Carport Solar Mounting System with Large Scale Ground Joint Horizontal Axis Tracking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

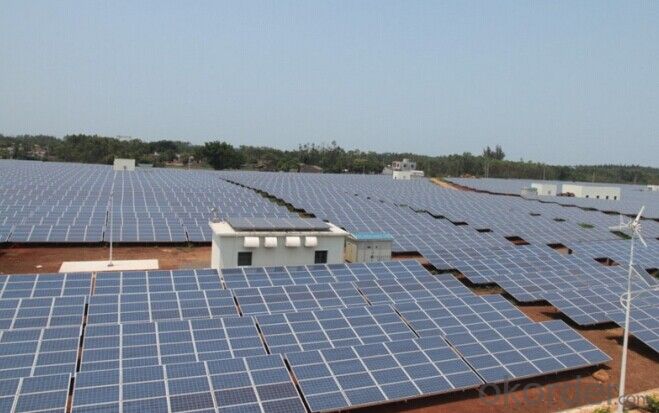

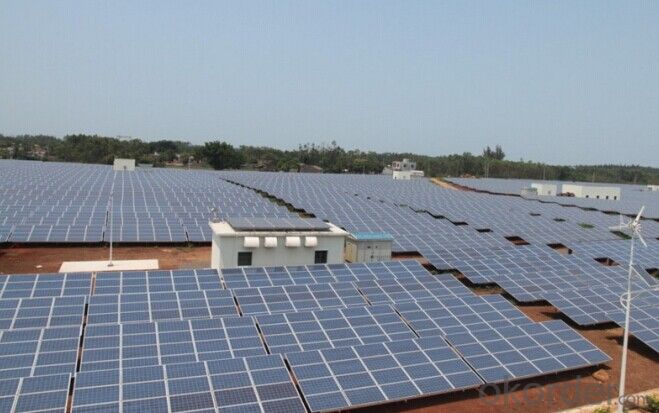

Large scale ground joint horizontal axis tracking system

Tracking system used in solar plant

Performance Feature:

single set horizontal axis tracking system is that:

1. the advantage conpared with the fixed mounting system.cover the same area as the fixed mounting system.

2. power generating can be increased by 10-30%.the foundation scale is the same as the fixed mounting system.

3. the comprehensive costs are much lower than the fixed mounting system.

4. suitable fooe the min-low latitude areas and comples terrain.

5. the large gronud area ,color steel tile roof and etc.

6. thefirst input only need 2 years to recover costs,and the investors will receive10-30% annual generating incomes more than 20 years.

•installed capacity | • 1KW—10KW |

•control method | •Light control •time control •light/time control |

•tracking accurancy | • ≤1° |

•Azimuth angle | • ±45° |

•Working wind | • 50—70km/h |

•Max wind resistance | • 125—200km/h |

•Driven power | • DC24V/≤30W |

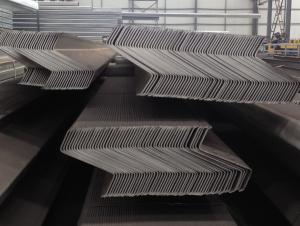

•Structural material | • Q 2 3 5 •hot-dip galvanized steel |

•level of protection | • IP65 |

•Quality guarantee | • 25Y/2Y |

•Operating ambient temperature | • -35℃—65℃ |

•Area of net rack | • 10㎡—80㎡ |

•Unit weight | • 200kg——2000kg |

- Q: Can solar mounting systems be installed on tiled or clay roofs?

- Yes, solar mounting systems can be installed on tiled or clay roofs. There are specific mounting systems designed to accommodate different roof types, including tiled or clay roofs. These mounting systems are designed to securely attach the solar panels to the roof without damaging the tiles or clay. Proper installation techniques and equipment ensure that the solar mounting system is safe and effective on tiled or clay roofs.

- Q: Can a solar mounting system be used with solar-powered gate openers?

- Yes, a solar mounting system can be used with solar-powered gate openers. The solar mounting system provides a secure and stable platform for installing solar panels, which in turn power the gate openers. This allows for a sustainable and eco-friendly solution for operating gate openers, reducing reliance on traditional power sources.

- Q: Can a solar mounting system be used with solar-powered ships?

- Yes, a solar mounting system can be used with solar-powered ships. These mounting systems are designed to securely hold solar panels in place and can be adapted for use on ships. By installing solar panels on ships, the solar mounting system enables the ship to generate clean and renewable energy from the sun, reducing its dependence on traditional fuel sources and making it more environmentally friendly.

- Q: Can a solar mounting system be used in areas with limited access to skilled labor?

- Yes, a solar mounting system can be used in areas with limited access to skilled labor. Many solar mounting systems are designed to be easy to install and require minimal expertise. They often come with detailed instructions and can be assembled using basic tools. Additionally, there are training programs and resources available to help educate local communities on solar installation techniques. This enables the system to be installed and maintained by individuals with limited technical knowledge, increasing accessibility to solar energy in remote or underserved areas.

- Q: Can a solar mounting system be used on awnings?

- Yes, a solar mounting system can be used on awnings. However, it is important to ensure that the awning structure is strong enough to support the weight and withstand the additional stress caused by the solar panels. Proper installation and structural reinforcement may be required to ensure the safety and stability of the system.

- Q: Can a solar mounting system be used with solar-powered signage?

- Yes, a solar mounting system can be used with solar-powered signage. The solar mounting system provides a secure and efficient way to install solar panels, which are necessary for powering solar signage. This system ensures proper positioning and stability of the panels, maximizing their exposure to sunlight and optimizing their power generation capabilities.

- Q: Are there any specific requirements for installing solar mounting systems in earthquake-prone areas?

- Yes, there are specific requirements for installing solar mounting systems in earthquake-prone areas. These requirements typically include the use of specialized mounting systems that are designed to withstand seismic activity. The systems must be designed and tested to meet certain structural standards, ensuring that they can withstand the forces and vibrations generated during an earthquake. Additionally, proper anchoring and bracing techniques must be employed to ensure stability and prevent the panels from dislodging during seismic events. It is important to consult with experts and adhere to local building codes and regulations when installing solar mounting systems in earthquake-prone areas.

- Q: Can a solar mounting system be used in areas with high winds?

- Yes, a solar mounting system can be used in areas with high winds. However, it is crucial to ensure that the mounting system is designed and engineered to withstand the specific wind conditions in the area. This may involve using appropriate anchoring techniques, robust materials, and reinforced structures to ensure the stability and safety of the solar panels in high winds.

- Q: What is the weight capacity of a solar mounting system?

- The weight capacity of a solar mounting system can vary depending on various factors such as the type of mounting system, the material used, and the specific design. However, most standard solar mounting systems have a weight capacity of around 2,000 to 10,000 pounds, which allows for the installation of multiple solar panels and ensures the system's stability and durability.

- Q: How do you choose the right solar mounting system for your project?

- To choose the right solar mounting system for your project, consider factors such as the type and size of solar panels, the location and orientation of the installation site, the available budget, and any specific requirements or constraints. Additionally, research and compare different mounting system options, evaluating their durability, ease of installation, compatibility with your specific project, and any certifications or warranties they may have. Seeking advice from solar professionals or consulting with reputable solar companies can also help in making an informed decision.

Send your message to us

Carport Solar Mounting System with Large Scale Ground Joint Horizontal Axis Tracking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords