HVAC Duct Tape Foil Tape Aluminium Foil Tapes

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 roll

- Supply Capability:

- 90 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

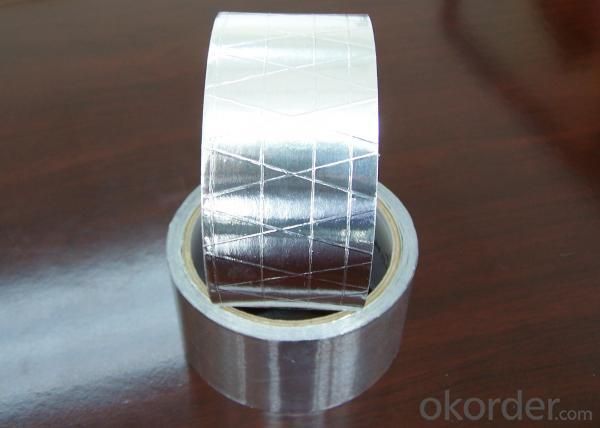

Aluminium Foil Tape Description

1. Specifications of Aluminium Foil Tape

PROPERTIES | UNIT | VALUE | TEST METHOD |

Alu Foil Thickness | micron | 30 | GB |

Adhesive Coating | g/m2 | 40 | GB |

Adhesive Type | ------- | water acrylic | GB |

Peel Adhesion | N/25mm | 11 | GB |

Rolling Tack(11mm ball) | cm | 20 | GB |

Fire Rating | ------- | Class 0 | BS476 |

Temp Resistance | °C | -20-+120 | ASTM E84 |

1) Roll length: 27m-1000m

2) Roll width: 50mm-100mm

3) Jumbo roll: 1.2m x 1,200m, 1.2m x 1,000m

2. Applications and Features of Aluminium Foil Tape

1) HVAC system for building thermal insulation,suitable for sealing seams and joints of various laminated insulation facings.

The applications include: Duct Wrap, Wall Insulation, Metal Building Insulation,

Pipe Insulation, Hot Water Tank Insulation.

2) Electronic refrigeration fields ,Used for refrigerator industry, masking operations in electroplating and paint stripping, also good at protecting cable splices, metal patching and sound dampening applications.

3. Package & Delivery of Aluminum Foil Tape

Inner packing:

Cut roll: printed core and shrink wrapping

Log roll: cardboard wrapping

Jumbo roll: plastic film + corrugated board wrapping

Outer packing:

Cut roll: carton

Log roll: carton + pallet / ply-wooden case

Jumbo roll: ply-wooden case

4. Production Flow of Aluminum Foil Tape

The main producing procedure includes the following steps:

Raw material-Adhesive Coating-lamination-Wrapuping-Cutting-Packing

5. FAQ of Aluminum Foil Tape

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: If I feel the room cool off, one hour hot and open an hour this will be more expensive? More

- No, polycyclic aromatic should be anthraquinone This is certainly not all of the hydrocarbons are carcinogenic

- Q: Air to water heater host and air conditioning host is not the same

- Issued a test report, Detection can be used to pass, failed to use!

- Q: Air conditioning ventilation when the sound is a big reason

- Buried plastic pipe under external load, the diameter of the vertical diameter deformation rate should be less than the allowable diameter of the pipe deformation rate The diameter of the allowable diameter of the pipe shall not be greater than 5% The diameter deformation rate of the pipe and the allowable diameter deformation rate are calculated as follows: ε ΔD / D0 × 100% [ε] ε0 / K where: εΔD pipe in the combined load (Mm) [ε] Permissible diameter Deformation rate ε0 Elastic diameter Deformation rate (%) of pipe, by the flattening of the diameter of the pipe diameter (mm) The test determines the K safety factor, generally desirable 15

- Q: US direct mail dysonhp01 Dyson air purification cooling machine triple in the country to warranty it

- Among them, the extruded polystyrene gypsum composite board is based on paper gypsum substrate, the use of adhesive and extruded polystyrene board through the factory processing compound

- Q: Do 3cm thick wall insulation how much kilogram of slurry and how many kilograms of polystyrene particles

- You are talking about the construction measures it is not the house measures it, because the house has a construction of Huohuohuohuo number of leather and bronze sculpture drawings and specifications, high-rise building scaffolding should be lightning protection measures, that is, under the scaffolding around Reliable grounding (not less than four times, not less than 16 square copper core BV line), if it is pick plus, and the house can be connected to the pressure ring. Tower crane I will not say, upstairs has been said.

- Q: I added the space 18 degrees opened for 5 hours or not cold, we all know how is it? More

- Common points are all sandwich panels, with a hard protective layer, the difference is the middle of the different materials, such as polystyrene board, polyurethane board. Polystyrene board which is the most common, because the price is cheap, easy to use so the use of more, but if the temperature is more than the requirements of the chicken inertia glycosylation moxibustion slim faint words, polystyrene board is not satisfied , So there is a polyurethane sandwich panels, polyurethane thermal conductivity of less than 0.. in the existing insulation materials, large quantities of processing, be the best. But because of its process is more complex, and the cost is relatively high, so with less, the common combination of cold storage and the like, I believe that with the economic and technological development, polyurethane sandwich board market share will be more and more High

- Q: Air conditioning machine work when the sound is too much reason

- Many of the good quality of the model, of course, bear some of the larger. Common scaffolding brackets are U-type care, "construction fastener steel scaffold safety technical regulations" (JGJ130-2011) provides "adjustable support bearing capacity design value should not be less than 40kN, support plate thickness should not be less than 5mm ", the general calculation using 30kN. Not to say how fast buckle steel scaffold can bear the load, but according to how much load to calculate how scaffolding erection. Need to be calculated. In the "construction of fasteners steel scaffold safety technical specifications" provides instructions. Double fastener (anti - skid) bearing capacity design value 3.2KN. Right angle fastener, rotary fastener (anti-skid) bearing capacity design value 8KN.

- Q: What is the whole heat exchange fresh air ventilator?

- Second, the new insulation decorative board is integrated through the production line, set insulation, waterproof, finishes and other functions in one, is to meet the current housing construction energy needs, improve the industrial and civil building exterior wall insulation level of the preferred material, but also on the existing Building energy-saving transformation of the preferred materials

- Q: External wall insulation method of operation There are several combinations of materials

- Seeking the existing building construction specifications Daquan! The The @

- Q: Ventilation is very good, why still have to install fresh air system

- You are a single raft toilet wipes Pie Tanzhuang open card would like to confirm what? Contract notarization or. The The If it is contract notarized, generally notary value of 0.25% -0.3%

Send your message to us

HVAC Duct Tape Foil Tape Aluminium Foil Tapes

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 roll

- Supply Capability:

- 90 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords