Master Forge Aluminum Grill Sheets - PE Color Coated and Stucco Embossed Aluminum Coils (0.2~0.7mm)

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm

Color coated and embossed aluminum coils are widely used for decorations, freezer, refrigerator, central air conditioning and ventilation nozzles, mechanical equipment enclosures and so on.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

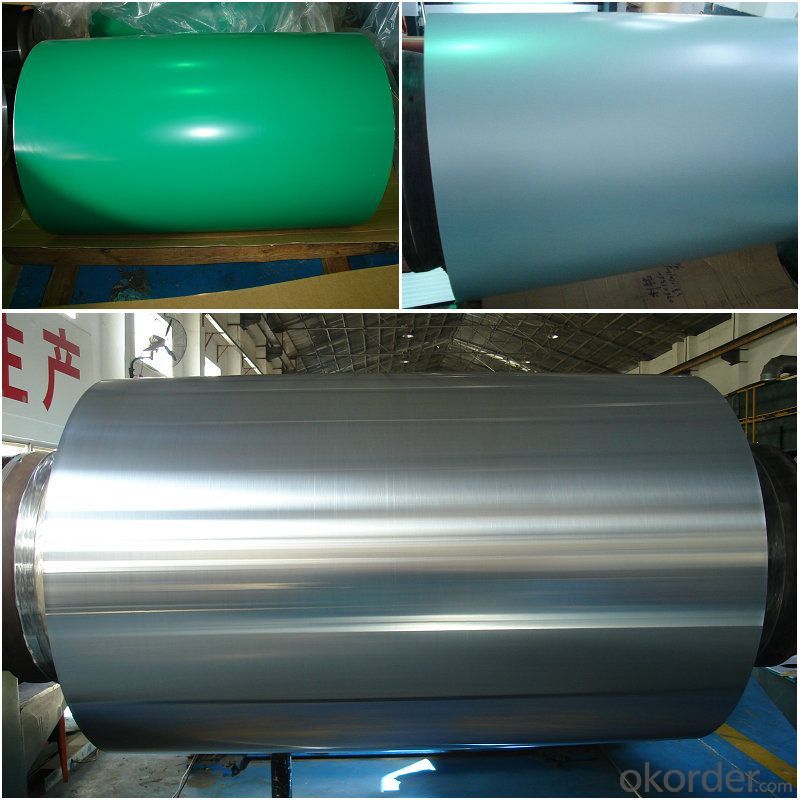

3. PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm Images

4. Specification of PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Are the aluminum sheets suitable for manufacturing architectural roof systems?

- Yes, aluminum sheets are suitable for manufacturing architectural roof systems. Aluminum is lightweight, durable, corrosion-resistant, and easy to work with, making it an ideal material for constructing roof systems in architectural projects.

- Q: What unique considerations or prerequisites are necessary when installing aluminum sheets?

- <p>When installing aluminum sheets, there are several special requirements to consider. First, ensure that the surface is clean, dry, and free of any debris to guarantee proper adhesion. Use appropriate fasteners designed for aluminum to prevent corrosion. Measure and cut the sheets accurately to fit the intended area, as aluminum can be prone to warping if not handled correctly. Additionally, consider the environmental conditions, such as temperature and humidity, which can affect the installation process. Always follow the manufacturer's guidelines for installation and safety precautions.</p>

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be used in food packaging. Aluminum is a common material choice for food packaging due to its excellent barrier properties, durability, and ability to maintain the freshness and quality of food products. It is also lightweight, recyclable, and resistant to moisture, odors, and UV light.

- Q: Can 101 aluminum sheets be used in the production of nameplates or tags?

- Yes, 101 aluminum sheets can be used in the production of nameplates or tags. Aluminum is a popular material choice for nameplates and tags due to its durability, lightweight nature, and resistance to corrosion. The 101 aluminum alloy, which is a commercially pure aluminum, offers excellent formability and workability, making it suitable for various manufacturing processes such as stamping, engraving, or etching. It can be easily cut, shaped, and customized to create high-quality nameplates or tags with clear and precise markings. Additionally, aluminum's ability to withstand harsh environments and its attractive appearance make it a preferred choice for many industries, including automotive, aerospace, electronics, and signage. Therefore, 101 aluminum sheets are a suitable material for the production of nameplates or tags.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: Can aluminum sheets be used as a substitute for steel in certain applications?

- Yes, aluminum sheets can be used as a substitute for steel in certain applications. Aluminum is a lightweight and versatile material that offers several advantages over steel. It has a high strength-to-weight ratio, meaning it can provide the same strength as steel while being significantly lighter. This makes aluminum sheets an excellent choice for applications where weight reduction is critical, such as in aerospace, automotive, and transportation industries. Additionally, aluminum is highly resistant to corrosion, which eliminates the need for additional protective coatings or treatments. This property makes aluminum sheets suitable for applications in marine environments or other corrosive conditions. Aluminum sheets also exhibit excellent thermal conductivity, making them ideal for applications that require heat dissipation, such as heat exchangers or radiators. Furthermore, aluminum is more malleable than steel, allowing for easier shaping and forming. This characteristic makes aluminum sheets suitable for applications that require complex or intricate designs. However, it is important to note that aluminum has a lower tensile strength compared to steel. Therefore, in applications that require high load-bearing capacities or structural integrity, steel may still be the preferred choice. In such cases, a careful evaluation of the specific requirements and trade-offs between weight, strength, and cost should be considered before deciding on using aluminum sheets as a substitute for steel.

- Q: The diameter of a hole drilled through aluminum at 22°C is 7.50 mm. Find the diameter and the area of the hole at 89°C.

- Aluminum okorder / So 7.50 * 22.2 * 10-6 * 89 = 0.0111555 mm diameter increase (should only report 3 sig figs, so 7.51 mm). The area is then pi / 4 * d^2 = 44.31017 (so 44.3) mm^2

- Q: Can aluminum sheets be used for lithographic printing?

- Yes, aluminum sheets can be used for lithographic printing. Lithographic printing, also known as offset printing, is a popular printing technique that involves transferring an image from a plate onto a rubber blanket and then onto the printing surface. Aluminum sheets are commonly used as the base material for lithographic plates due to their excellent durability, lightweight nature, and ability to hold fine details. The aluminum sheets used for lithographic printing are typically coated with a photosensitive emulsion, which allows the image to be transferred onto the printing surface with precision and accuracy. This makes aluminum sheets an ideal choice for lithographic printing, especially for high-quality and large-scale printing projects.

- Q: Explain how aluminum sheets can impact the longevity and robustness of a building's structure.

- <p>Aluminum sheets can significantly enhance the durability of a building due to their corrosion resistance, lightweight nature, and high strength-to-weight ratio. They are resistant to weathering, which protects the building from environmental damage, and they do not rust, reducing the need for maintenance and repair. Additionally, aluminum's malleability allows for the creation of various shapes and sizes, making it versatile for different architectural designs. Its recyclability also contributes to sustainability, reducing the overall environmental impact of construction.</p>

- Q: I am engaged in line cutting, because the cut aluminum plate conductive block wear more fierce, molybdenum wire is often broken card, I do not know that heroes have unique skills, say, we share. Thanks.

- The most effective way is to directly use the cutting aluminum electrode wire. Solve the problems of burning, conducting blocks, breaking wires, cutting workpieces and so on. Since the conductive system of machine tool of high and modified carbon brush structure is not the same, will cause the machine not successful,

Send your message to us

Master Forge Aluminum Grill Sheets - PE Color Coated and Stucco Embossed Aluminum Coils (0.2~0.7mm)

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords