Manufacture Of Rotary Transportation Pump

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10000 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of rotary transportation pump:

Rotary transportation pump is the key equipment for the mechanise production of grc

products, this is a new technique which is referenced from foreign well rounded technique, developed unaided, and suit for the sweeping production of grc. It had used wireless actiyator and grc carriers feeder, it have so many excellences such as feeder continuous, easy handle, high production efficiency, good roduction quality, etc.

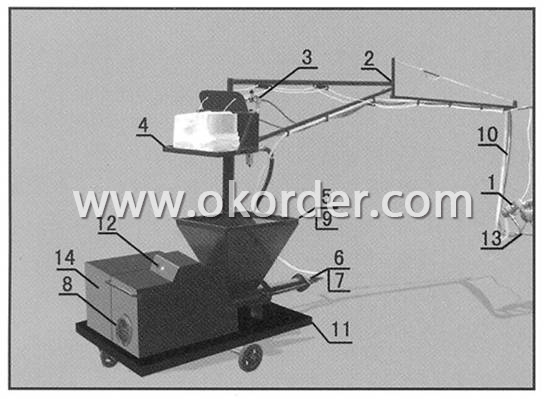

Construction and function of rotary transportation pump:

1. Gunjet: you can select coaxial gunjet or heteraxial gunjet or premixed gunjet or long gunjet as your need.

2. Cantilever: cantilever have two parts, each part is 2 meters, total is 4 meters, so, it can work in a round area, which use eject machine as center and have 4 meters radius. It used for hang the material pipeline and constringented air pipeline, and transfer them to gunjet position.

Working instruction for rotary transportation pump

3. Air element: it contain the air filter and reductor and oil mist element etc. It is used to filtrate the constringented air and adjust the constringented air pressure and lubricate the pneumatic motor.

4. Yarn spindle platform, it can be revolving with cantilever synchronous to avoid yarn twist. Tundish: it is used to reserve material.

5. Spindle: it is a key element with rotor for ls002, their relative movement can export the products continuously.

6.Rotor: it is a key element with spindle for ls002, their relative movement can export the products continuously.

7. Wireless actiyator: this is the power origin, you can adjust the products sendout via it’s rotate speed.

8. Beater: churn the material and send it to the entrance of spindle and rotor.

9. Material pipe: it can make the material transferred from assistant spindle/rotor to gunjet.

10. Pedestal: it is moveable.

11. Control equipment: use this to control the machine.

12. Windpipe: supply constringented air for gunjet.

13. Cover: protect the wireless actiyator

- Q: GRC cement products have cracks, what are the reasons?

- There are many reasons for cracks in GRC cement products, such as thermal expansion, cold contraction, or, in other words, the disadvantages of GRC components.

- Q: What is the GRC railing and what is the GRC railing knowledge?

- The protective window railing and closer to the corridor in the railing, set more appropriate corridor railings, stair railing in separate columns without quota, the quota shall be approved by the staircase contains a column

- Q: What are lightweight partitions and lightweight partition materials?

- Autoclaved aerated concrete slabs of autoclaved aerated concrete slab is made of cement, lime, silica sand as the main raw materials according to the requirements of different number of structure configuration to add embalmment reinforcing mesh is a lightweight porous new green building materials. With high temperature and high pressure, steam curing reaction production with porous crystalline autoclaved aerated concrete slab, the density is lower than the general cement materials, and has good fire resistance, fire resistance, sound insulation, heat insulation, insulation and other incomparable performance.

- Q: GRC composite column, which is better?

- However, there is a point to remember to mechanical injection molding process, which, if alkali glass fiber, and its alkali resistant glass fiber weight of about 5%, the general 4.8%--5.5% (this can be calculated by their own checks).

- Q: Daming Palace building materials wholesale GRC European style component where?

- In the domestic GRC European components do better, in Nanning over there, you can transport to your place, but a small amount of local customization is still good, the cost will be low.

- Q: What material is GRC?

- GRC also known as GRC components, and its Chinese name is glass fiber reinforced cement, simple to say that the external wall decoration materials, or wall decoration hanging board, mainly used in European style building exterior wall decoration. There are many kinds of GRC at present, such as GRC relief, GRC column, GRC window sleeve, GRC line and so on.If the project is wide Friends of the GRC can do in the engineering goods accessories temporary factory, which can be mounted.

- Q: What is the working principle of the mortar pump?

- 7, the piston 8 reversing valve at the same time, S 10 also reversing, the movable end and conveying cylinder 6 is 6 cylinder in the mortar conveying push 8 piston, enter S tube valve 10 is pressed into the discharge port 14; at the same time in the piston 7, conveying cylinder 5 inhalation of mortar, sent in preparation for the next step pressure. Thus, the mortar is pressed from the hopper to the conveying pipe, and this process is called pumping".

- Q: What is the best type of cement used in plain GRC components? What's the best filler? How dose glass fiber be controlled?

- Polymer: usually the added polymer is acrylic emulsion, that is acrylate copolymer emulsion.Admixture: usually selectively adding superplasticizer, superplasticizer, retarder, early strength agent, antifreeze, anti rust agent and other additives containing products: when the steel reinforcement or steel embedded parts, do not use calcium chloride based additives.Other materials: selectively adding some pozzolanic active materials to improve the overall properties of GRC products, such as strength, impermeability, durability, etc.. For more details.

- Q: How many useful years does the GRC art component have?

- GRC components of the service life and its own quality and workmanship are related, quality and workmanship better, of course, the longer the use of the industry average is 30 years, there are 50-70 years of use.

- Q: GRC what's the use of imitation wood?

- It can be used as GRC finished generic wood decoration materials used, GRC imitation wood than wood durability, wood decay, and GRC does not use wood is generally 20-30 years Guangyou GRC can be used for 50 years, so the two are not the same.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang PORT |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Manufacture Of Rotary Transportation Pump

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10000 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches