Melt Extract Stainless Steel Fiber Slit Sheet 330

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

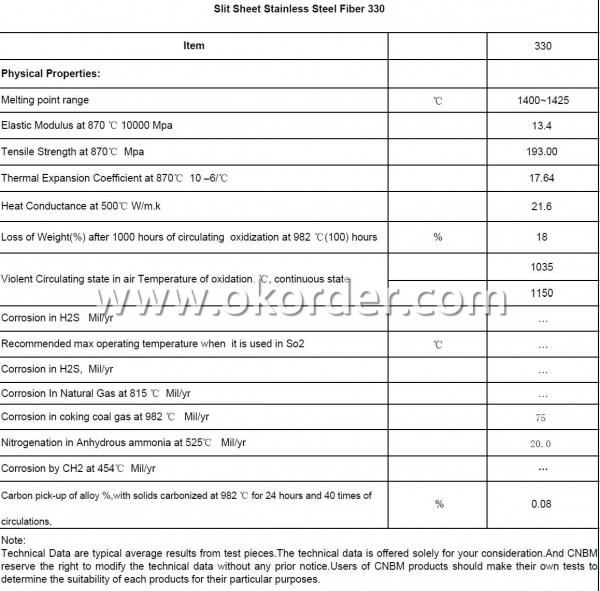

General Information of Slit Sheet Stainless Steel Fiber 330

CMAX cold drawn stainless steel fiber is manufactured by high quality stainless steel wire, mainly used for castable requirements in refractory field, with high tensile strength and low ductility. It can improve refractory performance. Our products can save labor costs.

CMAXmelt extract stainless steel fibercan improve refractories performance and durability, decreasing cost.

CMAX Slit Sheet Stainless Steel Fiber 330 has good performance with the following characteristics:

Light weight

Improve refractories’ performance

Improve refractories’ longevity

Improve refractories’ durability

Significantly reducing downtime and maintance cost

CMAX Slit Sheet Stainless Steel Fiber 330 is available in a wide variety of application:

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our steel fiber is widely used in the world.Our company has success in its melt extract stainless steel fiberproducts due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiberapplication and would like to assist you in product selection, system design, and installation techniques. We can serve the good quality of melt extract stainless steel fiber, We look forward to your cooperation .

- Q: How does melt extract stainless steel fiber affect the freeze-thaw resistance of concrete?

- Concrete's freeze-thaw resistance can be significantly enhanced by the addition of melt extract stainless steel fibers. These fibers are incorporated into the concrete mix during the mixing process, acting as reinforcement within the concrete matrix. During freeze-thaw cycles, the water present in the concrete expands as it freezes, exerting pressure on the surrounding material. This pressure can cause cracking and deterioration of the concrete. However, the inclusion of melt extract stainless steel fibers helps to address this issue. The fibers form a three-dimensional network within the concrete, effectively reinforcing it and improving its ability to resist cracking. They enhance the concrete's tensile strength and ductility, enabling it to better withstand the expansion and contraction resulting from freeze-thaw cycles. In addition, the stainless steel composition of these fibers offers excellent corrosion resistance. This is particularly important in freeze-thaw conditions where the presence of water and deicing salts can accelerate the corrosion process. By preventing corrosion, the fibers ensure the structural integrity and durability of the concrete over time. In conclusion, the integration of melt extract stainless steel fibers into concrete enhances its freeze-thaw resistance by reducing cracking, improving tensile strength, and providing corrosion resistance. This leads to a more resilient and long-lasting concrete structure capable of withstanding harsh environmental conditions.

- Q: Can melt extract stainless steel fiber be used in high-density concrete?

- Melt extract stainless steel fiber is indeed applicable in high-density concrete. It is a common practice to incorporate stainless steel fibers into concrete mixes to enhance the overall strength, durability, and crack resistance of the material. In particular, high-density concrete, which is typically utilized in scenarios where a denser and sturdier substance is required, can reap the benefits of incorporating stainless steel fibers. These fibers work to reinforce the concrete and bolster its capacity to withstand significant loads, impacts, and other forms of stress. Furthermore, stainless steel fibers possess remarkable corrosion resistance properties, rendering them suitable for use in high-density concrete that may be exposed to harsh environmental conditions. All in all, utilizing melt extract stainless steel fibers in high-density concrete yields a more robust and enduring material that is better suited for demanding applications.

- Q: How does melt extract stainless steel fiber improve the resistance of concrete to chloride ingress?

- Melt extract stainless steel fiber plays a crucial role in enhancing the resistance of concrete to chloride ingress. When added to the concrete mixture, these stainless steel fibers provide a physical barrier that impedes the movement of chloride ions into the concrete matrix. Chloride ions are a leading cause of corrosion in reinforced concrete structures, as they penetrate the concrete and reach the steel reinforcement, leading to its corrosion and eventual degradation. This corrosion not only compromises the structural integrity of the concrete but also reduces its service life. The presence of melt extract stainless steel fibers in the concrete effectively reduces the permeability of the material, limiting the ingress of chloride ions. These fibers create a network within the concrete, forming a three-dimensional reinforcement system that restricts the movement of chloride ions. Additionally, the stainless steel fibers enhance the mechanical properties of the concrete, making it more resistant to cracking and spalling caused by chloride-induced corrosion. They improve the tensile and flexural strength of the concrete, minimizing the potential for crack formation and propagation. Furthermore, melt extract stainless steel fibers also act as a sacrificial anode, preventing the corrosion of the steel reinforcement. As the chloride ions come into contact with the stainless steel fibers, they are attracted to the fibers instead of the reinforcement, reducing the risk of corrosion. In summary, melt extract stainless steel fibers improve the resistance of concrete to chloride ingress by creating a physical barrier, reducing permeability, enhancing mechanical properties, and acting as a sacrificial anode. These fibers significantly extend the service life of concrete structures by mitigating the detrimental effects of chloride-induced corrosion.

- Q: Does melt extract stainless steel fiber improve the ductility of concrete?

- Yes, melt extract stainless steel fiber can improve the ductility of concrete. Stainless steel fibers, when added to concrete, can enhance its flexural strength and toughness. These fibers act as reinforcement within the concrete matrix, creating a network that helps to distribute stress and prevent crack propagation. This reinforcement increases the ability of concrete to deform and absorb energy before failure, thus improving its ductility. Additionally, stainless steel fibers have high tensile strength and corrosion resistance, which further contribute to the improved ductility of concrete.

- Q: Can melt extract stainless steel fiber be used in the construction of airport runways?

- Yes, melt extract stainless steel fiber can be used in the construction of airport runways. It is a strong and durable material that can enhance the overall strength and lifespan of the runway. Moreover, stainless steel fibers are corrosion-resistant, which is essential for airport runways exposed to various weather conditions. Additionally, these fibers can help reduce cracking and enhance the resistance to heavy loads, making them suitable for runway construction.

- Q: How does melt extract stainless steel fiber improve the resistance to seismic loading in concrete?

- Melt extract stainless steel fiber is a type of reinforcement material that can significantly enhance the resistance to seismic loading in concrete structures. Seismic loading refers to the stress and vibrations experienced by buildings during earthquakes or other seismic events. One of the key mechanisms through which melt extract stainless steel fiber improves seismic resistance in concrete is by enhancing its tensile strength and ductility. Stainless steel fibers are incredibly strong and are capable of withstanding high levels of stress and strain. When added to concrete, these fibers act as a reinforcement, bridging the cracks that occur under seismic loading and preventing them from propagating further. Moreover, melt extract stainless steel fiber also improves the bond between concrete and other construction materials, such as reinforcing bars or steel frames. This increased bond strength helps to distribute the seismic forces more evenly throughout the structure, reducing localized stress concentrations and improving overall stability. Another significant advantage of using melt extract stainless steel fiber in concrete is its ability to absorb and dissipate energy during seismic events. When the ground shakes, the fibers absorb the energy generated by the seismic forces, preventing it from being transferred to the concrete matrix. This energy absorption capability helps to reduce the overall stress on the concrete and enhances its ability to withstand seismic loading. Additionally, melt extract stainless steel fiber can also improve the durability and longevity of concrete structures in seismic regions. The fibers act as a barrier against corrosion and deterioration, preventing the ingress of moisture and harmful chemicals that may weaken the concrete over time. This enhanced durability ensures that the structure remains resilient and can withstand multiple seismic events throughout its lifespan. In summary, melt extract stainless steel fiber improves the resistance to seismic loading in concrete by enhancing its tensile strength, ductility, bond strength, and energy absorption capacity. By mitigating the propagation of cracks, distributing seismic forces more evenly, and increasing the overall durability, this reinforcement material significantly improves the seismic resistance of concrete structures, making them more resilient and safer in earthquake-prone areas.

- Q: How does melt extract stainless steel fiber affect the resistance of concrete to sulfate attack?

- The resistance of concrete to sulfate attack is positively influenced by the inclusion of melt extract stainless steel fiber. Sulfate attack arises from the reaction between sulfate ions found in soil or water and specific compounds in concrete, which results in the creation of expansive substances that can lead to the deterioration of the concrete. The incorporation of stainless steel fibers into concrete acts as a reinforcement material, enhancing its overall durability and resistance to various forms of degradation, such as sulfate attack. These fibers aid in improving the concrete's ability to resist the infiltration of sulfate ions and reduce the formation of detrimental expansive substances. The utilization of the melt extraction process in the production of stainless steel fibers ensures a high degree of purity and a uniform dispersion throughout the concrete matrix. As a result, the bonding between the fibers and the surrounding concrete is enhanced, resulting in a stronger and more resilient material. Moreover, the corrosion-resistant characteristics of stainless steel fibers make them highly effective in preventing concrete deterioration caused by sulfate attack. In contrast to other fiber types, stainless steel fibers do not corrode when exposed to sulfate ions. This corrosion resistance helps to maintain the integrity of the concrete, preventing the formation of cracks or other types of damage that may occur due to the expansion of sulfate products. To conclude, the addition of melt extract stainless steel fiber to concrete enhances its resistance to sulfate attack by improving its ability to withstand the infiltration of sulfate ions and reducing the formation of expansive substances. The corrosion-resistant properties of stainless steel fibers further contribute to the long-term durability and performance of concrete in sulfate-rich environments.

- Q: What is the typical aspect ratio of melt extract stainless steel fibers?

- The typical aspect ratio of melt extract stainless steel fibers is usually between 20:1 to 100:1.

- Q: How does the addition of melt extract stainless steel fiber affect the drying time of concrete?

- The drying time of concrete can be significantly impacted by the inclusion of melt extract stainless steel fiber. Concrete mixtures often incorporate stainless steel fibers to improve durability and enhance mechanical properties. One notable advantage of using stainless steel fibers is their ability to reduce drying shrinkage. As concrete dries, it typically undergoes shrinkage, which can result in cracks and structural problems. However, the addition of stainless steel fibers helps to restrain this shrinkage, resulting in a more controlled and uniform drying process. The presence of stainless steel fibers also promotes the formation of a more interconnected network within the concrete matrix. This network enhances the concrete's resistance to cracking and strengthens it overall. Consequently, the concrete can better withstand forces and stresses, even during the drying phase. Moreover, stainless steel fibers also aid in reducing plastic shrinkage cracking. This type of cracking occurs during the early stages of concrete drying, when the surface moisture evaporates faster than it can be replaced. By reinforcing the concrete, the stainless steel fibers help to mitigate this cracking, leading to a more efficient and stable drying process. In conclusion, the addition of melt extract stainless steel fiber can have a significant impact on the drying time of concrete. By reducing drying shrinkage, enhancing mechanical properties, and mitigating cracking, these fibers contribute to a more controlled and efficient drying process. This ultimately improves the overall performance and durability of the concrete structure.

- Q: Can melt extract stainless steel fiber be used in self-compacting concrete (SCC)?

- Indeed, melt extract stainless steel fibers are capable of being utilized in self-compacting concrete (SCC). SCC, a type of concrete that possesses high fluidity and is able to occupy and flow into even the most densely packed reinforcement areas without the need for vibration, often incorporates stainless steel fibers to augment its mechanical characteristics, including flexural strength, impact resistance, and toughness. The production of melt extract stainless steel fibers involves a melt extraction process, which guarantees consistent quality and uniform dispersion of fibers within the concrete matrix. These fibers exhibit exceptional resistance to corrosion and possess outstanding durability, rendering them suitable for employment in SCC, which is frequently employed in the construction of high-performance and long-lasting concrete structures. The inclusion of melt extract stainless steel fibers in SCC yields improvements in its ductility, crack resistance, and overall performance. These fibers function as reinforcement, supplying supplementary tensile strength to the concrete and diminishing the likelihood of cracking. Additionally, they aid in the control of shrinkage and the prevention of plastic shrinkage cracks. Moreover, melt extract stainless steel fibers contribute to the post-cracking behavior of SCC by heightening its resistance to cracking and ensuring the integrity of the concrete even subsequent to cracking. This is especially advantageous in scenarios where the control of cracks and the preservation of structural integrity are of utmost importance, such as in industrial flooring, tunnel linings, and precast elements. To summarize, melt extract stainless steel fibers can be effectively employed in self-compacting concrete (SCC) to enhance its mechanical properties, enhance crack resistance, and ensure long-term durability. The inclusion of these fibers in SCC can result in the creation of sturdier and more enduring concrete structures, rendering them a fitting choice for a variety of construction applications.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Melt Extract Stainless Steel Fiber Slit Sheet 330

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords