Monolithic Refractory Castable - Low Cement Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chinese Low Cement Refractory Castable

Product Description:

Refractory castable is a type of unshaped refractory material. It is made of refractory aggregate, refractory powder, binders and other additives. It is loose, and highly liquid, cast and vibration molded, and can use directly or used after adding the appropriate water or other liquid. It is one of the new types of refractory materials that don't need calcination.

Product Features:

· High refractoriness, High refractoriness under load

· High density, low porosity

· Good slag resistance and corrosion resistance

· High strength and wear resistance

· Good resistance to flake performance

· Good thermal shock stability

· Scouring resistance

· Good hot strength

Product Applications:

Widely used in various kiln linings, such as boilers, blast furnace hot blast stoves, heating furnaces, ceramic kilns, heat treatment furnaces, incinerators, re-circulating fluidized bed furnaces and chemical industry and construction industry furnaces.

Product Specifications:

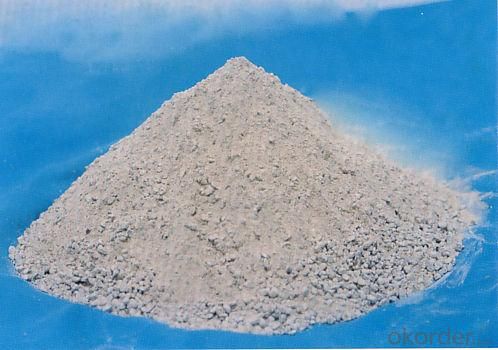

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What are Abrasion Resistant Coatings?

A3: ARC's abrasion resistant coatings guard against the severe wear and erosion that can chip away your plant's bottom line. These high-performance coatings protect new equipment as well as rebuild worn equipment at a fraction of traditional replacement costs.

- Q: How does the addition of melt extract stainless steel fiber impact the flowability of concrete?

- The addition of melt extract stainless steel fiber improves the flowability of concrete by enhancing its workability and reducing segregation. The fibers act as reinforcement, increasing the cohesiveness and viscosity of the concrete mix. This results in a more uniform and consistent flow, allowing for easier placement and better consolidation of the concrete.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced polymer (FRP) composites?

- Yes, melt extract stainless steel fiber can be used in fiber-reinforced polymer (FRP) composites. The addition of stainless steel fibers enhances the mechanical properties and durability of the composite material, making it suitable for various applications such as construction, automotive, and aerospace industries.

- Q: How do monolithic refractories help in reducing energy consumption in iron and steel production?

- Monolithic refractories play a vital role in the reduction of energy consumption in iron and steel production. These refractories are heat-resistant materials utilized to line the walls and floors of furnaces and other high-temperature equipment. One of the main ways monolithic refractories aid in energy reduction is through their exceptional thermal insulation properties. These materials possess low thermal conductivity, which effectively minimizes heat loss from the furnace or equipment. By keeping heat loss to a minimum, monolithic refractories help maintain a consistent and high temperature inside the furnace, resulting in enhanced energy efficiency. This allows for better utilization of generated heat, reducing the need for additional energy input and ultimately leading to energy savings. Additionally, monolithic refractories exhibit high thermal stability and resistance to thermal shock. This enables them to withstand the extreme temperatures and rapid temperature changes frequently encountered in iron and steel production processes. By having a robust and dependable lining, these refractories prevent heat leakage and ensure efficient heat transfer to desired areas, reducing energy wastage. Furthermore, monolithic refractories contribute to energy reduction by resisting chemical attack and erosion. In iron and steel production, furnaces and equipment linings are exposed to aggressive substances like molten metal, slag, and gases. Monolithic refractories exhibit excellent resistance to these corrosive elements, prolonging their lifespan and reducing the need for frequent repairs or replacements. This not only saves energy required for maintenance but also avoids production interruptions and associated energy losses. In conclusion, monolithic refractories aid in the reduction of energy consumption in iron and steel production by providing effective thermal insulation, withstanding extreme temperatures, and resisting chemical attack. By optimizing heat management and extending equipment durability, these refractories significantly contribute to energy efficiency and cost savings in the industry.

- Q: How long is the lifespan of monolithic refractories in iron and steel applications?

- The lifespan of monolithic refractories in iron and steel applications can vary depending on several factors such as the specific type of refractory material used, the operating conditions, and the maintenance practices. However, on average, monolithic refractories in iron and steel applications can last anywhere from a few months to several years.

- Q: How does melt extract stainless steel fiber improve the durability of tunnel linings?

- Enhanced reinforcement and resistance to deterioration are achieved in tunnel linings through the use of melt extract stainless steel fiber. Micro-reinforcement is provided by these stainless steel fibers when they are added to the concrete mixture used for tunnel linings, resulting in improved strength and durability for the structure. The ability of melt extract stainless steel fiber to enhance the tensile strength of the concrete is a significant benefit. Tunnels experience various forces and stresses, such as ground movement, vibrations, and water pressure. By reinforcing the concrete with stainless steel fibers, the tunnel linings become more resistant to cracking and spalling, which could compromise the integrity of the structure. In addition, the corrosion-resistant properties of stainless steel fibers make them ideal for tunnel applications. Tunnels often face harsh environments, including high humidity, chemical exposure, and saltwater intrusion. These conditions can lead to the corrosion of the reinforcement within the concrete, resulting in degradation and reduced durability. However, the corrosion resistance of stainless steel fibers helps prevent this deterioration, ensuring that the tunnel linings remain structurally sound for a longer period. Furthermore, melt extract stainless steel fibers reduce the risk of fire damage, thus improving the durability of tunnel linings. Tunnels are susceptible to fire incidents, which can significantly weaken the concrete and compromise the safety of the structure. The stainless steel fibers serve as a reinforcement that can withstand high temperatures, preventing the concrete from rapidly losing its strength during a fire. This increased fire resistance enhances the overall durability and safety of the tunnel linings. In conclusion, melt extract stainless steel fiber enhances the durability of tunnel linings by improving tensile strength, corrosion resistance, and fire resistance. By reinforcing the concrete and protecting it from cracking, corrosion, and fire damage, these stainless steel fibers ensure that tunnel linings can withstand the various challenges they may encounter, ultimately extending their lifespan and enhancing the overall safety of the tunnels.

- Q: Can melt extract stainless steel fiber be used in industrial flooring applications?

- Yes, melt extract stainless steel fiber can be used in industrial flooring applications. It provides additional reinforcement and durability to the flooring, making it suitable for heavy-duty industrial environments.

- Q: Is melt extract stainless steel fiber compatible with all types of concrete additives?

- No, melt extract stainless steel fiber may not be compatible with all types of concrete additives. Compatibility depends on the specific type and properties of the additives used. It is important to consult with manufacturers and conduct compatibility tests to ensure proper performance and compatibility when using melt extract stainless steel fiber with concrete additives.

- Q: How do monolithic refractories help in enhancing the durability of iron and steel equipment?

- Monolithic refractories play a vital role in increasing the durability of iron and steel equipment. They offer high resistance to extreme temperatures, chemical attack, and mechanical wear. Unlike traditional brick or castable refractories, monolithic refractories are made from a single, uniform material, making them stronger and more reliable. The ability of monolithic refractories to withstand high temperatures is crucial in iron and steel manufacturing processes. They can endure temperatures above 3000°F (1650°C) without losing their structural integrity, preventing premature equipment failure. This thermal resistance helps maintain the shape and structure of the refractory lining, ensuring efficient and consistent equipment performance. In addition to their heat resistance, monolithic refractories also possess excellent chemical resistance. This is important because iron and steel equipment often comes into contact with corrosive substances like molten metal, slag, and various chemicals. The ability of monolithic refractories to resist chemical attack prevents degradation and erosion of the equipment's lining, extending its lifespan. Moreover, monolithic refractories provide exceptional mechanical strength and wear resistance. The equipment is constantly exposed to abrasive materials, physical impacts, and mechanical stress, which can cause severe damage. However, the dense and compact structure of monolithic refractories makes them highly resistant to mechanical wear, minimizing the risk of erosion and spalling. The flexibility and versatility of monolithic refractories further enhance the durability of iron and steel equipment. They can be easily molded, shaped, and installed in complex geometries, ensuring a tight and precise fit. This eliminates the formation of gaps or weak points, which could result in thermal or chemical leakage, reducing the risk of equipment failure. In conclusion, the use of monolithic refractories significantly improves the durability of iron and steel equipment. They offer exceptional resistance to high temperatures, chemical attack, and mechanical wear. By ensuring the longevity and reliability of the equipment, monolithic refractories enhance operational efficiency and cost-effectiveness in the iron and steel industry.

- Q: What is the effect of melt extract stainless steel fiber on the durability of shotcrete?

- The use of melt extract stainless steel fiber in shotcrete can greatly enhance its durability. Shotcrete is a popular construction material that is typically sprayed onto surfaces, providing a strong and durable concrete layer. However, shotcrete can be prone to cracking and spalling over time, especially in harsh environmental conditions or under heavy loading. By incorporating melt extract stainless steel fiber into the shotcrete mix, the overall durability of the material is significantly improved. These fibers act as reinforcement, providing added strength and crack resistance to the shotcrete. The stainless steel fibers help to distribute stress and prevent the formation and propagation of cracks, thus enhancing the overall durability and lifespan of the shotcrete. The unique properties of melt extract stainless steel fibers make them ideal for shotcrete applications. They have high tensile strength, which allows them to effectively resist crack formation and propagation. Additionally, stainless steel fibers exhibit excellent corrosion resistance, even in aggressive environments, further enhancing the durability of the shotcrete. The addition of melt extract stainless steel fibers also improves the overall structural integrity of shotcrete. The fibers help to increase the flexural and shear strength of the material, making it more resistant to loading and impact forces. This enhanced structural integrity ensures that the shotcrete can withstand heavy loads, vibrations, and other external forces without significant damage or degradation. Overall, the incorporation of melt extract stainless steel fiber in shotcrete significantly improves its durability by enhancing crack resistance, corrosion resistance, and structural integrity. This results in a longer lifespan and reduced maintenance requirements for shotcrete structures, making it a highly beneficial addition to the construction industry.

- Q: How do monolithic refractories improve the performance of iron and steel furnaces?

- Monolithic refractories, unlike traditional brick-based refractories, offer several advantages that enhance the performance of iron and steel furnaces. Firstly, their seamless design eliminates joints and seams, reducing the risk of thermal shock and leakage, leading to improved insulation and energy efficiency. Additionally, monolithic refractories have higher thermal conductivity and superior resistance to chemical attacks, ensuring longer furnace life and reduced maintenance costs. Their ability to be easily shaped and installed also allows for better lining optimization, promoting better heat transfer and uniform temperature distribution within the furnace. Ultimately, monolithic refractories contribute to increased productivity, reduced downtime, and overall improved performance of iron and steel furnaces.

Send your message to us

Monolithic Refractory Castable - Low Cement Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords