Melt Extract Stainless Steel Fiber - Loose Steel Fiber from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-MC

Material: Color Steel

certificated: ISO 9001

Specifications

We manufacture fibers according customer requirement

Steel fiber types includs,

a) Hooked ends steel fiber

b) Wave steel fiber

c) Needle-flat steel fiber

d) Wavy steel fiber

e) Glued steel fiber

f) Micro-steel fiber

g) stainless steel fiber

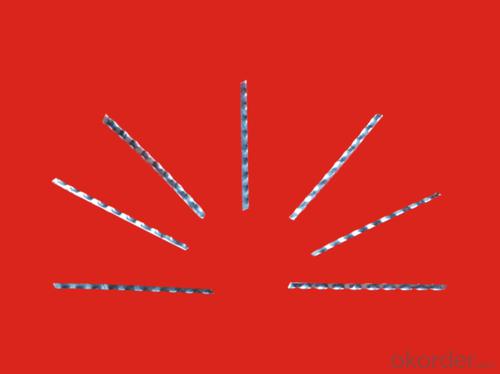

Picture

Steel fiber

Length :30--65 mm

Diameter :0.55--1.0 mm

Tensile strength: >1100 MPA .

Length :25--60 mm

Diameter :0.3--1.2 mm

Tensile strength: >1100 MPA .

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Is melt extract stainless steel fiber compatible with all types of admixtures?

- No, melt extract stainless steel fiber may not be compatible with all types of admixtures. Compatibility depends on the specific type of admixture and its chemical composition, as well as the intended application. It is important to consult with experts or manufacturers to determine the compatibility before usage.

- Q: What is the effect of melt extract stainless steel fiber on the compressive strength of concrete?

- Concrete can significantly benefit from the use of melt extract stainless steel fiber, as it enhances its compressive strength. By adding stainless steel fibers to the concrete mixture, the mechanical properties of the concrete are improved and its performance under compressive loading is enhanced. The incorporation of stainless steel fibers in concrete serves to increase its tensile strength, ductility, and toughness. These fibers act as reinforcement within the concrete matrix, providing additional strength and preventing crack propagation. When subjected to compressive forces, the fibers distribute stress more evenly throughout the concrete, resulting in a reduction in stress concentration points and an overall improvement in strength. Moreover, the presence of melt extract stainless steel fibers in concrete can enhance its resistance to temperature variations, shrinkage, and cracking. This is especially advantageous in areas where the concrete is exposed to extreme weather conditions or undergoes thermal cycling. Furthermore, the use of stainless steel fibers improves the durability and longevity of concrete structures. By inhibiting crack growth and propagation, the fibers contribute to a more durable and long-lasting concrete. Nevertheless, it is important to consider that the effect of melt extract stainless steel fibers on the compressive strength of concrete may vary depending on factors such as fiber content, aspect ratio, and distribution within the concrete matrix. Therefore, it is crucial to carefully assess these factors and conduct proper testing to determine the optimal fiber dosage and distribution for achieving the desired enhancement in compressive strength. In conclusion, melt extract stainless steel fibers positively impact the compressive strength of concrete by improving its mechanical properties, enhancing its resistance to cracking, and increasing its durability.

- Q: Can melt extract stainless steel fiber replace traditional steel reinforcement in concrete?

- Certain applications can see the substitution of traditional steel reinforcement in concrete with melt extract stainless steel fiber. Melt extract stainless steel fiber presents various advantages over traditional steel reinforcement, including increased durability, enhanced crack resistance, and improved corrosion resistance. These fibers, made from stainless steel, are typically incorporated into the concrete mixture during the mixing process. They contribute additional strength and support to the concrete, reducing the reliance on traditional steel reinforcement like rebar or mesh. One of the primary benefits of melt extract stainless steel fiber is its ability to enhance the durability of concrete structures. By evenly distributing stress throughout the concrete, the fibers decrease the likelihood of cracks and improve the overall strength of the structure. This aspect proves especially valuable in applications where the concrete will experience heavy loads or extreme conditions. Another advantage is the improved crack resistance offered by melt extract stainless steel fiber. Acting as reinforcement within the concrete, the fibers inhibit the propagation of cracks and minimize their size. Consequently, this leads to more durable and long-lasting concrete structures. Moreover, melt extract stainless steel fiber provides better resistance to corrosion when compared to traditional steel reinforcement. Stainless steel is renowned for its high level of resistance to corrosion, making it a dependable choice for applications involving exposure to harsh environments or chemicals. Nevertheless, it is crucial to note that melt extract stainless steel fiber may not be suitable for all concrete applications. The decision to replace traditional steel reinforcement with stainless steel fiber should be made based on factors such as specific project requirements, structural design, and the expected loads and conditions the concrete will endure. Consulting with a structural engineer or concrete expert is advised to determine the appropriateness of employing melt extract stainless steel fiber in a particular project.

- Q: Can melt extract stainless steel fiber be used in bridge deck applications?

- Yes, melt extract stainless steel fiber can be used in bridge deck applications. Melt extract stainless steel fiber is a type of reinforcement that is commonly used in concrete structures, including bridge decks. It is known for its high tensile strength, corrosion resistance, and durability, making it an ideal choice for applications where the structure is exposed to harsh environmental conditions, such as bridges. The stainless steel fibers are typically added to the concrete mixture, providing additional strength and crack resistance to the bridge deck. Additionally, melt extract stainless steel fiber can help improve the overall performance and lifespan of the bridge deck by reducing shrinkage, minimizing cracking, and enhancing structural integrity. Therefore, it is a suitable and commonly used reinforcement material for bridge deck applications.

- Q: What are the different types of melt extract stainless steel fibers available in the market?

- There are several types of melt extract stainless steel fibers available in the market, including straight fibers, crimped fibers, hooked-end fibers, and corrugated fibers. These fibers vary in their physical characteristics and are used in various applications such as reinforcement in construction, thermal insulation, and electrical conductivity.

- Q: How does melt extract stainless steel fiber enhance the flexural strength of concrete?

- The flexural strength of concrete is enhanced by the inclusion of melt extract stainless steel fiber, which reinforces the material throughout. When mixed into the concrete, the stainless steel fibers disperse evenly within the matrix, creating a network of reinforcement in three dimensions. These fibers play a crucial role in increasing the tensile strength of the concrete, which is especially important in applications involving bending and cracking forces. Similar to miniature reinforcement bars, the fibers prevent cracks from spreading and enhance the concrete's resistance to bending. Furthermore, the stainless steel fibers improve the bond between the concrete matrix and any aggregates or other reinforcement elements present. This strengthened bond facilitates the efficient transfer of stress and load, further improving the flexural strength of the concrete. The unique properties of stainless steel, including its high tensile strength, corrosion resistance, and ductility, make it an ideal material for enhancing the flexural strength of concrete. These fibers effectively bridge micro-cracks that may occur during the drying and hardening process, preventing them from developing into larger cracks under load. In summary, melt extract stainless steel fiber reinforces the concrete matrix, bolstering its ability to withstand bending and cracking forces. This improvement in flexural strength enables the construction of more durable and resilient concrete structures, particularly in applications where flexibility and crack resistance are vital, such as beams, slabs, and other structural elements.

- Q: Can melt extract stainless steel fiber be used in the construction of water storage tanks?

- Yes, melt extract stainless steel fiber can be used in the construction of water storage tanks. Melt extract stainless steel fiber is known for its high strength, durability, and corrosion resistance, making it an ideal material for applications where water is stored. It can withstand the harsh conditions and chemicals often found in water storage tanks, ensuring long-lasting performance and minimizing the risk of leaks or deterioration. Additionally, the addition of stainless steel fiber enhances the overall structural integrity of the tank, providing reinforcement and preventing cracking or failure. Overall, using melt extract stainless steel fiber in the construction of water storage tanks is a reliable and effective choice.

- Q: Can melt extract stainless steel fiber be used in architectural precast panels?

- Yes, melt extract stainless steel fiber can be used in architectural precast panels. These fibers provide increased strength, durability, and crack resistance to the panels, making them suitable for architectural applications.

- Q: What is the effect of melt extract stainless steel fiber on the workability of concrete?

- The addition of melt extract stainless steel fiber to concrete can have a significant effect on its workability. Stainless steel fibers are typically added to concrete to enhance its mechanical properties and improve its resistance to cracking, impact, and abrasion. One of the main benefits of using stainless steel fiber in concrete is that it increases its tensile strength and flexural strength. This means that the concrete becomes more resistant to bending or cracking under pressure, which is particularly important in structural applications. The incorporation of stainless steel fibers also enhances the overall durability and long-term performance of the concrete. However, the addition of stainless steel fibers can also have some drawbacks in terms of workability. The fibers can cause an increase in the viscosity of the concrete mix, making it more difficult to handle and place. This can result in a decrease in the fluidity and cohesiveness of the mix, making it harder to achieve the desired finish and surface texture. To overcome these challenges, it is important to carefully control the dosage and length of the stainless steel fibers used in the concrete mix. By optimizing the fiber content and distribution, it is possible to maintain a good balance between workability and the desired mechanical properties. In summary, the effect of melt extract stainless steel fiber on the workability of concrete is a trade-off between improved mechanical properties and potential challenges in handling and placing the mix. With careful consideration of the fiber dosage and mix design, it is possible to achieve a concrete mix that provides both enhanced performance and satisfactory workability.

- Q: Can melt extract stainless steel fiber be used in earthquake-resistant construction?

- Indeed, melt extract stainless steel fiber is applicable for earthquake-resistant construction. By infusing concrete with these fibers, it gains augmented strength and durability, effectively enhancing its resistance to cracking and structural impairment during seismic events. Acting as reinforcement, the fibers play a crucial role in distributing and dissipating the energy produced by seismic activity. Furthermore, the exceptional corrosion resistance of stainless steel fibers guarantees the longevity and efficiency of concrete structures in areas prone to earthquakes. Consequently, the integration of melt extract stainless steel fiber into construction materials can substantially heighten the earthquake resilience of buildings and infrastructure.

Send your message to us

Melt Extract Stainless Steel Fiber - Loose Steel Fiber from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords