Melt Extract Stainless Steel Fiber Reinforced Concrete Wire with Glued Steel Fibers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland), Shandong, China (Mainland)

Model Number: GLUED, glued steel fiber

Material: Steel

type: steel fiber for concrete reinforcement

material: steel wire

shape: glued together in a row

appearance: clear and bright

Product features

1>steel fiber

2>tensile strength: >1000Mpa

3>wire diameter:0.5mm-1mm

4>standard: ASTM A820

5>20 years factory

hook ends steel fiber, Corrugated steel fiber,Wavy Steel Fiber, steel fiber reinforced, stainless steel fiber, etc.

steel fiber are for concrete construction, greatly improves concrete bonding,etc.

Specifications

length :20-60mm

diameter :0.5MM-1.2MM

tensile strengh:>1100Mpa

| diameter | length | tensile strength | |

| 0.5mm | 35mm | 1100Mpa | |

| 0.75 | 60mm | 1100Mpa | |

| 0.9 | 60m | 1100Mpa |

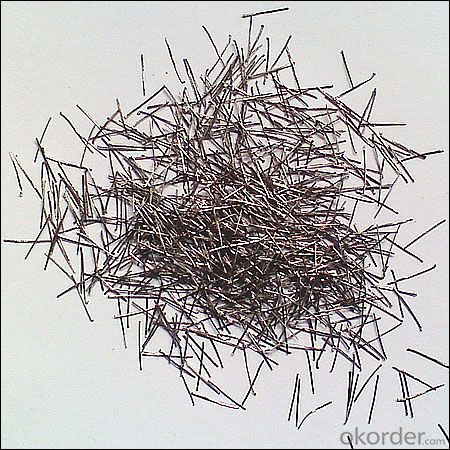

Picture

PP bag

any type

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

Steel Fiber Glued for Construction and Concrete Wire Diameter

- Q: What is the average length of melt extract stainless steel fiber?

- The average length of melt extract stainless steel fiber is typically around 50mm to 65mm.

- Q: How does melt extract stainless steel fiber affect the freeze-thaw resistance of concrete?

- Melt extract stainless steel fiber positively affects the freeze-thaw resistance of concrete by enhancing its durability and minimizing damage caused by repeated freezing and thawing cycles. The addition of these fibers helps to reduce cracking, improve tensile strength, and enhance the overall performance of concrete in harsh weather conditions.

- Q: What is the optimal dosage of melt extract stainless steel fiber in concrete?

- The optimal dosage of melt extract stainless steel fiber in concrete depends on various factors such as the specific application, desired performance characteristics, and the type of concrete mix being used. It is recommended to consult with a structural engineer or a concrete expert to determine the appropriate dosage that will meet the specific requirements of the project.

- Q: Can melt extract stainless steel fiber be used in marine environments?

- Indeed, melt extract stainless steel fiber is applicable for use in marine environments. Stainless steel is renowned for its exceptional resistance to corrosion, rendering it suitable for diverse marine applications. The melt extract stainless steel fibers are manufactured through a unique technique that guarantees superior tensile strength and longevity, enabling them to withstand the rigorous conditions encountered in marine settings, such as exposure to saltwater and elevated moisture levels. These fibers have the potential to be utilized in a variety of marine applications, including reinforcing concrete structures, marine coatings, and marine composites, to deliver heightened durability and resistance against corrosion.

- Q: Can melt extract stainless steel fiber be used in tunnel shotcrete applications?

- Yes, melt extract stainless steel fiber can be used in tunnel shotcrete applications. Stainless steel fibers are commonly added to shotcrete mixes to improve the overall performance and durability of the concrete. The addition of stainless steel fibers can enhance the tensile strength, impact resistance, and crack resistance of the shotcrete, making it suitable for tunnel applications where the concrete needs to withstand high pressures, vibrations, and potential ground movements. Melt extract stainless steel fibers are particularly beneficial due to their high tensile strength, corrosion resistance, and ability to disperse uniformly throughout the shotcrete mix. This ensures that the shotcrete has consistent reinforcement and can effectively withstand the harsh tunnel environment. Overall, melt extract stainless steel fiber is a reliable and effective choice for reinforcing shotcrete in tunnel applications.

- Q: Can melt extract stainless steel fiber be used in lightweight or low-density concrete?

- Certainly! Melt extract stainless steel fiber is a viable option for incorporating into lightweight or low-density concrete. The inclusion of these stainless steel fibers yields numerous advantages. Firstly, it heightens the overall robustness and endurance of the concrete, rendering it more impervious to cracking and shrinkage. Moreover, the fibers amplify the concrete's resilience against impact and abrasion, making it suitable for situations where the concrete may experience substantial loads or wear. In the case of lightweight or low-density concrete, the stainless steel fibers contribute to fortifying and steadying the material. They effectively distribute stress and load throughout the concrete, preventing the formation of cracks and enhancing its structural integrity. In addition, the stainless steel fibers can assist in managing shrinkage and minimizing the risk of cracking, which is particularly crucial in low-density concrete where shrinkage can be more prominent. Furthermore, melt extract stainless steel fibers boast corrosion resistance, thereby making them an appropriate choice for concrete exposed to harsh environmental conditions or in applications where the concrete comes into contact with corrosive substances. This corrosion resistance guarantees that the fibers will retain their strength and performance over time. In summary, incorporating melt extract stainless steel fiber into lightweight or low-density concrete can enhance its mechanical properties, bolster its durability, and provide superior resistance to cracking and shrinkage.

- Q: Can melt extract stainless steel fiber be used in concrete repair or rehabilitation?

- Concrete repair or rehabilitation can utilize melt extract stainless steel fiber. To enhance durability, strength, and resistance to cracking, stainless steel fibers are commonly incorporated into concrete mixes. Acting as reinforcement, these fibers reduce shrinkage and prevent crack formation. Furthermore, they bolster impact, abrasion, and corrosion resistance of the concrete. Melt extract stainless steel fibers undergo a specialized melting and extraction process, resulting in high-quality fibers with exceptional mechanical properties. During concrete batching, these fibers are typically added to ensure even distribution throughout the structure. In the context of concrete repair or rehabilitation, melt extract stainless steel fibers can reinforce damaged or deteriorated concrete. They restore structural integrity and prevent further degradation. Additionally, these fibers enhance the bond between repair material and existing concrete, ultimately improving the performance and longevity of the restored structure. It is crucial to adhere to specific guidelines and recommendations provided by manufacturers or industry standards when employing melt extract stainless steel fibers in concrete repair or rehabilitation. Proper dosage, mix design, and application techniques must be followed to achieve optimal performance and durability.

- Q: Can melt extract stainless steel fiber be used in architectural concrete applications?

- Yes, melt extract stainless steel fiber can be used in architectural concrete applications. Stainless steel fibers are often added to concrete mixtures to increase its strength, durability, and resistance to cracking. The melt extract stainless steel fibers are particularly effective in architectural concrete applications due to their high tensile strength and corrosion resistance. These fibers can help to reinforce the concrete, improve its structural integrity, and provide additional protection against potential damage from environmental factors or heavy loads. Moreover, the use of stainless steel fibers in architectural concrete can also enhance the aesthetic appearance of the finished product, as they can be easily polished to create a smooth and shiny surface. Overall, melt extract stainless steel fibers are a suitable choice for architectural concrete applications, offering both functional and aesthetic benefits.

- Q: How does melt extract stainless steel fiber improve the flexural strength of concrete?

- The flexural strength of concrete is improved by melt extract stainless steel fiber, which provides reinforcement throughout the material. When the stainless steel fibers are added to the concrete mixture, they are evenly distributed, creating a three-dimensional network within the concrete matrix. This network acts as a reinforcement system, enhancing the overall strength and durability of the concrete. The cracks that occur in concrete under load are effectively bridged by the stainless steel fibers, preventing their propagation and controlling their width. This bridging effect enhances the flexural strength of the concrete by increasing its ability to withstand bending and tensile stresses. Consequently, the concrete becomes more resistant to cracking, thereby enhancing its overall structural integrity. Additionally, the ductility of the concrete is also contributed by the stainless steel fibers. Ductility refers to the ability of a material to deform without fracturing. By reinforcing the concrete, the stainless steel fibers enhance its ductility, enabling it to absorb more energy before failure. This characteristic is particularly crucial in applications where the concrete is exposed to heavy loads or dynamic forces, such as in bridges, pavements, or industrial flooring. In conclusion, melt extract stainless steel fiber improves the flexural strength of concrete by reinforcing the material, bridging cracks, and enhancing its ductility. This reinforcement system increases the concrete's ability to withstand bending and tensile stresses, prevents the propagation of cracks, and improves its overall structural integrity.

- Q: What is the impact of melt extract stainless steel fiber on the shrinkage of concrete?

- The shrinkage of concrete can be significantly affected by the utilization of melt extract stainless steel fiber. To strengthen the concrete and prevent cracking, stainless steel fibers are commonly added to concrete mixes. During the curing process, concrete tends to shrink as water evaporates, leading to cracks and decreased structural durability. However, the inclusion of melt extract stainless steel fibers in the concrete mix effectively controls and minimizes shrinkage. These stainless steel fibers act as reinforcement within the concrete, promoting a more even distribution of stress and strain. This reinforcement restrains concrete shrinkage and provides greater resistance against cracking. The enhanced tensile strength of the concrete also limits overall shrinkage, resulting in a stronger and longer-lasting structure. Furthermore, the melt extract stainless steel fibers possess high corrosion resistance, further enhancing their effectiveness in mitigating shrinkage. This corrosion resistance ensures the fibers maintain their structural integrity over time, even in harsh environmental conditions. Overall, the integration of melt extract stainless steel fibers in concrete significantly reduces shrinkage and improves the material's overall performance. By minimizing cracking and enhancing durability, structures constructed with this type of concrete exhibit a longer lifespan and require less maintenance.

Send your message to us

Melt Extract Stainless Steel Fiber Reinforced Concrete Wire with Glued Steel Fibers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords