Mica Roll Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

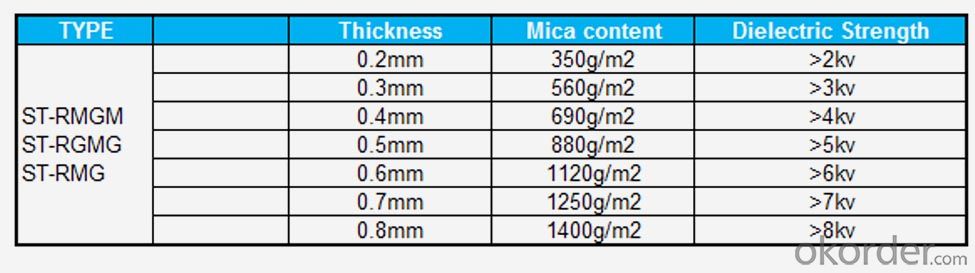

Phologpite mica roll is a result of specially pressed mica product which is made of phologpite mica paper and silicon resin. The thickness ranges

from 0.2mm to 0.8mm, breakdown voltage is above 15KV, tensile strength is above N/15mm and temperature resistance is above 800°C.

◆ ST-RMGM: phlogopite mica paper with glass fiber cloth inside. AVAILABILITY CHARACTERISTIC |

|

- Q: Who can tell me what is neutral refractory?

- It is a material that can resist acidic and basic slag, flux and chemical erosion form other refractories at high temperatures. The main components include carbon, silicon carbide, aluminum oxide, chromium oxide and other trivalent oxides, such as carbon refractories and chrome refractories, etc. Strictly speaking, neutral refractories refer only to the carbonaceous refractories, including carbon brick and graphite silicon carbide products, etc. Sometimes, high alumina refractories with high Al2O3 content also belong to this material, such as some materials that are acidic but tend to be basic refractories, like sillimanite, mullite bricks and corundum bricks. Recently developed aluminum carbon bricks, zirconium carbon bricks alumina - silicon carbide - carbon bricks, silicon nitride bonded silicon carbide brick and so on are also neutral refractories. This material can be used in the bottom of blast furnace, the lining of hearth and bosh, and the lining of aluminum electrolytic cell, calcium carbide furnace, ferroalloy furnace, molten steel ladle, plating tank, reaction tank, and autoclave and so on.

- Q: what is the requirements of roofing insulation materials fire rating?

- The fireproofing requirements of architectural design are regulated by architectural design fire?safety?rules, roofing insulation material only has the requirements of materials combustion performance, namely non-combustible material. No fire rating requirements.

- Q: What is molten silicon? What refractoriness do refractories made by it have? What properties of using does it have?

- Molten silicon can be called quartz glass, which shows an amorphous silicon state. It is a liquid fusion at above 1723 degree and is an ultra-cooling state at low temperatures. It is not generated in refractories, but generated in the matrix, showing liquid state at a high temperature capable of buffering the stress with somewhat binding properties. If quartz glass is used as refractory, its function are melrly these ones. (These are what I konw for reference only.)

- Q: Which refractory quality inspection authority is good?

- National testing agencies include National Refractory Inspection Center (i.e. LIRR), China Building Materials Academy (Guanzhuang, Beijing), National Center for Ceramic and Refractory Materials Inspection (Shandong) and China Metallurgical Research Institute (Beijing).

- Q: The difference between refractory and thermal insulation material

- Refractory refers to inorganic non-metallic material, whose refractoriness is not less than 1,580℃, but refractory is not necessarily insulated material. Inorganic thermal insulated material also belongs to refractory as long as its refractoriness is higher than 1,580℃.

- Q: What are fireproofing materials?

- Class A incombustible material: Granites, marbles, terrazzos, cement products, concrete products, plasterboards, clay products, glass, tiles, mosaics, steel, aluminum, copper alloys; B1 class flame nonflammable materials: Ceiling materials: gypsum plaster boards, fibrous plasters, cement particle boards, mineral wool decorative acoustic panels, glass wool decorative acoustic boards, perlite decorative acoustic boards, flame retardant plywoods and medium density fiberboards, rock wool decorative panels, flame retardant woods, aluminum foil composite materials, flame retardant phenolic laminates, aluminum foil glass fiber reinforced plastic composite materials; Wall covering: gypsum plaster boards, fibrous plasters, cement particle boards, mineral wool boards, glass wool boards, perlite boards, flame retardant plywoods, flame retardant medium density fiberboards, fireproof plastic decorative plates, nonflammable double-sided particle boards, multicolor paints, nonflammable wallpaper and textile wall cloth, flame retardant simulated granite decorative plates, magnesium oxychloride cement prefabricated wall panels, flame retardant glass fiber reinforced plastic plates, PVC plastic clapboards, high-strength and lightweight composite wallboards, fire-retardant molded wood composite boards, flame retardant colored artificial boards, nonflammable glass fiber reinforced plastics, etc.

- Q: What's the refractoriness and how to measure the refractoriness?

- Bottom each side length is 8 mm and upper side length is 2 mm. Under a certain temperature-rising speed, when heating, refractory's resistance to high temperature from melting is called refractoriness. The properties of cross section into an equilateral triangle and height is 30 mm. When it bends down until the vertex and chassis contact temperature is the refractoriness of sample. It bends due to the influence of its weight. Make the will-measured material into standard pyrometric cone.

- Q: Which are roofing fireproofing material?

- (1) Foamed concrete is a kind of fire-proof thermal inuslation matertial featured by good fire resistance and thermal insulation. Besides, it is also characterized by excellent sound proofing, penetration resistance, easy construction, safety and environmental protection without toxin and pollution. (2) Foam glass is featured by light weight, small heat conductivity coefficient and water absorbption, non-inflammability, fire resistance, high strength, no moulding, corrosion resistance, non-toxin and stable physical and chemical properties and thus widely used petroleum, chemical engineering and underground construction. It is also featured by thermal insualtion, heat/cold preservation and sound absorbption and thus can be used for thermal insulation of external wall and roof of civil builduing. Foam glass is featured by stable chemical property, easy to be processed and not easy to deforme, and durable. (3) With slag, basalt and other natural ore as the main raw material, rock wool, mineral wool and its products are made by high temperature melting into fiber, and then processing with binder. It has low thermal conductivity, fire resistance, easy construction and good effects of energy saving and thus is highly cost-effective. (4) With phenolic foam material as main material, phenolic resin plate is made by foaming thermoset phenolic resin. It is featured by light weight, fire resistance, no burning in the air, no smoking, non-toxin, no dropping and non-embrittlement and thus is an ideal thermal insulation material used in HAVC projects. Due to its high obturator formamen rate, low heat conductivity coefficient, good thermal insulation, water resistance and water vapor permeability, phenolic foam is an ideal thermal insulation material.

- Q: What are the additives and recipes of refractory?

- Water reducing agent is to evidently reduce mixing water content while keep the slamp value of refractory castable almost invariant, also known as fluid loss agent. Water reducing agent itself cannot have chemical reaction with material component or compose new chemical compound, but it just seemingly has physical and chemical reactions. The binding agent of refractory castable is calcium aluminate cement combined with clay and oxide micro powder. In commonly used water reducing agents, the inorganic includes sodium pyrophosphate (Na4P2O7), sodium tripolyphosphate (Na5P3O10), sodium hexametaphosphate [(NaPO3) 6], super sodium polyphosphate (Na2P4O11), sodium silicate (Na2O · nSiO2 · mH2O), and so on; the organic includes lignosulphonate water reducer (sodium lignosulphonate, calcium lignosulphonate); naphthalene water reducer (naphthalene sulfonate or naphthalene homologues with formaldehyde condensate): water soluble resin water reducing agent (sulfonated melamine formaldehyde resin, abbreviated as composite of melamine water reducer).

- Q: I wanna ask about the thermal insulation material fire resistant level?

- The inorganic have glass wool \ foam glass Bian \ the best of organic is phenolic foam \ phenolic foam composite cement layer is level A.

Send your message to us

Mica Roll Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords