Melt Extract Stainless Steel Fiber Reinforced Concrete Admixtures from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland)

Model Number: steel fiber

material: steel wire

application: concrete reinocement

type: end hook steel fiber

Product features

with excellent tensile ,hightenacity ,against cracking and fatigue ,they`re widely usd in the structures made of concrete

Service Temperature:

Melting Point | Recommended Maximum Service Temperature | ||||

310 | 1380-1455℃ | Cyclic Heating | 1000℃ | Continuous Service | 850℃ |

Dimensions:

Lengths are 6/10/15/25/30/50/60mm. Other lengths can be manufactured specifically to suit customer’s requirements.

Equivalent diameter 0.2/0.4/0.5/0.6/0.75/1.0mm. Other diameters can be manufactured specifically to suit customer’s requirements.

Packing:

Fibres are packed in 1/5/10/20kg cartons then put on pallets. Other packaging can be supplied if requested.

Using method and using quantity:

Usually use 0.2-2% ( volume ) of steel fiber in refractories or concrete materials, mixed evenly to maximize the use effect of steel fiber into full play. Mix method :1. Wet mix; 2. Dry mix.

In order to prevent explosions & radiation for concrete buildings , it is recommended to use steel fibres number 40-60% (volume).

Specifications

1.hooked steel fiber

2.CE and ISO9001:2008

3.diameter from 0.5mm to 1.2mm

4.competitive price,high quality and service

Hooked Steel Fiber:

1.Diameter:0.5mm-1.0mm

2.Length: 25mm-60mm

3.Material: low carbon steel wire

4.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

5.Uses: high way,tunnel,building,airport road serface and so on .

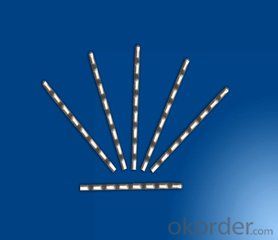

Picture

steel fiber concrete reinforced

any type steel fiber

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

with excellent tensile ,hightenacity ,against cracking and fatigue ,they`re widely usd in the structures made of concrete

- Q: Can melt extract stainless steel fiber be used in high-performance or self-compacting concrete?

- Melt extract stainless steel fiber is capable of being utilized in high-performance or self-compacting concrete. Renowned for their exceptional tensile strength, corrosion resistance, and durability, stainless steel fibers are ideal for concrete applications that necessitate high-performance or self-compacting properties. By incorporating these fibers, the mechanical properties of the concrete, such as flexural strength, impact resistance, and crack resistance, can be enhanced. Moreover, stainless steel fibers offer augmented resistance to shrinkage and thermal cracking, rendering them suitable for deployment in extreme weather conditions or environments characterized by significant temperature fluctuations. In summary, melt extract stainless steel fibers possess the ability to contribute to the heightened performance and prolonged lifespan of high-performance or self-compacting concrete applications.

- Q: What is the typical fiber length of melt extract stainless steel fiber?

- The typical fiber length of melt extract stainless steel fiber can vary depending on the specific product and manufacturer. However, on average, melt extract stainless steel fibers typically have a fiber length ranging from 3 mm to 25 mm. This length is suitable for various applications, such as reinforcement of concrete and other composite materials, thermal insulation, and electromagnetic shielding. It is important to note that different industries and uses may have specific requirements for fiber length, so it is always recommended to consult the manufacturer or supplier for the exact specifications needed for a particular project.

- Q: Can melt extract stainless steel fiber enhance the resistance of concrete to acid attack?

- The resistance of concrete to acid attack can be enhanced by melt extract stainless steel fiber. Renowned for their high corrosion resistance and durability, stainless steel fibers form a network within the concrete that enhances its strength and performance. Concrete is prone to deterioration and damage when exposed to acid attack. Acids react with the calcium hydroxide in the cement paste, causing the dissolution of the concrete matrix and a decrease in its strength. However, the incorporation of stainless steel fibers into the concrete mix creates a barrier that prevents direct contact between the acid and the cement paste. The stainless steel fibers act as reinforcement, improving the mechanical properties of the concrete. They provide extra strength and toughness, increasing its resistance to acid attack. Furthermore, the fibers contribute to stress distribution and reduce crack formation, further safeguarding the concrete against acid penetration. Moreover, the corrosion resistance of stainless steel fibers ensures their integrity even in harsh environments. As a result, they can continue to reinforce and protect the concrete for an extended period. In summary, melt extract stainless steel fiber significantly enhances the resistance of concrete to acid attack. It reinforces the material, prevents direct contact between acids and the cement paste, and improves the durability of the concrete.

- Q: Can melt extract stainless steel fiber be used in racetrack pavements?

- Yes, melt extract stainless steel fiber can be used in racetrack pavements. Its high tensile strength and resistance to corrosion make it suitable for reinforcing asphalt or concrete pavements in racetracks, improving their durability and reducing the potential for cracking or fatigue failure. Additionally, the addition of stainless steel fibers can enhance the pavement's resistance to heavy loads, temperature variations, and environmental factors commonly encountered in racetrack environments.

- Q: Can melt extract stainless steel fiber be used in precast bridge column elements?

- Yes, melt extract stainless steel fiber can be used in precast bridge column elements. It is commonly used to enhance the mechanical properties and durability of concrete, making it suitable for high-performance applications such as bridge construction. The addition of stainless steel fibers improves the flexural strength, crack resistance, and overall structural integrity of the precast elements, making them more robust and able to withstand the demands of bridge column construction.

- Q: Does melt extract stainless steel fiber improve the resistance to chloride penetration of concrete?

- Yes, melt extract stainless steel fiber can improve the resistance to chloride penetration of concrete. Chloride penetration is a major cause of corrosion in concrete structures, particularly in coastal or industrial areas where chloride ions are present in high concentrations. The addition of stainless steel fibers to the concrete mix can create a network of reinforcement that enhances the durability and resistance of concrete to chloride attack. The stainless steel fibers act as a physical barrier, reducing the permeability and ingress of chloride ions into the concrete matrix. This helps to prevent or delay the onset of corrosion and extends the service life of the concrete structure. Additionally, the stainless steel fibers can provide additional strength and toughness to the concrete, enhancing its overall performance and durability. Therefore, the use of melt extract stainless steel fiber in concrete can be an effective strategy to improve the resistance to chloride penetration and increase the durability of concrete structures.

- Q: What is the effect of melt extract stainless steel fiber on the post-cracking behavior of concrete?

- The effect of melt extract stainless steel fiber on the post-cracking behavior of concrete is significant. When stainless steel fibers are added to concrete, they act as reinforcement and enhance the tensile strength and ductility of the material. This reinforcement helps to control cracking in the concrete and improve its performance under various loading conditions. The addition of melt extract stainless steel fibers in concrete increases its ability to resist cracking and reduces the chances of brittle failure. These fibers are typically thin and long, which allows them to distribute stress more evenly throughout the concrete matrix. As a result, the concrete can withstand higher tensile and flexural stresses without developing significant cracks. Moreover, the use of stainless steel fibers improves the post-cracking behavior of concrete by reducing crack widths and increasing crack resistance. This is particularly beneficial in structures subjected to dynamic or cyclic loading, such as bridges or pavements. The steel fibers help to limit crack propagation and prevent the formation of wide cracks, which can compromise the structural integrity and durability of the concrete. Additionally, melt extract stainless steel fibers can also enhance the durability of concrete by reducing the risk of corrosion. Stainless steel is highly resistant to corrosion, even in aggressive environments, making it an ideal reinforcement material for concrete exposed to moisture, chloride ions, or other corrosive substances. This resistance to corrosion ensures the long-term performance and service life of the concrete. In summary, the addition of melt extract stainless steel fiber to concrete has a positive effect on its post-cracking behavior. It improves the tensile strength, ductility, crack resistance, and durability of the material. These benefits make stainless steel fibers an excellent choice for reinforcing concrete structures, enhancing their overall performance and longevity.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of brittleness of concrete?

- The effect of melt extract stainless steel fiber on the modulus of brittleness of concrete is to significantly reduce it. Stainless steel fibers are typically added to concrete mixes to enhance its toughness and ductility. By dispersing the fibers throughout the concrete matrix, they act as reinforcement and help to distribute stress more evenly. This results in concrete with improved resistance to cracking and increased flexural strength. The addition of stainless steel fibers also helps to control and limit crack propagation in concrete, reducing its brittleness. The fibers act as a barrier to prevent cracks from propagating further, leading to a more durable and resilient material. This improved resistance to cracking and enhanced ductility ultimately increase the modulus of brittleness of concrete. The melt extract stainless steel fibers, in particular, are known for their high tensile strength and excellent corrosion resistance. This makes them an ideal choice for reinforcing concrete in harsh environments where corrosion is a concern, such as coastal areas or structures exposed to chemicals. By incorporating melt extract stainless steel fibers into concrete, the overall performance and longevity of the material are greatly improved. In summary, the addition of melt extract stainless steel fibers to concrete significantly reduces its modulus of brittleness by enhancing toughness, ductility, and crack resistance. This results in a more durable and resilient concrete that can withstand higher levels of stress and strain without failure.

- Q: Is melt extract stainless steel fiber suitable for use in self-compacting concrete?

- Yes, melt extract stainless steel fiber is suitable for use in self-compacting concrete. It provides excellent reinforcement, improves the durability and ductility of the concrete, and enhances its resistance to cracking and impact.

- Q: What is the impact of melt extract stainless steel fiber on the shrinkage of concrete?

- The impact of melt extract stainless steel fiber on the shrinkage of concrete is that it helps to reduce or mitigate the shrinkage cracks that can occur during the curing and drying process of concrete. The steel fibers provide reinforcement and improve the overall strength and durability of the concrete, thereby reducing the potential for shrinkage and cracking.

Send your message to us

Melt Extract Stainless Steel Fiber Reinforced Concrete Admixtures from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords