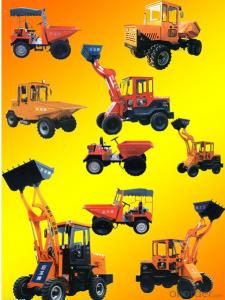

CMAX LOADER SERIE - BACKHOE LOADER - 3CX -15 super

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The JCB 3CX-15 Super is the world’s number one backhoe loader (along with the JCB 4CX). The 3CX-15 Super is a product of JCB’s efficient design philosophy, responding to today’s fluctuating fuel prices and environmental concerns with class-leading efficiency and low running costs. In short, we’ve applied innovative technologies to squeeze the absolute maximum out of every drop of fuel on the JCB 3CX 15 Super.

The result? In typical roading, loading, excavating and idle cycles, the 3CX-15 Super JCB backhoe loader, equipped with a powerful 109hp (81kW) EcoMAX engine, delivers an average fuel saving of up to 16%, plus lower emissions and noise levels. And, with extended periods between fill ups, you benefit from a longer, more productive working day.

But the efficiency (and other) benefits certainly don’t end there on a JCB 3CX-15 Super.

The JCB 3CX-15 Super is designed to enable fatigue-free, productive day-long working. The cab is rubber-mounted and isolated for low noise and vibration.

A JCB 3CX-15 Super cab is inspired by the automotive industry for familiarity. A heated air suspension seat, heated front windshield, and a hot beverage machine are just some of the quality features you can find within.

Ergonomic seat-mounted excavator-style controls – with optional excavator-style backhoe and loader servo controls – provide fingertip control, great comfort and excellent manoeuvrability.

For more comfort and less material spillage, the 3CX-15 Super’s Smoothride System (SRS) minimizes bounce during travel. You can quickly reset your shovel to the digging position with our return-to-dig feature too.

High back-off brakes reduce viscous drag during roading and rehandling, which improves economy by up to 1%.

The optional handheld tool circuit means you can increase versatility by using your 3CX-15 Super as a power source for handheld tools, such as drills, breakers, cutters and even water pumps.

JCB 3CX-15 Super backhoe loaders are quiet places to work, both inside and out – particularly the 109hp (81kW) models, which are the quietest in the industry.

Controls on the 3CX-15 Super feature an LCD panel detailing machine hours, service information fuel level and system warnings. A 360° view through tinted windows aids comfort, productivity and safety.

Our innovative scoop design one-piece rear windscreen allows JCB 3CX-15 Super operators to see right into the trench when excavating.

The 3CX-15 Super's new EcoMAX engine is designed, tested and built by JCB to work perfectly with JCB axles and gearboxes. T4 Final compliant EcoMAX produces power and torque at around 1500 rpm for responsiveness and fuel-efficient matching of the transmission and hydraulics.

Because the JCB EcoMAX doesn’t use exhaust after-treatment, it doesn’t need costly heat-resistant lube oils, saving servicing costs. And, because EcoMAX can be adapted to run on lower-grade fuels, Backhoes are resalable across different territories, which boost residuals.

JCB 3CX-15 Super engines are tried and tested. We’ve built 200,000 DIESELMAX engines since 2004, and we’ve tested the JCB EcoMAX for 110,000 hours in 70 different machines across the toughest applications and environments.

For ultimate loading performance, productivity and roading efficiency, the JCB 3CX’s EcoMAX engine delivers as much as 109hp (81kW) and 381 lbf (516 Nm) of torque.

JCB’s unique TorqueLock system is standard-fit on all 109hp (81kW) Powershift 3CX-15 Super models. Combined with our optional 6-speed Autoshift transmission, it can help save up to 25% on fuel and 10% on road travel time.

Limited slip differential gives a JCB 3CX-15 Super superior traction and performance, as well as reduced tire wear.

The 3CX-15 Super JCB backhoe loader is fitted with EcoRoad technology to provide the highest efficiency and productivity levels when roading. Fuel consumption is reduced, while machine speed and working area are increased by up to 10%.

- Q: GRC light partition board installation scheme for construction of hydropower pipelines

- GRC lightweight partition board is a new type of wall material developed in recent years. It can eliminate longitudinal cracks as long as it is built according to the order of requirement and new technology of interlocking joint is applied. Therefore, GRC lightweight partition board is one of the ideal materials for building energy conservation and wall reform, and has been widely used in engineering.

- Q: What is a GRC pile composite foundation?

- CFG pile is English Cement Fly-ash Gravel acronym, meaning cement fly ash gravel pile, composed of gravel, stone, sand, fly ash cement mixed with water, the variable strength pile with certain strength made pile with various machinery. CFG pile is a kind of low strength concrete pile. It can make full use of the bearing capacity of the soil between the piles, and transfer the load to the deep foundation. It has better technical performance and economic effect.

- Q: GRC jet equipment prices?

- We offer a full set of GRC injection equipment at 16800 yuan

- Q: What is the standard of ASTM a283 GRC?

- ASTM a283: American laboratory standard number "a283""Gr c:grade C, this is the steel grade gr (grade) B is B grade steel, equivalent to the domestic Q 235 steel, C is C pole steel, specific equivalent to domestic which kind of steel, check it yourself, I remember not too accurate

- Q: What is GRC in building engineering?

- Glass fiber reinforced cement (GRC)GRC is made of alkali resistant glass fiber as reinforcing material, the low alkalinity sulphoaluminate cement as binder and adding suitable aggregate to form the substrate, through injection, mould casting, extrusion, flow and other production process and made of lightweight, high strength and high toughness, multifunctional inorganic composite material. The use of lightweight GRC material partition board, insulation board, wall board, decoration series products, grid slab, ventilation Road, granary, rigid roofing and other dozens of products have been widely used in construction engineering, civil engineering, agriculture and Animal Husbandry Fishery etc..

- Q: What about the air leak in the flue?

- There are many kinds of problems. See where they leak.1, if the valve leaks, you need to remove the ceiling to check the valve.2, if the flue leaks, it is necessary to repair the loopholes.

- Q: GRC how should the lines be fixed?

- Accordingly. What project quantity sets what quota, find the amount of project quota that you need first.

- Q: Boiler flue cleaning with hydraulic or mechanical cleaning?

- Water washing, machinery can cause damage!

- Q: What material is GRC?

- GRC also known as GRC components, and its Chinese name is glass fiber reinforced cement, simple to say that the external wall decoration materials, or wall decoration hanging board, mainly used in European style building exterior wall decoration. There are many kinds of GRC at present, such as GRC relief, GRC column, GRC window sleeve, GRC line and so on.If the project is wide Friends of the GRC can do in the engineering goods accessories temporary factory, which can be mounted.

- Q: How many useful years does the GRC art component have?

- GRC components of the service life and its own quality and workmanship are related, quality and workmanship better, of course, the longer the use of the industry average is 30 years, there are 50-70 years of use.

Send your message to us

CMAX LOADER SERIE - BACKHOE LOADER - 3CX -15 super

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches