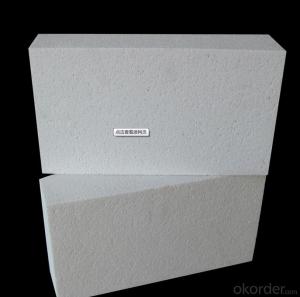

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-3

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-3

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:

Refractory GJM Mullite Insulation Brick B-3

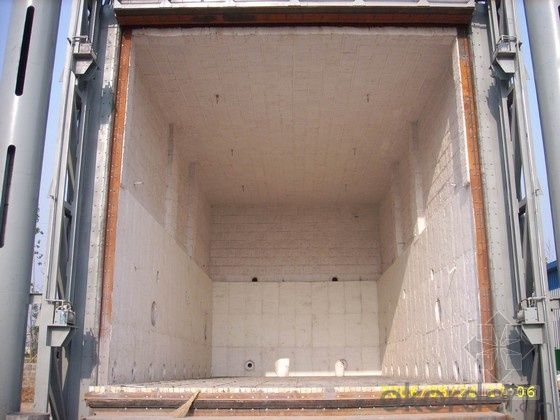

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc

Refractory GJM Mullite Insulation Brick B-3

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

Refractory GJM Mullite Insulation Brick B-3

- Q: How do insulating fire bricks affect the overall fire safety of a structure?

- Insulating fire bricks greatly enhance the fire safety of a structure. Due to their high thermal resistance, these bricks effectively prevent the spread of heat, reducing the risk of structural damage and minimizing the chance of fire spreading to adjacent areas. Additionally, their low thermal conductivity helps to retain heat within the furnace or fireplace, improving energy efficiency and reducing the likelihood of accidental fires.

- Q: Is it possible to recycle broken insulating fire bricks?

- Yes, it is possible to recycle broken insulating fire bricks. Insulating fire bricks are commonly made from materials such as clay and alumina, which can be recycled. The broken bricks can be crushed into small particles or ground into a fine powder, and then mixed with other materials to create new bricks or other construction materials. Additionally, some recycling facilities may accept broken insulating fire bricks and process them for reuse in other industries. Recycling broken insulating fire bricks helps to reduce waste, conserve resources, and minimize the environmental impact associated with manufacturing new bricks from scratch.

- Q: What are the main components of insulating fire bricks?

- Insulating fire bricks usually consist of a blend of alumina, silica, and assorted lightweight additives. Alumina (Al2O3) is crucial in insulating fire bricks due to its ability to withstand high temperatures and resist thermal shock. Silica (SiO2) contributes to improving the refractory qualities and insulation abilities of the bricks. Furthermore, vermiculite or perlite, which are lightweight additives, are commonly incorporated to enhance the insulating properties of the bricks. The collaboration of these components produces a material that possesses exceptional thermal insulation, minimal thermal conductivity, and remarkable heat resistance.

- Q: Do insulating fire bricks expand and contract with temperature changes?

- Yes, insulating fire bricks do expand and contract with temperature changes.

- Q: Are insulating fire bricks suitable for use in oil refineries?

- Insulating fire bricks are generally not suitable for use in oil refineries. While insulating fire bricks are designed to withstand high temperatures, they are not resistant to the corrosive and abrasive nature of oil and its byproducts. Oil refineries involve a complex process of refining crude oil into various petroleum products, and this process often exposes the materials used in the refinery to harsh chemicals and high temperatures. Instead, oil refineries typically use refractory bricks or castables that are specifically designed to withstand the corrosive and abrasive conditions found in the refining process. Refractory materials used in oil refineries are resistant to chemical attack, have high strength and thermal shock resistance, and can withstand the extreme temperatures encountered during the refining process. Additionally, oil refineries require materials that can provide excellent insulation properties while also being durable and resistant to thermal stress. Insulating fire bricks, although they have good insulation properties, may not have the necessary durability and resistance to thermal stress required in the demanding environment of an oil refinery. Therefore, it is recommended to use refractory bricks or castables specifically designed for oil refineries, which can provide the necessary resistance to chemicals, high temperatures, and thermal stress, ensuring safe and efficient operation of the refinery.

- Q: Can insulating fire bricks be used in residential applications, such as fireplaces or ovens?

- Insulating fire bricks can indeed be used in residential applications such as fireplaces or ovens. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight materials such as clay or alumina, which have low thermal conductivity. This helps to keep the heat inside the fireplace or oven, making it more efficient and reducing energy consumption. Insulating fire bricks also have good resistance to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. Additionally, these bricks are non-combustible, ensuring they can withstand the high temperatures generated in fireplaces or ovens without posing a fire hazard. Therefore, insulating fire bricks are a suitable choice for residential applications where high temperatures and thermal insulation are required.

- Q: Can insulating fire bricks be used for insulation in heat exchangers?

- Insulation in heat exchangers can be achieved by utilizing insulating fire bricks. These bricks are constructed from a lightweight refractory material that boasts exceptional thermal insulation properties. With their low thermal conductivity, insulating fire bricks effectively minimize heat transfer between the two sides of the heat exchanger. Consequently, they aid in maintaining the desired temperature within the heat exchanger and prevent heat loss to the surroundings. Furthermore, the durability of these bricks is evident as they can endure high temperatures and thermal shocks, making them ideal for the harsh conditions typically encountered in heat exchangers. In summary, incorporating insulating fire bricks into heat exchangers not only enhances energy efficiency and reduces heat loss but also improves the overall system performance.

- Q: Can insulating fire bricks be used in the construction of smelters or foundries?

- Yes, insulating fire bricks can be used in the construction of smelters or foundries. Insulating fire bricks have excellent thermal insulation properties and can withstand high temperatures, making them suitable for lining the walls and floors of smelters or foundries. They help to retain heat, improve energy efficiency, and protect the surrounding structures from extreme temperatures.

- Q: Are insulating fire bricks resistant to insects and rodents?

- No, insulating fire bricks are not specifically designed to be resistant to insects and rodents. While these bricks are primarily used for their excellent thermal insulation properties in high-temperature applications such as furnaces and kilns, they do not possess any inherent resistance to pests. If you are concerned about insects or rodents, it is recommended to implement additional pest control measures such as sealing any gaps or cracks and using appropriate pest deterrents.

- Q: Can insulating fire bricks be used for insulation in steam boilers?

- Yes, insulating fire bricks can be used for insulation in steam boilers. These bricks are designed to withstand high temperatures and have excellent thermal insulation properties. They are commonly used in various applications that require insulation, including steam boilers. Insulating fire bricks are able to minimize heat loss and improve energy efficiency in steam boilers by providing a barrier that prevents heat transfer to the surrounding environment. Additionally, their lightweight and porous structure make them easy to handle and install in steam boilers. Therefore, insulating fire bricks are an ideal choice for insulation in steam boilers, as they help to enhance their performance and reduce energy consumption.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords