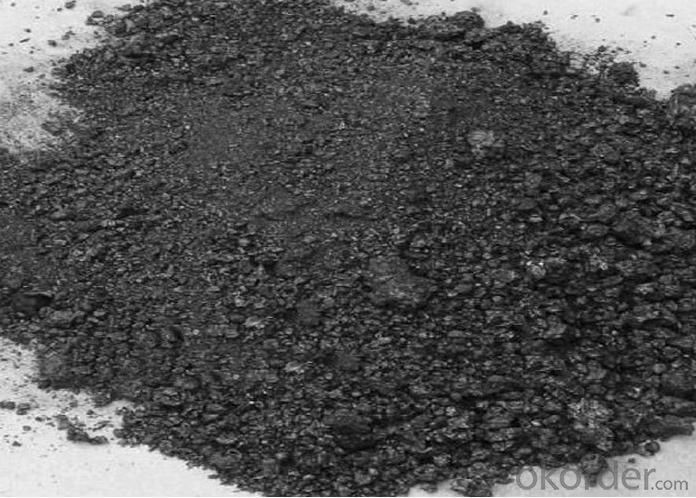

Low Sulphur Calcined Petroleum Coke CPC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Metric Tons m.t.

- Supply Capability:

- 300000 Metric Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Low Sulphur Calcined Petroleum Coke CPC

1) good quality,low sulfur

2) advanced production facilities

3) competitive price

Advantage of Low Sulphur Calcined Petroleum Coke CPC

It is made from green coke in calcining pot under high temperature. It is widely used for carbon addictive and metallurgy. Our CPC has stabe performance and strong conductivity with copetitive price. We have complete production lines with advanced automatic equipements and strict quality control systerm.

At present, it has been exported to many countries all over the world, such as America, Australia, India, Iran, Russia etc.

Packing details of Low Sulphur Calcined Petroleum Coke CPC

1) jumbo bags for 20 FCL

2) in bulk

- Q: Jiqi gypsum block industry standard JC / T698-. to the word version, thank you! The The Building industry industry standards

- This standard applies to the production and inspection of Portland cement and ordinary Portland cement

- Q: I plant is the production of building materials, and how to contact the design institute, so that the design institute in the design of our factory products. We have a design promotion fee

- You directly related to the people to find the design institute, or call, or personally go to the design institute to promote your building materials Caesar

- Q: Is the ceramsite concrete block and cement brick the same product?

- Autoclaved aerated concrete block is made of calcium powder (such as cement, lime) and siliceous materials (such as sand, fly ash Fu Tai Ju Gao Gao Dian Dian poke top pull ash, slag) Air-entraining, agitating, pouring, inflating, pre-cutting, and then by high-pressure steam curing porous silicate block

- Q: What are the causes of wall cracks in autoclaved aerated concrete blocks?

- Wall masonry too fast, plastering layer is not good, a plaster is too thick

- Q: 240 thick mu50 aerated autoclaved fly ash aerated concrete block size

- When the block is used as the main material of the building, its radionuclide limit should meet the requirements of "limited radionuclide for building materials" (GB6566-2010) When the radioactive specific activity of natural radionuclide radium- thorium-232 and potassium-40 in the main body of the building satisfies IRa≤10 and Ir≤1 the production and sales range is not restricted If the radioactivity specific activity of the natural radionuclide radium- thorium-232 and potassium-40 is more than 25%, the production and sales range of IRa≤10 and Ir≤13 are not affected by the limit Ministry of Finance, Environmental Protection Administration Document "Treasury [2006] No 90" provides that: state organs at all levels, institutions and organizations with financial funds to purchase, to give priority to the procurement of environmental labeling products, shall not be hazardous to the environment and human health product (HJ / T207-2005) standard, the main technical contents are as follows: waste and industrial by-products used in products (such as straw, wood chips, slag, fly ash, Coal gangue, gypsum, etc) content should be greater than 35%

- Q: Near the large building materials market, downstairs is the building materials market facade, I heard that building materials have radiation, living upstairs affect it? More

- Poor quality paint paint and the like products are not environmentally friendly, organic solvents volatile harmful to the body, and the big core board, MDF and other formaldehyde and more, how much dust, when it comes to radiation, with fly ash block Stare at the pet falter both pet smoked and will have, may lead to leukemia, recommended from the building materials market far point. Noise will not say, can hear.

- Q: What is the specific difference between steam-free foam and autoclaved concrete blocks? What are their strengths and weaknesses? Free foam brick production in the easy problems

- Free foam foam brick strength of the main role of cement, many construction sites are cement paste; small investment is the biggest advantage of steam-free foam brick

- Q: What is the role of blocks and mortars in masonry structures?

- The role of blocks and mortars in masonry structures is as follows: masonry and concrete are similar. Block is the concrete coarse aggregate (gravel, rubble), mortar is cement in the cementing material. The mortar binds the blocks together and works together. Mortar: brick used in the construction of the adhesive material, by a certain percentage of sand and cementing materials (cement, lime paste, clay, etc.) add water and into, also known as mortar, but also for mortar. Mortar is made of cementitious material (cement, lime, clay, etc.) and fine aggregate (sand) mixed with water. Commonly used cement mortar, mixed mortar (or called cement lime mortar), lime mortar and clay mortar.

- Q: What are the subjects of the exam? Are there any questions? Thank you

- The basic content of the project (the concept of projection, the three sides of the projection and the point of the projection of the basic knowledge of the basic knowledge of the project, (The basic model, positioning axis and the construction of the map to read the contents of reading);

- Q: Bathroom wall with what brick masonry, there is no specification requirements, what specific specifications more

- No specific requirements, there is little if the use of gas block, then asked to pour no less than 150mm high concrete belt, to prevent the filling block of water, affecting the finishes

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 1995 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | ISO 9001: 2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Sulphur Calcined Petroleum Coke CPC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Metric Tons m.t.

- Supply Capability:

- 300000 Metric Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords