), so use it to open air, high temperature protection welding metal and welding torch tungsten pole argon arc welding is often used for sheet metal or lively, for example: very thin carbon steel, stainless steel and so on, if the AC argon arc welding, aluminum welding can Aluminum Alloy.Without argon protection, 1, the welding of high temperature metal will react with the air, blackening, porosity, welding quality is very poor. 2. The tungsten electrode of the welding gun reacts with the air and burns rapidly.Think about it, your tungsten filament bulb, if you remove the glass cover, quite in contact with the air, tungsten filament instant evaporation!

- Q: What kind of argon arc welding machine is used is manual welding and argon arc welding switch? What's the connection between direct current and pulse? The more detailed the better, for example, when to switch to manual welding, when the use of argon arc welding, when the use of DC or pulse, how they match, and so on. ThanksAlso, what are the main aspects of direct current argon arc welding? What's welding? What are the main uses of pulse argon arc welding? What's welding? Is manual welding direct current or pulse? What's the main weld? Manual welding is not the kind of electrode welding?

- This is your welding machine DC welding machine, it has two kinds of manual welding and argon arc welding, manual welding is the welding, soldering or welding can, stainless steel, argon arc welding can also iron welding of stainless steel. A pulse is in the welding process, as is your pulse, jump when welding, when the jump is not welding, when you press the switch, it will fire pounding, in fact it is working in high current low current, high current work. Then, low current work, continuous circulation, circulation speed can be fast or slow, you should adjust current regulation of the highest and the lowest current switch, you let it stop. The general pulse is used to burn automatic welding, the welding effect scales with more. Here you don't actually mean DC pulse, you switch it by welding, it will not upset the meaning of welding switch.

- Q: Mainly used for welding stainless steel anti-theft network, doors and windows can be portable, please say specific parameters, brands, and the approximate price! Thank you. The answer is satisfactory!

- Based on what you said, I recommend the use of portable inverter argon arc welding machine can be a 200A, select the most suitable current, many brands now, there is less expensive, cheap usually use MOS tube to do, your point is to do with IBGT, the weight is about 10KG, I don't know where you are, but I suggest you find a good brand in your local buy or, in this case the maintenance is more convenient, if the price should be around 1200---1500, generally not more than 1500

- Q: Can argon arc welding machine be used as cutting machine?

- It should be possible to change the gas to compressed air and adjust the current to the extent that it can be burned through the material. These have to be tested for long experience. In addition, argon saves some of the possible tungsten charges, and uses argon and tungsten to save some. You can change the electrode during the test to see if the effect is better.

Send your message to us

MIG200 250 250F Inverter Gas-Shielded Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords