All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

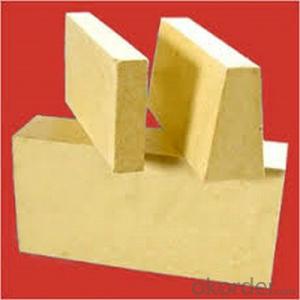

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do refractory bricks contribute to reducing emissions in industrial processes?

Refractory bricks play a crucial role in reducing emissions in industrial processes by providing insulation and heat containment, thereby increasing the energy efficiency of furnaces and kilns. The high thermal conductivity and refractory properties of these bricks allow for better heat retention, minimizing heat loss and reducing the need for excessive fuel consumption. This, in turn, leads to lower greenhouse gas emissions and a more sustainable operation. Additionally, refractory bricks can withstand high temperatures and harsh chemical environments, ensuring longer-lasting and more reliable equipment, which reduces the need for frequent maintenance and replacements, further contributing to emission reduction efforts.

How do refractory bricks resist chemical attack?

Refractory bricks resist chemical attack due to their composition and structure, which make them highly resistant to corrosive substances. They are made from materials such as alumina, silica, and zirconia, which have high melting points and can withstand extreme temperatures. Additionally, refractory bricks are dense and non-porous, preventing the penetration of chemicals. Their unique crystalline structure further enhances their resistance by forming a protective barrier against chemical reactions.

How do refractory bricks affect the efficiency of industrial processes?

Refractory bricks play a critical role in enhancing the efficiency of industrial processes. These bricks are designed to withstand high temperatures and harsh chemical environments, providing insulation and protection to the equipment and structures involved in the processes. By preventing heat loss and minimizing thermal stress, refractory bricks help maintain consistent temperature profiles, optimize energy consumption, and reduce heat wastage. Additionally, their resistance to corrosion and erosion ensures prolonged equipment lifespan and reduces downtime for repairs or replacements, ultimately improving the overall efficiency and productivity of industrial processes.

Can refractory bricks be repaired or replaced?

Refractory bricks can be repaired or replaced depending on the extent of damage. Minor cracks or chips can often be repaired using specialized refractory patching materials. However, if the damage is extensive or affects the structural integrity of the bricks, they may need to be replaced entirely.

Can refractory bricks be used in foundries?

Yes, refractory bricks can be used in foundries. Refractory bricks are known for their high heat resistance and ability to withstand extreme temperatures, making them suitable for lining furnaces and other heat-intensive equipment in foundries. These bricks help to maintain the structural integrity of the furnace and provide insulation, ensuring efficient and safe metal casting processes.

Wholesale Refractory Bricks from supplier in Panama

Thank you for considering us as your reliable supplier of Refractory Bricks in Panama. We take pride in offering top-quality products and comprehensive services tailored to meet your specific needs.

As a subsidiary platform of CNBM, a renowned Fortune Global 500 company, we have the privilege of providing you with a seamless and efficient procurement experience in Panama. Our extensive range of Refractory Bricks products ensures that you can find the perfect solution for your projects, whether it be for high-temperature furnaces, kilns, or other industrial applications.

What sets us apart is our expertise in the Panama market. Over the years, we have gained valuable experience and insights into the unique requirements of local projects. Our team of professionals is well-versed in the latest industry trends and technologies, enabling us to offer you valuable technical support and guidance.

Customer service is of utmost importance to us. Our dedicated team is committed to providing you with prompt responses and efficient solutions. From initial inquiries to after-sales support, we are here to assist you every step of the way.

Choose us as your trusted partner for all your Refractory Bricks needs in Panama, and experience the highest level of quality, reliability, and professionalism. Contact us today to discuss your requirements or to request a quotation. We look forward to serving you.

As a subsidiary platform of CNBM, a renowned Fortune Global 500 company, we have the privilege of providing you with a seamless and efficient procurement experience in Panama. Our extensive range of Refractory Bricks products ensures that you can find the perfect solution for your projects, whether it be for high-temperature furnaces, kilns, or other industrial applications.

What sets us apart is our expertise in the Panama market. Over the years, we have gained valuable experience and insights into the unique requirements of local projects. Our team of professionals is well-versed in the latest industry trends and technologies, enabling us to offer you valuable technical support and guidance.

Customer service is of utmost importance to us. Our dedicated team is committed to providing you with prompt responses and efficient solutions. From initial inquiries to after-sales support, we are here to assist you every step of the way.

Choose us as your trusted partner for all your Refractory Bricks needs in Panama, and experience the highest level of quality, reliability, and professionalism. Contact us today to discuss your requirements or to request a quotation. We look forward to serving you.

Hot Search

- Monolithic Refractories in Liberia

- Ceramic Fiber Products in Namibia

- Refractory Bricks in Slovenia

- Raw Materials For Refractory in Albania

- Ceramic Fiber Products in Chile

- Monolithic Refractories in Bulgaria

- Monolithic Refractories in Palestine

- Ceramic Fiber Products in Argentina

- Refractory Bricks in Nigeria

- Monolithic Refractories in Latvia