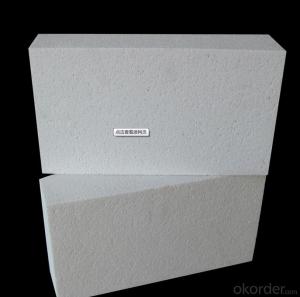

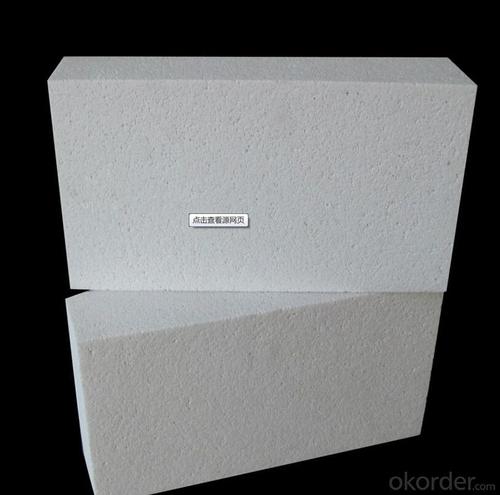

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-5

Light weight mullite insulation furnace bricks refractory for sale

Advantage

Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy savingRefractory GJM Mullite Insulation Brick B-5

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

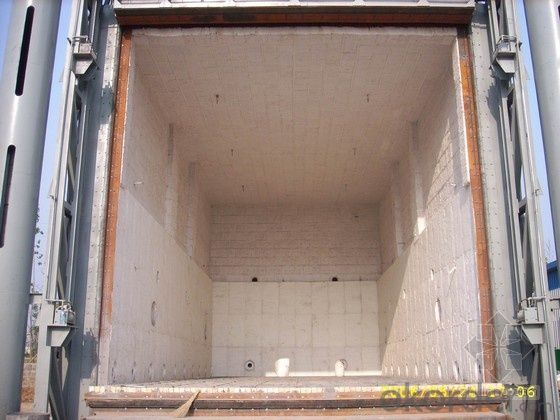

Application:Refractory GJM Mullite Insulation Brick B-5

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etcRefractory GJM Mullite Insulation Brick B-5

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very muchRefractory GJM Mullite Insulation Brick B-5

- Q: Can insulating fire bricks be used in chimney construction?

- Indeed, insulating fire bricks have the capability to be utilized in the construction of chimneys. These bricks are specifically designed to possess a low thermal conductivity, which ultimately leads to their effectiveness in minimizing heat transfer. As a result, they prove themselves suitable for chimney construction as they aid in maintaining cooler chimney walls and preventing excessive heat from being transmitted to the surrounding structures. Moreover, apart from their lightweight nature, insulating fire bricks possess commendable insulation properties, thereby making their handling and installation in chimney construction a much simpler task. However, it is imperative to acknowledge that in order to comply with safety regulations and ensure proper chimney construction, it is crucial to utilize insulating fire bricks in conjunction with other fire-resistant materials.

- Q: Are insulating fire bricks suitable for high-temperature kilns?

- Insulating fire bricks prove to be a suitable option for high-temperature kilns due to their ability to withstand extreme heat while providing excellent thermal insulation. These bricks are specifically designed to meet the demands of kilns that operate at high temperatures. They are constructed using lightweight and porous materials like clay or silica, which possess low thermal conductivity. Consequently, heat is effectively trapped within the kiln, preventing any loss, while simultaneously offering insulation against the external environment. Furthermore, insulating fire bricks exhibit remarkable resistance to thermal shock, allowing them to endure sudden temperature fluctuations without any damage. Hence, these bricks are a dependable and efficient choice for high-temperature kilns.

- Q: Are insulating fire bricks resistant to flame penetration?

- Yes, insulating fire bricks are resistant to flame penetration.

- Q: Are insulating fire bricks eco-friendly?

- To some extent, insulating fire bricks can be considered environmentally friendly. These bricks are typically crafted from abundant natural materials like clay, shale, and other fire-resistant minerals. The manufacturing process involves firing the bricks at high temperatures, which can consume a lot of energy. However, advancements in manufacturing techniques have mitigated the environmental impact by using more efficient kilns and recycled materials. Furthermore, insulating fire bricks boast a long lifespan and can endure high temperatures. This means they require less frequent replacement compared to other brick types, resulting in reduced waste generation and resource consumption over time. Moreover, these bricks possess exceptional thermal insulation properties, which can contribute to decreased energy consumption in various applications. By minimizing heat loss, insulating fire bricks can enhance energy efficiency and reduce carbon emissions in both buildings and industrial processes. Nevertheless, it is crucial to note that the eco-friendliness of insulating fire bricks also hinges on their proper disposal at the end of their life cycle. If not recycled or disposed of appropriately, they can contribute to landfill waste and potential environmental pollution. In conclusion, while insulating fire bricks offer certain environmentally friendly features, such as being made from natural materials and their energy-saving properties, their overall environmental impact also depends on responsible manufacturing, usage, and disposal practices.

- Q: Are insulating fire bricks safe to use?

- When used correctly and according to the manufacturer's instructions, insulating fire bricks are generally safe to use. These bricks are specifically designed to endure high temperatures and provide exceptional insulation, making them perfect for applications like lining kilns, furnaces, and fireplaces. Made from lightweight materials like alumina, silica, and other refractory materials, insulating fire bricks aim to minimize heat transfer, thus preventing the escape of heat from the enclosed area. This not only enhances the system's energy efficiency but also reduces the risk of overheating and potential fires, improving safety. To ensure the safe use of insulating fire bricks, it is crucial to install them properly and securely. This involves providing sufficient support and reinforcement to prevent collapse or shifting of the bricks. Additionally, it is essential to use suitable mortar or refractory cement to firmly join the bricks together, creating a sturdy and stable structure. While insulating fire bricks themselves are generally safe, it is important to note that they may contain small amounts of trace elements or materials that can be harmful if released into the environment. Therefore, it is advisable to follow the manufacturer's safety guidelines, which may include wearing protective gloves, goggles, and a dust mask when handling the bricks. In conclusion, insulating fire bricks are a safe and dependable choice for insulation in high-temperature applications. Nevertheless, it is crucial to take necessary precautions during installation and adhere to safety guidelines to ensure their proper and safe use.

- Q: Are insulating fire bricks resistant to saltwater?

- Insulating fire bricks are typically not resistant to saltwater. Saltwater contains high levels of salt, which can cause corrosion and degradation of the material over time. It is recommended to use refractory materials that are specifically designed to withstand saltwater environments if you are looking for a solution that is resistant to corrosion.

- Q: Do insulating fire bricks emit any harmful gases when heated?

- No, insulating fire bricks do not emit any harmful gases when heated. They are specifically designed to have excellent thermal insulation properties without releasing any harmful emissions.

- Q: There are several construction techniques for exterior wall insulation

- Exterior wall internal insulation technologyThe interior heat preservation of the wall is to place the heat insulation material on the inside of the outer wall.Advantage:1) waterproof, weather resistance and other technical indicators of finishes and insulation material requirements are not very high, gypsum board, gypsum plaster mortar can meet the use requirement, convenient;2) the internal insulation material is separated by the floor slab and is only constructed within a high storey without scaffolding;3) in the hot summer and cold winter and hot summer and warm winter zone, the inner heat preservation can meet the requirement;4) for the energy transformation of existing buildings, especially at a time when the housing sold to individuals, the whole building (source: China insulation network) or the entire district unified reform is difficult, only by the possibility of a large number of internal insulation. Therefore, in recent years, the exterior wall insulation has also been widely used.Shortcoming:1) because of beam, slab, structural column will cause thermal bridges, more heat loss;2) due to the material, structure, construction and other reasons, the cracking of the facing layer;3) it is not convenient for users to decorate two times and hang ornaments;4) occupy indoor use space;5) the energy saving of the existing buildings is very disturbing to the daily life of the residents.6) wall under outdoor climate, the temperature difference between day and night and the large temperature difference between summer and winter, easy to cause the wall cracking.

- Q: What is the typical thermal conductivity of an insulating fire brick?

- Insulating fire bricks possess a typical thermal conductivity ranging between 0.2 and 0.6 W/m·K, which attributes to their effectiveness as insulators by reducing heat transfer through the bricks. These bricks are specifically engineered to offer exceptional thermal insulation, enabling them to retain heat and endure high temperatures while minimizing energy loss.

- Q: Can insulating fire bricks reduce heating or cooling costs?

- Insulating fire bricks possess the ability to decrease heating or cooling expenses. These bricks are specially designed to exhibit a high level of thermal insulation, meaning they possess low thermal conductivity and can effectively hinder the transfer of heat between a building's interior and exterior. In the construction of fireplaces, ovens, or kilns, the utilization of insulating fire bricks aids in retaining heat within these structures. This enables them to achieve and maintain higher temperatures while consuming less energy. Consequently, this leads to substantial savings on heating costs, as the desired temperature can be achieved with reduced energy usage. Similarly, when employed in the construction of walls, insulating fire bricks serve to minimize heat transfer between a building's inside and outside. This results in decreased heating or cooling requirements, as the insulation helps to maintain a consistent indoor temperature. Subsequently, less energy is needed to heat or cool the building, resulting in lower energy bills and reduced overall heating or cooling expenses. It should be noted that the effectiveness of insulating fire bricks in reducing heating or cooling costs can vary based on factors such as overall building insulation, structure size and design, and climate conditions. Nevertheless, in general, the utilization of insulating fire bricks can contribute to energy efficiency and cost savings in heating or cooling systems.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords