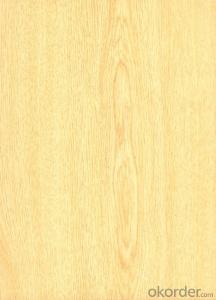

Laminate Flooring 8mm Export to Europe A Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Laminate flooring is a multi-layer synthetic flooring product, fused together with a laminationprocess. Laminate flooring ismost often four layers of materials,From topto bottom is Durable Overlay, Decorative Paper, HDF board, Balance Paper.

Durable Overlay is made by applying an AL2O3 solution over transparent paper, AL2O3 is very fineand thus it does not hide the color and design of the decorative paper.

Decorative Paperis a computer made paper which imitates natural wood, stone etc, by applying AL2O3to decorative paper, the latter becomes protected from the environment.

HDF board are made of wood fiber compressed into a high density panel (≥880kgs/m3).

Balance Paper is the thick and strong paper treated with AL2O3 on the back of laminate flooring,it gives stability to the laminate flooring boards and provide a measure ofisolation from under-floor humidity.

Wear Rating:

Durable Overlay Thickness | Applying Place | Euro Grade | EN438 | EN13329 | China National Stand |

22g/m2 | 21 Family Low Grade | AC1 | 2000 | ≥600 | 1500 |

33g/m2 | 22 Family Medium Grade | AC2 | 4000 | ≥900 | 2500 |

39g/m2 | 23 Family High Grade | AC3 | 6000 | ≥1800 | 4000 |

45g/m2 | 31 Commercial Low Grade | AC3 | 9000 | ≥2500 | 6000 |

62g/m2 | 32 Commercial Medium Grade | AC4 | 12000 | ≥4000 | 9000 |

76g/m2 | 33 Commercial High Grade | AC5 | 15000 | ≥6500 | 12000 |

Formaldehyde Emission:E1

Moisture Content:≤12%

Surface: Mirror, Middle Emboss, Fine Emboss, Crystal, Hand Scraped

Specification:

Thickness: 7.3mm,8.3mm, 12.3mm, 15.3mm

Based on order, other specification are alsoavailable.

Packing: 8-10 pieces per carton, 35-60 cartons perpallet, about 20 pallets per container.

- Q: How to choose a solid wood flooring

- Solid wood flooring is generally divided into three layers of solid wood and multi-layer solid wood. Three-tier solid wood prices are higher than the multi-layer solid wood, the general skin has 0.6,0.8,1.2,1.8,2.0 mm, the cost of skin will be high, followed by the use of plastic, and some manufacturers that no formaldehyde, I personally feel no Letter, as long as there will be useful plastic formaldehyde, the landlord said that the opposite, the Finnish too Seoul plastic is also called non-aldehyde glue, the general point of the factory and have to do the export of the factory are doing this glue, this glue made out Of the formaldehyde content of the product is very small, you can rest assured that use.

- Q: Home before the shop floor of the composite floor, there is a room under the bed is always moldy, with a dry towel, the towel will have a damp feeling, can be gallbladder broom prostitutes poor Wei Wei is the floor is not deformed. Does anyone know what reason? Questions added: there is usually the room that no one lived. More

- If it is solid wood flooring, there may be long hair, but first of all to find out the corner of the wet moldy reasons, usually such a situation there are several possible, 1, the ground back tide, waterproof layer did not do well, Pipe water leakage, 3, the ground water is not good, the ground water into the wall solid wood flooring maintenance of solid wood flooring to do moisture maintenance, in addition to a simple timely window, often ventilation, there are more professional methods: Care. Should be half a year or a year to play a wax, so you can make the solid wood flooring to avoid the rainy season when the invasion of moisture, so as to achieve the purpose of extending life. Usually in the care of solid wood flooring should also be careful not to let moisture into the solid wood flooring. When found solid wood flooring surface mildly when the time can be used in a timely manner with a soft bleach to 1: 3 dilution ratio of mixed wipe, and then wipe clean cloth.

- Q: What is the padded floor under the composite floor?

- What is the padded floor under the composite floor?

- Q: In general, the thickness of the solid wood composite floor for how much

- The thickness of the parquet is generally 12 mm and 15 mm (the cost is slightly higher, the foot feel slightly better, the price is slightly expensive), these are the normal specifications: First, the main advantages of solid wood flooring, the surface selection of fine trees In addition to the above mentioned grade, is to emphasize its stability; because of his special structure, the general for more than 7 layers, the use of criss-cross the bonding mode , So easy to deformation, while for geothermal is also a very good choice; Second, the solid wood flooring in accordance with the structure can be divided into two, one for the three solid wood (three: the surface of 3-5 mm hard wood layer) One for the multi-layer solid wood (surface of 0.3-0.5 mm of precious wood veneer, the other more than 7 layers for the criss-crossing mixed wood).

- Q: Solid wood flooring must use solid wood baseboard?

- No one is required to be solid wood foot line, pvc can, that is, the provision of the skin can be transferred Jiu Xue snow effect is not good, the color is very poor, if the solid wood foot line, the color and the door is similar, so the overall effect is particularly good

- Q: My family is preparing to decorate, is considering the floor or floor tiles, we intend to live with the room with the room is also a rough dwarfed gnome dumplings evil spear pave the floor, but a friend said my house east-west, sunny, afraid of the floor can not stand Alice Is it really like this? There is a large living room area, the floor is assembled. Easy to loose more

- can..........

- Q: Thinking of replacing 12X12 vinyl kitchen covering.Plz. give highlites of the install and if you liked the results.Thnx.

- looks real good so far most difficult decision was where to start I started in the doorway did two rooms

- Q: A square 80 yuan floor budget, with a composite wood floor or a large tiles good? Please introduce the brand

- Choose a composite floor bar Floor tiles, where the cement and sand materials and paving the cost of artificial waste after the remaining 60 yuan, and 60 yuan per flat tiles can only buy low-grade tiles, color and specifications do not have much choice. And tiles of different wall tiles must also be durable and not fade but low-grade brick is difficult to meet the quality requirements. Select the composite floor of the substrate to consider the substrate is better, the election is a large sub-substrate to do the quality of the composite floor can be, and not necessarily selected brand, first asked the supplier floor substrate.

- Q: And the floor of the floor is low, you have to raise the door frame, tile workers do not want to lift the door when the workers, leveling down the door when the pressure down one centimeter of cement, so that the door Can you lay the floor?

- The key is the landlord you do not like to play seesaw, composite flooring is floating on the ground, so in fact the requirements of the ground may be higher than the solid wood floor.When you are uneven floor to the floor is large and small seesaw. The basic decoration can do it, your Haifa fried box Curcuma Valley Feng greedy fuel Kai decoration team has the final say or you have the final say ??

- Q: Home decoration to shop composite floor, in the decoration of the city to see a very bright surface of the composite floor, the effect and the wax on the same as the solid wood flooring, and even bright. Called mirror floor. Do not know this floor can not buy, what exactly what the surface painted, so bright. How about the wear resistance, will not be a long time there is irreparable wear marks. Who is the home of the power ridge ding boge hi gong but the fence of this floor, please come to a proposal. Thank you More

- Wear resistance is not good, bright just used okay, with some of the time is not so bright, it is best to consider matt, because the time will not have much change, wear marks are not very clear, This is a good friend to tell me what you think about

Send your message to us

Laminate Flooring 8mm Export to Europe A Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords