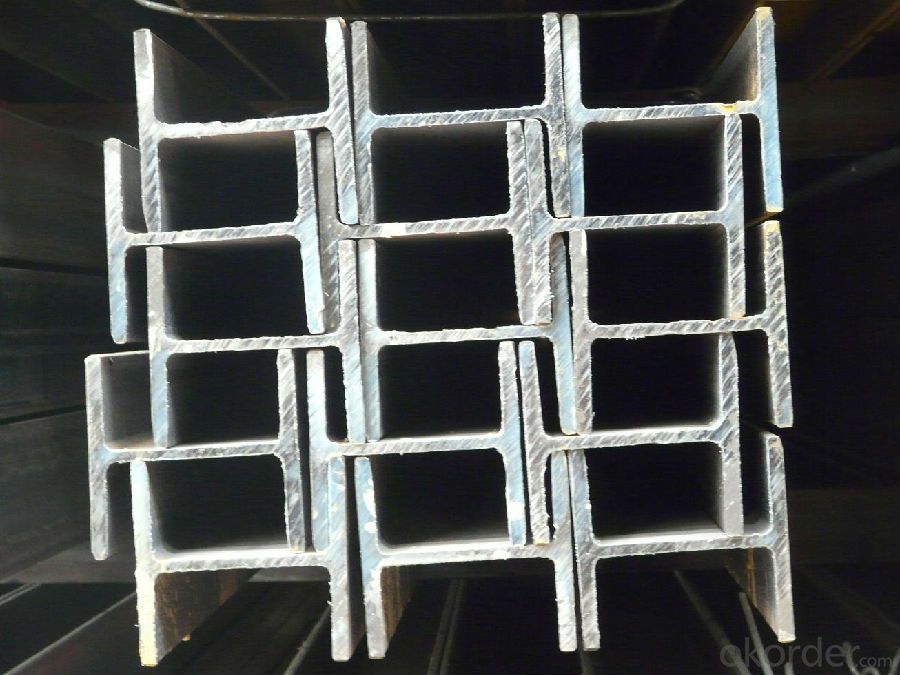

I Beam Prime Hot Rolled IPE IPEAA EN 10025 Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||

a*t | ||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do you package the angle steel when shipping?

A2: All goods are packed in bundles with steel strips and shipped by container or break bulk.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Are there any environmental concerns associated with the production of steel I-beams?

- Yes, there are several environmental concerns associated with the production of steel I-beams. Firstly, the production of steel requires a significant amount of energy. This energy is often derived from non-renewable sources such as coal or natural gas, which contribute to greenhouse gas emissions and climate change. The extraction and transportation of these fossil fuels also have environmental impacts, including habitat destruction, air pollution, and water contamination. Additionally, the process of converting iron ore into steel involves several steps that can generate pollution and waste. For example, the extraction of iron ore can lead to deforestation, habitat destruction, and soil erosion. The mining process also requires water, and if not managed properly, it can result in water pollution and depletion. Furthermore, the production of steel I-beams involves a process called steelmaking, which typically requires the use of blast furnaces or electric arc furnaces. These furnaces emit pollutants such as carbon monoxide, sulfur dioxide, and nitrogen oxides, contributing to air pollution and acid rain. The steelmaking process also generates solid waste, including slag and dust, which can contain heavy metals and pose risks to human health and the environment if not properly managed. Finally, the transportation of steel I-beams can also have environmental impacts. The heavy weight and size of these beams often require large trucks or ships for transportation, which consume fossil fuels and contribute to air pollution and greenhouse gas emissions. To mitigate these environmental concerns, efforts have been made to improve the efficiency of steel production processes, reduce emissions, and promote the use of recycled steel. Recycling steel can significantly reduce the energy and raw material requirements, as well as the associated environmental impacts. Additionally, advancements in technology and the adoption of cleaner energy sources can help minimize the carbon footprint of steel production.

- Q: Is the I-beam generally made or is it a long one?

- I-beam has custom-made, there are also ready-made, the general length of 5~19 meters.

- Q: How do steel I-beams perform in terms of load redistribution?

- Steel I-beams are incredibly efficient when it comes to redistributing loads. The distinctive shape of the I-beam, complete with flanges and a web, enables it to evenly distribute the applied load throughout its entire length. The flanges, positioned at the top and bottom of the beam, have been engineered to resist bending and compression forces, while the web, located between the flanges, is designed to withstand shear forces. When a load is placed on an I-beam, the flanges and web collaborate to spread the load across the entire length of the beam. The flanges bear the majority of the load, while the web helps combat shear forces. By redistributing the load in this manner, the beam is able to endure heavy loads without excessive deflection or failure. Moreover, steel I-beams possess a remarkable strength-to-weight ratio, making them the perfect choice for supporting hefty loads over long distances. This allows for the construction of structures with fewer support columns or walls, creating more open and adaptable spaces. To sum up, steel I-beams are exceptional at redistributing loads due to their unique shape and design. They have the ability to efficiently distribute loads along their length, minimizing deflection and maintaining structural integrity even under significant loads.

- Q: Can steel I-beams be used in the construction of residential bridges?

- Indeed, steel I-beams are suitable for use in the construction of residential bridges. Their strength, durability, and versatility make them a common choice in construction. They have the capability to support heavy loads and are well-suited for spanning long distances. Although residential bridges are typically smaller in scale compared to larger structures like highway bridges, they still require strong and reliable materials to ensure structural integrity. Steel I-beams offer the necessary strength and stability for residential bridge construction. Furthermore, steel is resistant to corrosion and can withstand various weather conditions, making it an excellent option for outdoor structures such as bridges. All in all, steel I-beams are widely favored for residential bridge construction because of their strength, durability, and ability to support heavy loads.

- Q: What's the difference between 16# I-beam and 16A I-beam?

- Due to the relatively high section size and narrow section of ordinary I-beam and light I-beam, the moment of inertia of the two main sleeves of the cross section is different greatly, which makes it have great limitations in its application. The use of I-beam shall be selected according to the requirements of the design drawings.

- Q: How do engineers determine the required size of a steel I-beam for a specific application?

- Engineers determine the required size of a steel I-beam for a specific application by considering various factors such as the load it needs to support, the span it needs to cover, and the desired deflection limits. They analyze the structural requirements using mathematical formulas, computer simulations, and industry standards to ensure the I-beam can safely withstand the anticipated forces and maintain the desired level of structural integrity.

- Q: How do steel I-beams handle dynamic loads from moving vehicles?

- Steel I-beams are highly effective in handling dynamic loads caused by moving vehicles. These beams possess exceptional strength and load-bearing capabilities, making them ideal for supporting heavy loads and enduring the dynamic forces produced by vehicles in motion. One of the main reasons why steel I-beams can handle dynamic loads is due to their high structural stiffness. The I-shaped cross-section of these beams grants them superior resistance against bending and torsional forces, ensuring their ability to effectively handle the dynamic loads exerted by moving vehicles. This structural stiffness also aids in distributing the load evenly along the beam's length, preventing localized stress concentrations and minimizing the risk of failure. Additionally, steel I-beams are typically made from high-quality, high-strength steel, further enhancing their capacity to handle dynamic loads. This type of steel possesses outstanding mechanical properties, including high tensile strength and toughness, enabling the beam to resist deformation and maintain its structural integrity under the dynamic forces exerted by moving vehicles. Furthermore, steel I-beams can be reinforced or supplemented with additional components to enhance their ability to handle dynamic loads. For example, steel plates or brackets can be welded or bolted to the beam's flanges or web, increasing its load-carrying capacity and providing extra support. Overall, steel I-beams are specifically engineered and designed to effectively handle dynamic loads from moving vehicles. Their structural stiffness, high-strength steel construction, and potential for reinforcement make them a dependable and long-lasting choice for supporting heavy loads and withstanding the dynamic forces generated by vehicles in motion.

- Q: What is the maximum span length that steel I-beams can support?

- The maximum span length that steel I-beams can support depends on various factors such as the type and size of the beam, the load it is intended to carry, and the design specifications. It is not possible to provide a specific maximum span length without considering these variables. Professional engineers and structural designers typically calculate the appropriate span length based on these factors to ensure structural integrity and safety.

- Q: What are the considerations for accessibility and universal design with steel I-beams?

- When considering accessibility and universal design with steel I-beams, several factors need to be taken into consideration. Firstly, it is important to ensure that the steel I-beams are designed and installed following the relevant accessibility guidelines and standards. This includes complying with building codes and regulations that address accessibility requirements for individuals with disabilities. These guidelines may vary depending on the country or region, so it is crucial to be familiar with the specific requirements in the project's location. Secondly, the size and positioning of the steel I-beams should be carefully planned to allow for easy movement and navigation within the space. This involves considering clearances and widths that accommodate wheelchair users and individuals with mobility aids. The I-beams should not obstruct pathways or create barriers that impede accessibility. Moreover, the material and finish of the steel I-beams should be chosen with accessibility in mind. It is important to consider factors such as slip resistance, visibility, and ease of gripping. Non-slip coatings or textured finishes can be applied to the I-beams to prevent accidents caused by slippery surfaces. Additionally, contrasting colors can be used to make the I-beams more visible for individuals with visual impairments. Furthermore, if the steel I-beams are part of a structure that requires ramps or elevators for accessibility, they need to be properly integrated into the design. The I-beams should support the weight of these features and ensure their stability and safety. Inclusive design is another crucial consideration when it comes to accessibility and universal design with steel I-beams. Inclusive design focuses on creating environments that can be used by people of all abilities and ages. It is important to involve individuals with disabilities or accessibility needs in the design process to ensure that their perspectives and requirements are taken into account. Overall, accessibility and universal design considerations for steel I-beams encompass compliance with regulations, proper sizing and placement, appropriate material selection, integration with accessibility features, and inclusive design practices. By incorporating these considerations, steel I-beams can help create spaces that are accessible to everyone, promoting inclusivity and equal access for all individuals.

- Q: What are the different types of steel I-beam connections for roof framing?

- Roof framing for steel I-beams involves various types of connections, each with its own advantages and applications. 1. One common and straightforward method is the welded connection. By welding the ends of the beams together, a strong and rigid connection is created. Welded connections are often used for heavy loads and situations where structural stability is crucial. 2. Another method is the bolted connection, where steel plates or angles are bolted to the flanges of the I-beams. This allows for easy disassembly if needed and can accommodate different beam sizes and angles, making it suitable for various roof framing designs. 3. A gusset plate connection involves welding or bolting a steel plate to the webs of two I-beams, effectively joining them together. This type of connection is commonly used in roof framing to transfer loads and provide additional strength and stability, especially in situations where load-bearing capacity and resistance against lateral forces are needed. 4. For the transfer of bending moments between two beams, a moment connection is used. This more complex type of connection involves welding or bolting additional steel plates and angles to the flanges and webs of the I-beams. Moment connections are typically used in large-span roof structures or where there is a need to resist lateral and vertical loads. 5. Cleat connections are made by attaching steel plates, called cleats, to the flanges of two I-beams using bolts or welding. This type of connection is commonly used when beams need to be joined at an angle or connected to other structural elements such as columns or walls. Cleat connections offer flexibility in design and ease of installation. When selecting the appropriate type of steel I-beam connection for roof framing, it is important to consider factors such as load requirements, structural stability, and ease of assembly. Consulting with a structural engineer or a roofing professional can help determine the most suitable connection method for a specific project.

Send your message to us

I Beam Prime Hot Rolled IPE IPEAA EN 10025 Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords