Melt Extract Stainless Steel Fiber - Steel Fiber Loose Company CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Tianjin, China (Mainland)

Brand Name: CNBM

Model Number: 0.55

Material: Steel

Production Process: Cold drawn

Fiber Lengh: 35

Type: 1

Compressive Strength: >1200MPa

Aspect ratio: 63

Standard: ASTM A820M-11

Section Shape: Circular

Application: Concrete Reinforcement

Producing Area: Tianjin

Product Application: Industrial Floor

Specifications

| Diameter | 0.55 mm (0.217 in) | ||

| Length | 35 mm (13.780 in) | ||

| Aspect Ratio | 63 | ||

| Tensile strength | 1200 MPa | ||

| Type | Cold drawn Steel Fiber | ||

| End | Hooked-end Steel Fiber | ||

| Glued/Loose | Glued Steel Fiber | ||

| Bending Angle | 45°(min.30°) | ||

| Usage & Performance | Floor:Trafficked areas and Industrial floors | ||

| Shotcrete :Slope stabilization and Final lining | |||

| Precast concrete:Pipe and Railway sleepers | |||

| Packing | Standard Export Pallet Packing | Bag Packing | 20 kg/Bag,50 bags/Pallet |

| Bulk Packing | 1,000kg/ Bulk Bag | ||

| Loading Quantity | 20’GP | 20-25 Tonne/Tonnes | |

| 40’GP | 25-27 Tonne/Tonnes | ||

| 40’HQ | 25-27 Tonne/Tonnes | ||

| MOQ | 1 kg for trial order | ||

| Supply Ability | 10,000 Tonne/Tonnes per Year | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight | ||

| Certification | ISO9001:2000, CE, | ||

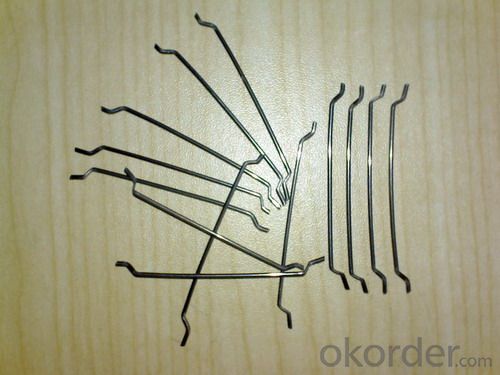

Picture

Steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: What is the typical fiber length of melt extract stainless steel fiber?

- The typical fiber length of melt extract stainless steel fiber is usually between 0.5 to 2 inches.

- Q: Can melt extract stainless steel fiber be used in bridge deck overlays?

- Yes, melt extract stainless steel fiber can be used in bridge deck overlays. These fibers are commonly used to enhance the durability and performance of concrete structures, including bridge decks, by providing additional reinforcement and improving crack resistance.

- Q: The use and types of steel fibers

- Steel fiber came out for a short time, but the field of application is more and more extensive, and accordingly, the varieties of steel fiber are increasing again.

- Q: Can melt extract stainless steel fiber be used in bridge decks or infrastructure projects?

- Yes, melt extract stainless steel fiber can be used in bridge decks or infrastructure projects. These fibers enhance the durability and structural strength of concrete, making it more resistant to cracking and improving its overall performance under heavy loads and harsh environmental conditions.

- Q: How does melt extract stainless steel fiber enhance the resistance to impact loads in concrete?

- Melt extract stainless steel fiber enhances the resistance to impact loads in concrete by providing additional reinforcement and improving the overall strength and durability of the concrete. The stainless steel fibers are uniformly distributed throughout the concrete mixture, forming a strong network that helps to absorb and distribute the impact forces more effectively. This reinforcement increases the flexural and tensile strength of the concrete, making it less susceptible to cracking or failure under impact loads. Additionally, the stainless steel fibers also act as a barrier against the propagation of cracks, further improving the concrete's resistance to impact loads.

- Q: Can melt extract stainless steel fiber be used in industrial chimney construction?

- Indeed, industrial chimney construction can incorporate melt extract stainless steel fiber. This particular fiber is renowned for its remarkable ability to withstand high temperatures, rendering it well-suited for usage in environments characterized by elevated temperatures, such as chimneys. By incorporating this fiber, the chimney structure can be fortified and its strength and durability enhanced. Moreover, melt extract stainless steel fiber also exhibits resistance to corrosion, a crucial attribute for chimneys that are exposed to diverse chemicals and pollutants. Ultimately, the utilization of melt extract stainless steel fiber in industrial chimney construction is bound to elevate the chimney's performance, lifespan, and safety.

- Q: Can melt extract stainless steel fiber be used in earthquake retrofitting?

- Yes, melt extract stainless steel fiber can be used in earthquake retrofitting. These fibers are known for their high tensile strength and excellent resistance to corrosion, making them ideal for reinforcing concrete structures. When added to concrete, they enhance its tensile strength and ductility, helping withstand seismic forces and improving the overall performance of the retrofitting process.

- Q: How does melt extract stainless steel fiber enhance the durability of concrete?

- Melt extract stainless steel fiber enhances the durability of concrete by providing reinforcement and improving its overall strength. When added to concrete, the stainless steel fibers distribute throughout the mixture, forming a three-dimensional network that helps to prevent cracks and improve the concrete's resistance to various types of stresses. The stainless steel fibers act as reinforcement, similar to traditional steel bars or mesh, but with the advantage of being more evenly distributed throughout the concrete. This reinforcement helps to resist tensile forces, reducing the likelihood of cracking and increasing the overall load-bearing capacity of the concrete structure. Furthermore, the stainless steel fibers also enhance the durability of concrete by improving its resistance to various environmental factors. They can help protect the concrete against corrosion caused by exposure to moisture, chemicals, and other aggressive substances. This corrosion resistance ensures the longevity of the concrete structure, reducing the need for frequent repairs or replacements. Additionally, the stainless steel fibers can also enhance the impact resistance and toughness of the concrete, making it more resistant to impact or dynamic loads. This is particularly beneficial in high traffic areas or structures that will be subjected to heavy loads or frequent impacts. In summary, melt extract stainless steel fiber enhances the durability of concrete by providing reinforcement, improving its resistance to cracking, enhancing its load-bearing capacity, protecting against corrosion, and increasing its impact resistance. These benefits result in a stronger, more durable concrete structure that can withstand various environmental factors and load conditions, ultimately extending its lifespan and reducing maintenance costs.

- Q: Does melt extract stainless steel fiber improve the flexural strength of concrete?

- Yes, melt extract stainless steel fiber can improve the flexural strength of concrete.

- Q: Can melt extract stainless steel fiber be used in architectural shotcrete applications?

- Yes, melt extract stainless steel fiber can be used in architectural shotcrete applications.

Send your message to us

Melt Extract Stainless Steel Fiber - Steel Fiber Loose Company CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords