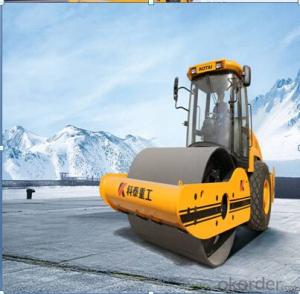

KS255S fully hydraulic single drum vibratory roller

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Note1: Padfoot is optional to all the fully-hydraulic single drum vibration rollers with double drives.

● A Professional and leading manufacturer for hydraulic road rollers, many years experience for road construction machineries.

● The factory covers an area of 140,000 square meters with more than 600 employees. Annual production capacity is 5000 sets of hydraulic road rollers.

● The company integrates R&D, production, sales and service.

● Production complies with IS09001 quality management system.

● First-class configuration can meet various request from customers.

● Products have been exported to more than 50 countries in the world.

Due to continual improvement of technologies, the technical specifications are subject to change without prior notice.

Main Features

Main Features

SAUER driving and vibration system brings the stability and reliability.

Imported vibration bearing, “three prevention” electric plugs are of good quality

Fully hydraulic Transmission and Fully electrical-hydraulic control facilitates the operation and enhances the automation.

The walking is driven by hydraulic motor, and the monolever-controlling and CVT facilitates the operation.

Double frequency and double amplitude vibration makes sure the excellent effectiveness of compaction.

Fully-hydraulic articulated steering

Maintenance-free battery cell facilitates the maintenance.

Automatic power shutting off for braking can make sure the safety and reliability.

The stream line configuration and upturning engine housing are complined with people's aesthetic standard.

项目 Item | 单位Unit | 参数Specifications |

工作质量 Operating weight | kg | 25000 |

静线载荷 Static linear load | N/cm | 570 |

振幅 Amplitude | mm | 1.98/0.99 |

振动频率 Vibration frequency | Hz | 28/32 |

激振力 Centrifugal force | kN | 405/275 |

速度范围 Speed range | km/h | 0-8.5 |

爬坡能力 Gradeability | % | 35 |

转弯半径 Turning radius | mm | 7000 |

振动轮宽度 Drum width | mm | 2150 |

振动轮直径 Drum diameter | mm | 1550 |

最小离地间隙 Min. ground clearance | mm | 486 |

发动机型号 Engine model | - | SDEC |

功率 Rated power | kW | 147 |

燃油箱容量 Fuel tank capacity | L | 300 |

转向角 Steering angle | - | ±32° |

摇摆角 Swing angle | - | ±12° |

外型尺寸(长X宽X高) Overall dimensions (L×W×H) | mm | 6400x2390x3100 |

- Q: What is static roller mill and what's the difference between vibratory roller and vibratory roller?

- It's the wrong place. The roller compactor is just compacting the road through the weight of the roller. The vibratory roller adds vibration energy to the ground through its own gravity

- Q: What is the advantage of vibratory vibratory roller in comparison with vibratory roller?

- Vibratory roller is more widely used than vibratory roller. As the bridge deck is not suitable for vibration compaction of asphalt compaction and repair, vibration and oscillation roller can be used oscillatory compaction.

- Q: The basic parameters of key Guiqiu YZ22G vibratory roller wheel vibration is quality, width, diameter, vibration, amplitude and frequency in YZ22GH and YZ22G have what different vibration wheel diameter and width parameters of the same? Related books have not been found on the Internet and can not find any help. Thank you

- The Y in YZ18 stands for the phonetic abbreviation of the press of the rollerZ stands for vibration as a phonetic abbreviation18 representative work is when the car weight is filled with water, oil and a 100KG driving hand car weight is 18 tonsYZ20C in front of YZ20 means the same as above.

- Q: The roller ensures a good compaction, usually several times

- The roller ensures a good compaction, usually 3 times

- Q: The impact roller has high production efficiency

- 1. hourly compaction can be as high as 20000 square meters.2. average working speed is 10~15 kilometers per hour.

- Q: How do the rollers see dual vibration, single vibration, double drive, single drive, double steel single steel?

- There is only one drive motor for single drive.Double vibration means that a vibration motor is arranged on the side of the front and rear two steel wheels, and the vibration motor can drive the eccentric shaft inside the steel wheel to generate centrifugal force so as to realize vibration compaction. Single vibration is that there is only one vibration motor (in front or rear wheels).

- Q: Vibratory roller pressure and steel roller compacted what is different

- You should make the cement stabilized layer of double steel wheel vibratory roller, you should first use vibratory roller vibration compaction, and then do not open vibration to smooth surface. Just do not open the vibration pressure several times, the static pressure only to surface dense, but the bottom is still more loose

- Q: How many meters does this roller advance per minute? What is the area of the road that has been pressed per minute?

- 12 meters per minute, the road area under pressure is 19.2 square meters.

- Q: What does the triple wheel drive overlap the rear wheel 1/2?

- The width of the wheel roller (rear) is half a can crush the width of 31 SSR200AC-8 double wheel, double amplitude vibration mode.

- Q: What is the design principle?Experts: how to build a large machine --- roller, the internal structure of its drum (with the brief introduction of the best)? What is the design principle? What is the maximum weight of the drum at present? What kind of traction equipment do you need? Thank you very much.

- Single axle shaft type generally used in small vibratory roller, can achieve a single or two amplitude; and the shaft shaft type generally used for large and medium-sized vibroll, you can achieve multiple amplitude; welding disc plate and detachable box is widely used, but the detachable box compared with welding disc plate, the cleanliness of the oil chamber and the bearing hole concentricity is easier to achieve, can improve the service life of the bearing vibration.

Send your message to us

KS255S fully hydraulic single drum vibratory roller

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords