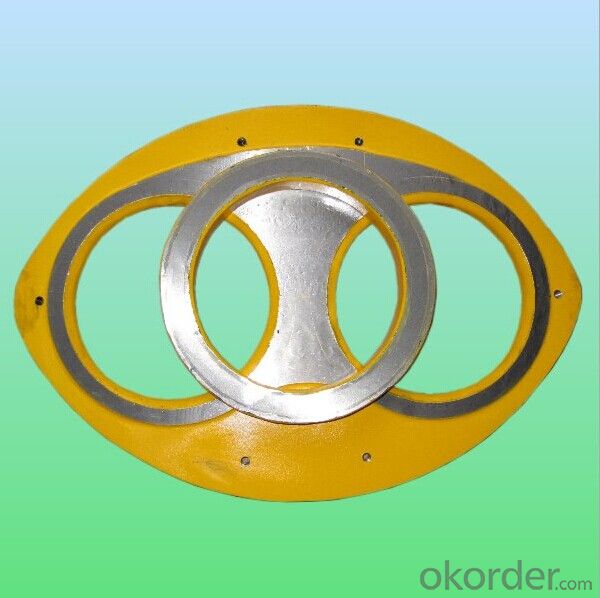

Kyokuto DN230 Spectacle Plate and Wear Ring

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Kyokuto DN230 Spectacle Plate and Wear Ring

Specifications

material: Tungsten carbide

model number: DN200/DN230

wear-resistant

long service life

high security

Product Description

Kyokuto concrete pump wear plate/Concrete pump spectacle plate

1. Material: tungsten carbide E5 grade, S35C (GB:35, DIN:C35,ASTM:1035 steel body ( or as your requirements)

2. Lifetime: 30,000~60,000cbm

3. HRA≥86 ( or as your requirements)

4. Germany Welding rod used for hardfacing ( or as your requirements)

5.tensile strength ≥ 2600 N/mm2 ( or as your requirements)

Product Detail

Size | Description |

DN180 | Shot concrete pump wear plate and wearing |

DN200 | Small mouth for trailer concrete pump wear plate and wearing ring |

DN220 | C valve 4 parts including wear plate,wear ring,round disc,long strip |

DN230 | Big mouth foe truck mounted concrete pump |

S pipe | Fitting to small and big mouth wear plate |

- Q: Where was the construction machinery conference held in 2015?

- 2015 Bada international construction machinery exhibition, exhibition information time: June 5, 2015 (Friday) - 7 day (Sunday) location: Shandong Bada international engineering machinery City Theme: cooperation, win-win, innovation, development, guidance: National Quality Supervision and inspection center of engineering machinery, Shandong Machinery Industry Association, Shandong province transportation and Logistics Association Shandong, Shandong Jiaotong University, Shandong Institute of road, economic development zone of Qihe Province

- Q: What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- Major technical equipment refers to the technical difficulty in equipment manufacturing, complete and strong, is of great significance, has a significant impact on the national economy need to be beneficial to the people's livelihood, complete sets of major technical equipment organizations across sectors, industries and regions to complete.

- Q: What are the principles, performances and uses of the commonly used construction machinery equipment?

- 3. excavator principle: Excavator through the hydraulic pump to the power of the engine to hydraulic motors, hydraulic cylinders and other executive components, to promote the operation of the device, so as to complete all kinds of operations. Performance: new Isuzu engine, euro II emission, international standards, more into power for you, lower fuel consumption; with high torque rotary mechanism, improve the starting torque of rotary and rotary reducing drift; with a new high efficiency, low noise, large displacement of the main pump, provided high efficiency machine to deal with the bad working conditions; and to strengthen the work of device according to the quarry condition, increase its reliability; strengthen the lengthened crawler frame, while reducing the ground pressure, improve the performance of the fault diagnosis system; new, prolong the overhaul cycle, reduce maintenance cost. Use: 1) building and building foundation excavation; (2) mining soil, stripping mining field covering layer; (3) the quarry, tunnel, underground powerhouse and heap loading operation in the field of material; 4) excavation channel, canal and waterway dredging; (5) replacement of the devices can be pouring lifting and installation, piling, rammed earth etc..

- Q: Building materials, equipment, components and fittings products must have "three certificates" is what cards?

- Product quality certification, also known as product certification, internationally known as qualified certification. According to the 1991 implementation of the "people's Republic of China Quality Certification Management Regulations", the product quality certification is based on the product standard and relevant technical requirements, the certification institution confirmed by the certification and certification marks to prove that a particular product is in conformity with the relevant standards and technical requirements of the corresponding activities.

- Q: What type of industry does the machinery and building accessories processing belong to?

- There are only three tax categories in our country: 1 consumption tax, 2 VAT, 3 special tax (agriculture). Therefore, as long as the manufacturing or processing of industrial value added tax on enterprises. It has nothing to do with the economic nature, classification and categories of an enterprise.

- Q: How do the welding parts in the welding drawings of the machine parts indicate the technical requirements of the drawings?

- With what groove related, open groove is not the same, marking is not the same, "welding structure" reference to our specialized courses

- Q: Where are the mechanical pressurization air supply facilities set up?

- When the smoke proof staircase and antechamber antechamber, fire elevator or common antechamber parts can be opened outside the window, can use the natural ventilation, resulting in a stairwell with or common antechamber in the use of natural smoke exhaust with pressurized air supply arrangement of diversified combinations, and the two exhaust can not be shared.

- Q: What is a door rack for a construction site? How high is it generally?

- Construction machinery network learned that the door scaffolding in our country production and use of time is not long, the scaffolding developed by the various research institutions, self-contained, and not common, varieties, specifications and diverse. Some factories copy foreign products and use the imperial size.

- Q: Where are the hanging baskets for the building?

- It is strictly prohibited to use hanging baskets as vertical transport facilities for personnel and materials; no staff member is allowed to climb from a basket to a B basket

- Q: What are the construction materials, components, fittings and equipment in construction?

- 3. Equipment: a complete device which belongs to the unique function of each function of the construction project. There are systems, equipment and conventional equipment, such as: elevator, automatic fare collection, HVAC, gas fire protection, etc..

Send your message to us

Kyokuto DN230 Spectacle Plate and Wear Ring

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords