Melt Extract Stainless Steel Fiber - Straight Type CE Approved High Quality Hooked

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

Steel fiber types includs,

a) Hooked ends steel fiber

b) Flat head steel fiber

c) Needle-flat steel fiber

d) Wavy steel fiber

e) Xorex steel fiber

f) Micro-steel fiber

g) stainless steel fiber

Application of Daye steel fiber:

A. Tunnel pre-treatment(primary support)

B. Tunnel forming(permanent lining)

C. Slope stabilization

D. Ditch excavation support

E. Industrial floor

F. Precast concrete element

G. Concrete restoration

H. High performance concrete

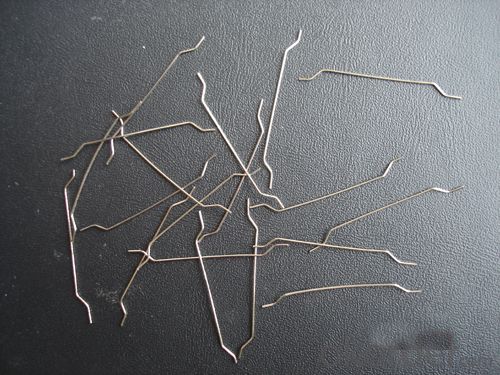

Picture

Steel fiber straight type

Wavy steel fiber

Xorex steel fiber

Micro-steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Can melt extract stainless steel fiber be used in precast concrete products?

- Yes, melt extract stainless steel fiber can be used in precast concrete products. It enhances the strength, durability, and crack resistance of the concrete, making it a suitable choice for precast applications.

- Q: What is melt extract stainless steel fiber?

- Melt extract stainless steel fiber refers to a high-performance reinforcing fiber that is made from stainless steel through a process called melt extraction. During this process, the stainless steel is melted and then rapidly solidified to form fine, continuous fibers. These fibers are typically used as a reinforcement material in various applications, such as concrete and refractory materials. They are known for their exceptional strength, durability, and resistance to corrosion, making them an ideal choice for demanding environments. The use of melt extract stainless steel fibers in concrete improves its mechanical properties, including flexural strength, impact resistance, and crack resistance. This reinforcement enhances the overall performance and longevity of concrete structures, particularly in applications where high strength and durability are required, such as industrial flooring, tunnel linings, and bridge decks. In refractory materials, melt extract stainless steel fibers are used to enhance the thermal shock resistance and mechanical strength of the material. These fibers can withstand extreme temperatures, making them suitable for applications in furnaces, kilns, and other high-temperature environments. Overall, melt extract stainless steel fibers offer a versatile and reliable solution for reinforcing various materials, providing increased strength, durability, and resistance to corrosion and thermal shock.

- Q: How does the dosage of melt extract stainless steel fiber affect its performance in concrete?

- The dosage of melt extract stainless steel fiber directly impacts its performance in concrete. Increasing the dosage of stainless steel fiber enhances the concrete's resistance to cracking, improves its flexural and tensile strength, and enhances its durability. Higher dosages of stainless steel fiber also enhance the concrete's resistance to impact and abrasion. However, excessive dosage may lead to an increase in the viscosity of the concrete mix, which can affect its workability. Therefore, finding the optimal dosage is crucial to achieve the desired performance in concrete.

- Q: Can melt extract stainless steel fiber be used in the construction of wastewater treatment plants?

- Yes, melt extract stainless steel fiber can be used in the construction of wastewater treatment plants. It is a durable and corrosion-resistant material that can withstand the harsh and corrosive conditions found in wastewater treatment facilities. Additionally, the high temperature resistance of stainless steel fiber makes it suitable for use in various components of the plant, such as tanks, pipes, and filters.

- Q: What is the effect of melt extract stainless steel fiber on the drying shrinkage of shotcrete?

- The use of melt extract stainless steel fiber in shotcrete can have a significant effect on the drying shrinkage of the material. Stainless steel fibers are known for their high tensile strength and resistance to corrosion, making them an ideal reinforcement material for shotcrete. When added to shotcrete mixtures, the stainless steel fibers help to distribute the shrinkage stresses throughout the material, reducing the overall drying shrinkage. This is due to the fibers acting as a reinforcement, providing additional strength and stability to the shotcrete. The presence of stainless steel fibers in shotcrete also helps to improve the overall durability and crack resistance of the material. This is particularly important in applications where shotcrete is exposed to harsh environmental conditions or subjected to heavy loads. Additionally, the use of stainless steel fibers can reduce the formation of plastic shrinkage cracks during the curing process. These cracks can occur due to the rapid evaporation of moisture from the shotcrete surface, leading to shrinkage and subsequent cracking. By reinforcing the shotcrete with stainless steel fibers, the material becomes more resistant to cracking and maintains its structural integrity. Overall, the addition of melt extract stainless steel fiber to shotcrete can greatly reduce the drying shrinkage of the material, improve its durability, and enhance its crack resistance. This makes it a valuable reinforcement option for shotcrete applications in various construction projects.

- Q: How does the addition of melt extract stainless steel fiber affect the ductility of concrete?

- The addition of melt extract stainless steel fiber generally enhances the ductility of concrete. Stainless steel fibers are known for their high tensile strength and excellent corrosion resistance. When added to concrete, they help to bridge cracks and improve the overall flexural performance of the material. Concrete is a brittle material that tends to crack under tensile stress. These cracks can propagate and ultimately lead to failure. However, by incorporating stainless steel fibers, the concrete's ability to withstand tensile forces is greatly improved. The fibers act as reinforcement, increasing the material's resistance to cracking and improving its overall ductility. The presence of stainless steel fibers in concrete also helps to distribute stress more evenly throughout the matrix. This prevents the concentration of stress at specific points, making the material less prone to brittle failure. As a result, the concrete becomes more flexible, allowing it to absorb more energy before reaching its breaking point. Additionally, stainless steel fibers can help to reduce shrinkage and minimize the formation of plastic shrinkage cracks in concrete. This is particularly beneficial in situations where the concrete is subjected to drying conditions or temperature fluctuations. Overall, the addition of melt extract stainless steel fiber to concrete positively affects its ductility by improving its crack resistance, enhancing its flexural performance, and increasing its energy absorption capacity.

- Q: How does melt extract stainless steel fiber improve the impact resistance of shotcrete?

- Melt extract stainless steel fiber serves as a reinforcement material that is incorporated into shotcrete, a versatile construction material with various uses. The inclusion of this stainless steel fiber in shotcrete greatly enhances its ability to withstand impact. The primary reason for this enhancement stems from the unique properties of stainless steel fiber. Firstly, stainless steel possesses a high tensile strength, allowing it to endure significant force without breaking or distorting. This characteristic enables the stainless steel fiber to effectively distribute and absorb the energy from impacts, minimizing the occurrence of cracks or fractures in the shotcrete. Moreover, the melt extract process employed to manufacture these fibers ensures a consistent and uniform shape, size, and distribution. This uniformity contributes to the overall stability and durability of the shotcrete, rendering it more resistant to impact loads. Additionally, the addition of stainless steel fibers to shotcrete enhances its ductility, which refers to its ability to deform without fracturing. By increasing the ductility of shotcrete, the stainless steel fibers enable it to absorb energy more effectively during impact events, preventing sudden failures or catastrophic damage. In summary, the utilization of melt extract stainless steel fibers in shotcrete significantly bolsters its impact resistance by augmenting its tensile strength, stability, durability, and ductility. Consequently, shotcrete reinforced with stainless steel fibers becomes an optimal choice for applications where impact loads are anticipated, such as in tunnel linings, bridge abutments, or protective barriers.

- Q: How does melt extract stainless steel fiber improve the resistance to fatigue in concrete?

- Concrete's resistance to fatigue can be significantly improved by incorporating melt extract stainless steel fiber. These fibers play a crucial role in enhancing the durability and performance of concrete structures, particularly in high-stress environments. One of the primary benefits of melt extract stainless steel fiber is its ability to enhance the flexural strength of concrete, thereby improving its resistance to fatigue. These fibers are evenly distributed throughout the concrete matrix, creating a three-dimensional reinforcement system. This reinforcement mechanism helps to evenly distribute stress and load, which reduces stress concentration in specific areas and prevents crack propagation. Additionally, the high tensile strength of stainless steel fibers provides further support to the concrete, augmenting its resistance to fatigue. Acting as mini-reinforcements, these fibers bridge any cracks that may form during repeated loading and unloading cycles. This bridging effect effectively inhibits crack growth and propagation, thereby maintaining the structural integrity of the concrete over time. Moreover, the corrosion resistance of stainless steel fibers is another crucial factor in improving fatigue resistance. Concrete structures are often exposed to harsh environments, such as those rich in chloride or alkaline substances, which can cause traditional steel reinforcements to corrode. However, stainless steel fibers exhibit exceptional resistance to corrosion, ensuring the long-term durability and performance of the concrete. In conclusion, the incorporation of melt extract stainless steel fiber enhances concrete's resistance to fatigue by improving its flexural strength, providing additional support, and offering corrosion resistance. These advantageous properties result in a more durable and resilient concrete structure capable of withstanding repeated stress and loading cycles, ultimately extending its lifespan and reducing maintenance costs.

- Q: Is melt extract stainless steel fiber compatible with all types of concrete additives?

- Most types of concrete additives are generally compatible with melt extract stainless steel fiber. Nevertheless, it is crucial to verify the precise compatibility of the fiber with the additives incorporated in your concrete mixture. Specific accelerators or superplasticizers, for instance, could potentially trigger negative reactions when combined with stainless steel fibers. To ensure compatibility, it is advisable to consult the manufacturer or supplier of both the stainless steel fiber and concrete additives prior to their usage in your concrete mixture.

- Q: Can melt extract stainless steel fiber be used in precast concrete beams or columns?

- Yes, melt extract stainless steel fiber can be used in precast concrete beams or columns. This type of fiber is commonly used as a reinforcement material in concrete structures due to its high strength and durability. The addition of stainless steel fiber can enhance the flexural and tensile strength of precast concrete beams and columns, making them more resistant to cracking and improving their overall performance. Additionally, stainless steel fibers have excellent corrosion resistance properties, which makes them suitable for use in environments where concrete structures are exposed to moisture or chemicals. Overall, using melt extract stainless steel fiber in precast concrete beams or columns can help increase their longevity and structural integrity.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type CE Approved High Quality Hooked

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords